Method for preparing polyimide porous diaphragm

A polyimide, porous diaphragm technology, applied in electrical components, non-aqueous electrolyte batteries, circuits, etc., to achieve high yield, good high temperature resistance, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

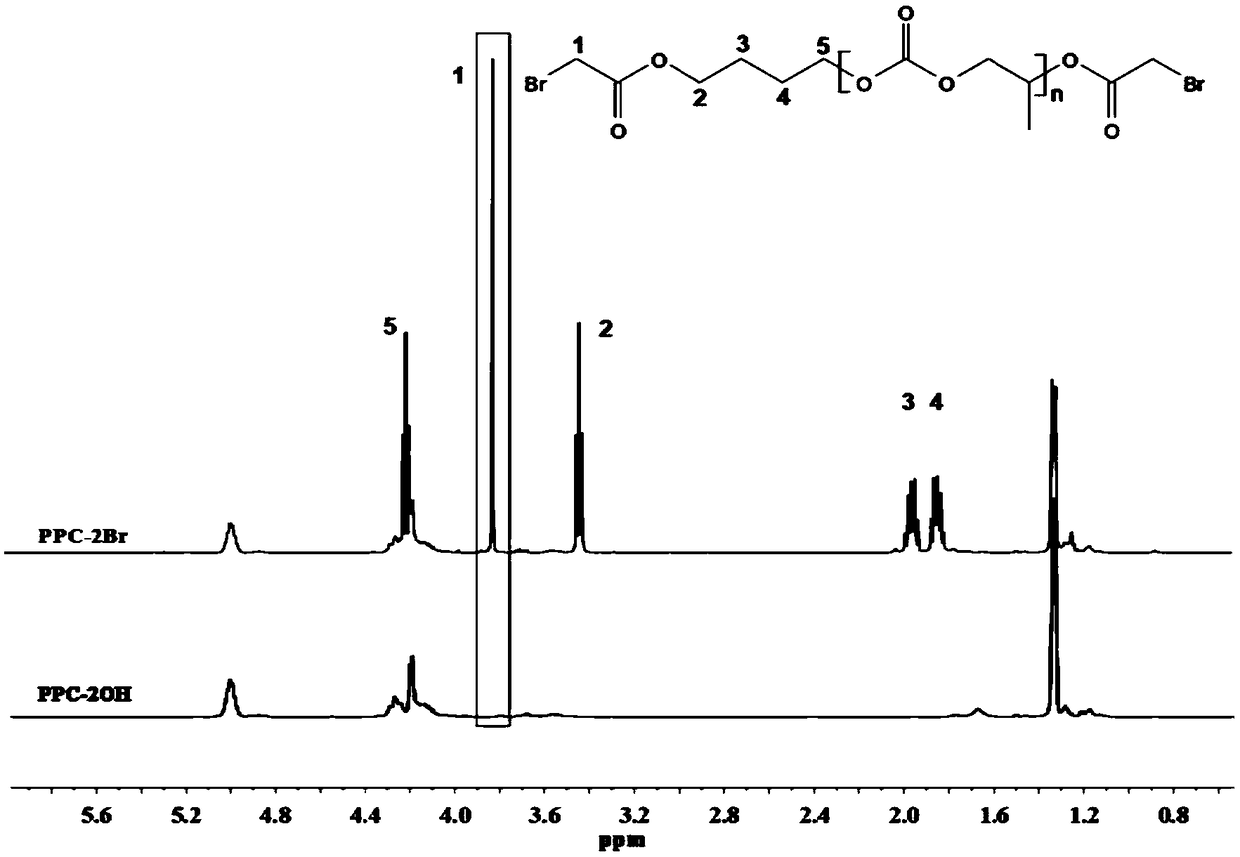

[0046] Embodiment 1: the bromine group capping reaction of thermally unstable polymer polypropylene carbonate diol.

[0047] (1) Synthesis of hydroxyl-terminated PPC (PPC-2OH)

[0048] Take 85g of high molecular weight PPC in a three-neck round bottom flask, and carry out mechanical stirring at 160°C in a nitrogen atmosphere. When the temperature is stabilized at 160°C, add 15g of 1,4-butanediol (BDO) for alcoholysis. After 2 hours of reaction Stop heating, cool to room temperature, add 50mL chloroform to dissolve the product, then add 50mL deionized water to wash, and separate the liquid through a separatory funnel to remove unreacted BDO and small molecule PPC-2OH, repeat washing more than 5 times, and The purified chloroform solution of PPC-2OH was transferred to a watch glass, and the chloroform was volatilized and removed to obtain the PPC-2OH product with a yield of ~60%. Use the titration method to measure the hydroxyl content, and calculate the relative molecular mass...

Embodiment 2

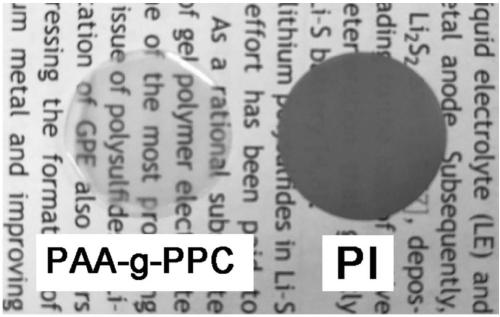

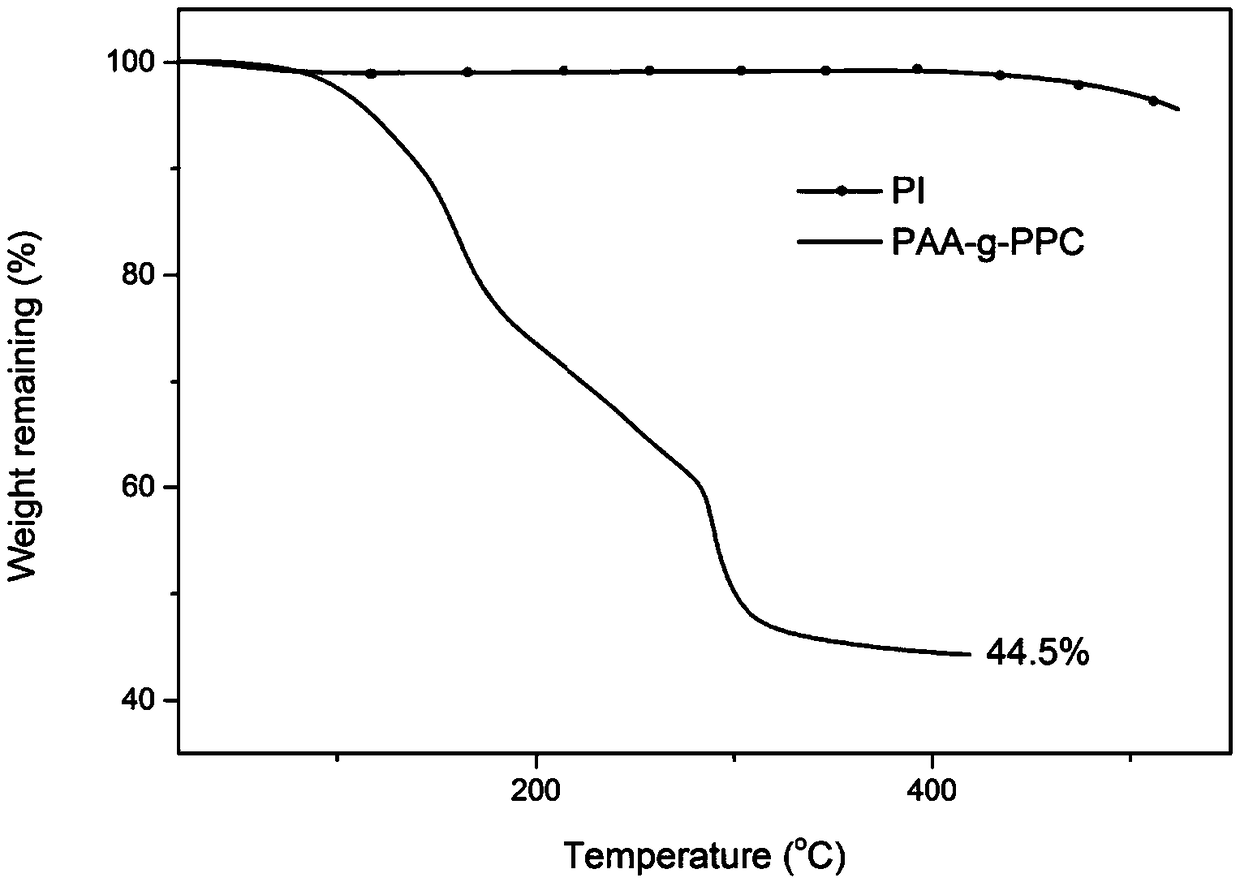

[0053] Example 2: Preparation of polyimide diaphragm using pyromellitic dianhydride and 4,4'-diaminodiphenyl ether as raw materials

[0054] Add 10mmol of diamine monomer 4,4'-diaminodiphenyl ether and 50mL of N,N-dimethylacetamide into a 150mL round bottom flask, mechanically stir at room temperature under nitrogen atmosphere until completely dissolved, then add 10mmol Pyromellitic dianhydride was reacted at room temperature for 10 hours to carry out polymerization, and after adding 10 mmol of anhydrous potassium carbonate to react for 2 hours, centrifuged to remove unreacted solid particles to obtain polyamic acid potassium salt (PAA-K + ). Concrete reaction process is as shown in reaction formula 2:

[0055]

[0056] Reaction 2 PAA-K + The reaction flow formula

[0057] Weigh 2g of 7wt.% PAA-K in a 50mL centrifuge tube + solution, add 0.15g PPC-2Br and stir quickly to make the mixture uniform to obtain a transparent solution, centrifuge at a speed of 10000r / min for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com