High-strength and high-toughness heat treatment method of medium-carbon silicon-manganese-chromium-nickel series low alloy steel

A heat treatment method and high-strength technology, applied in the field of high-strength and toughening heat treatment of low-alloy steel, can solve the problem that medium-carbon, silicon-manganese-chromium-nickel-based low-alloy steel cannot have strength and plastic toughness at the same time, and improve yield strength and elongation. , the effect of improving plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

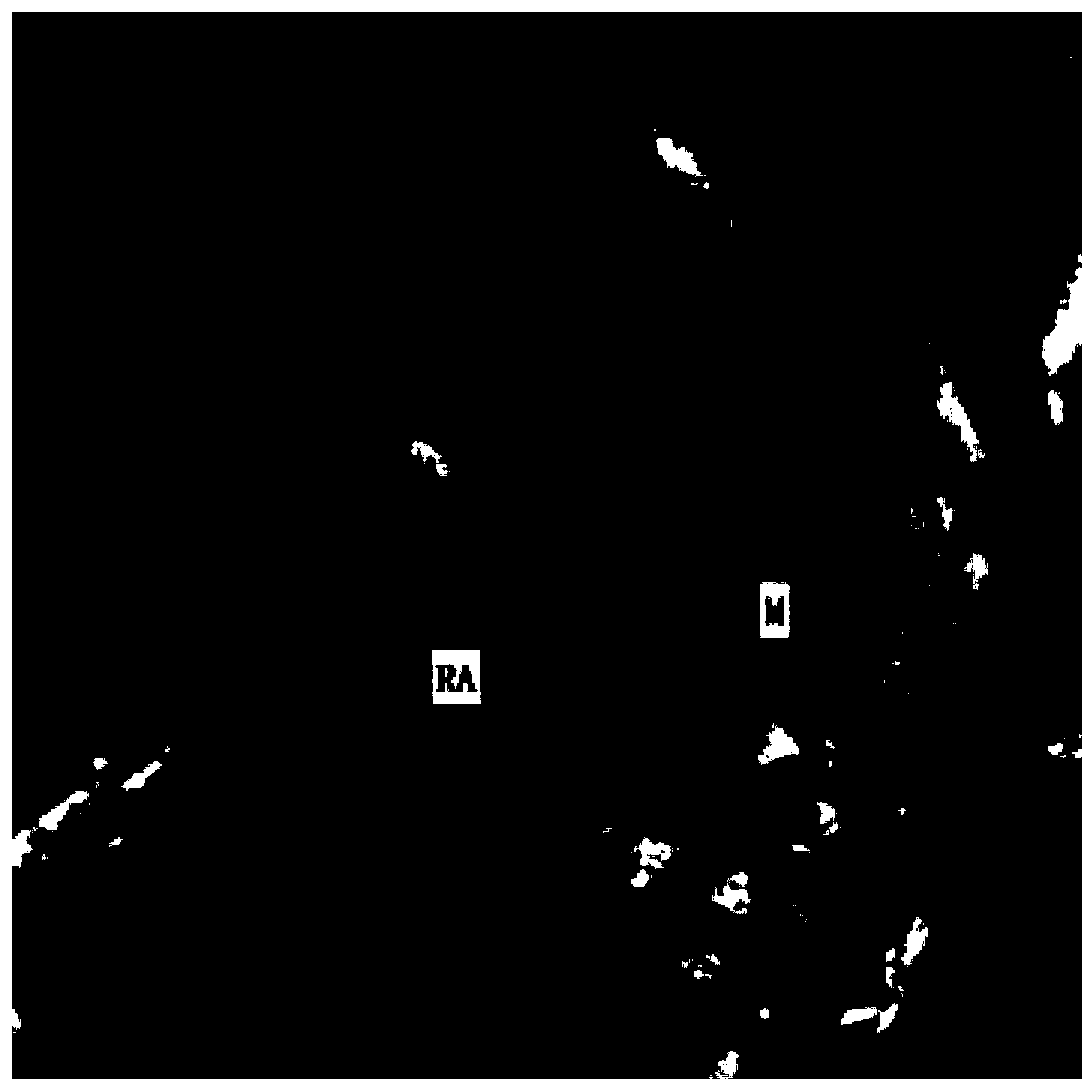

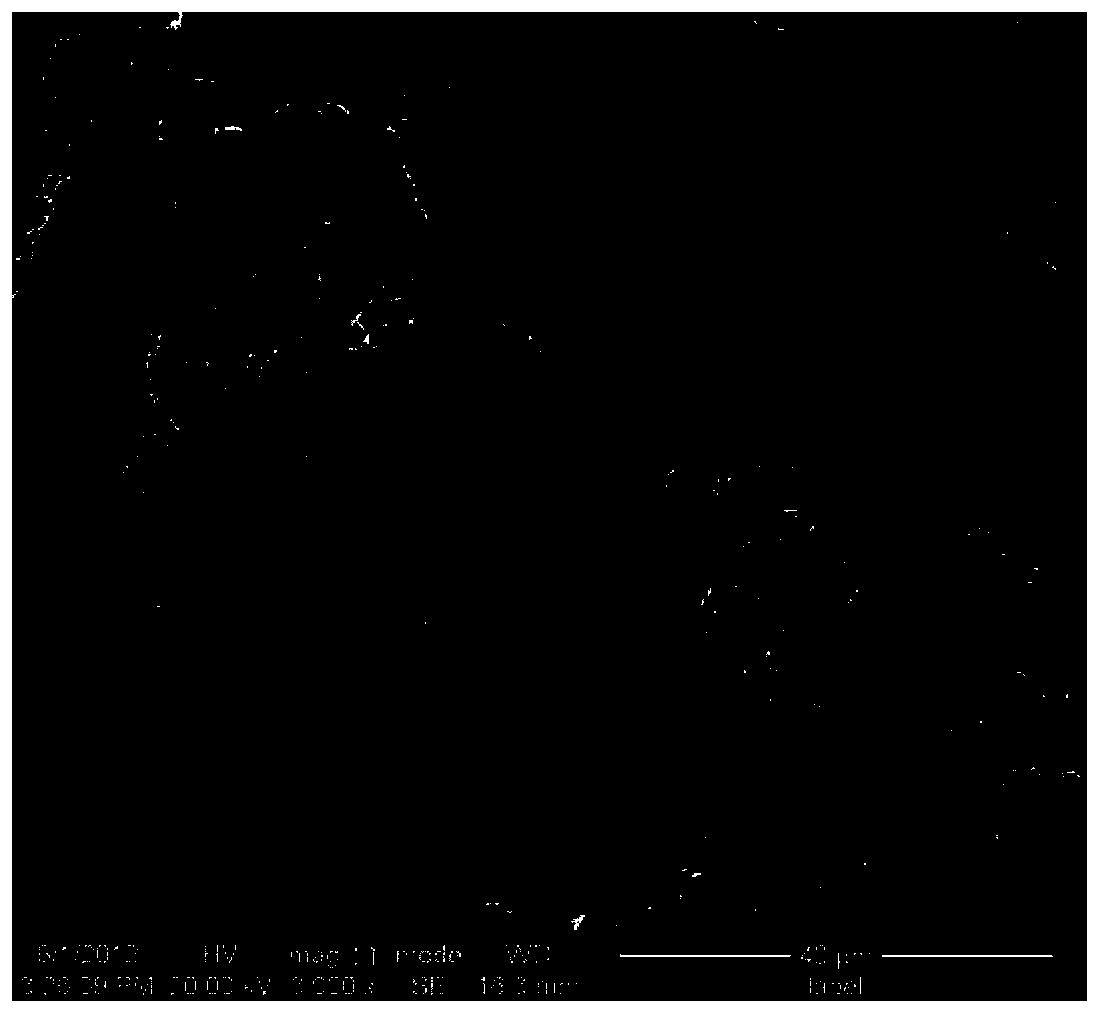

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: In this embodiment, a method for high-strength and toughening heat treatment of medium-carbon silicon-manganese-chromium-nickel low-alloy steel is carried out according to the following steps:

[0011] 1. The first heat treatment: Austenitize the medium-carbon silicon-manganese-chromium-nickel low-alloy steel, and then lower the martensitic transformation starting point Ms of the medium-carbon silicon-manganese-chromium-nickel low-alloy steel at 90°C to 10°C. ℃ for isothermal quenching, holding time is 120s, complete the first heat treatment; wherein said isothermal quenching is isothermal oil quenching or isothermal gas quenching;

[0012] 2. The second heat treatment: put the medium-carbon silicon-manganese-chromium-nickel low-alloy steel after the first heat treatment in step 1 above the martensitic transformation starting point Ms of the medium-carbon silicon-manganese-chromium-nickel low-alloy steel at 80°C to 200°C ℃ for isothermal quenchi...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific operation process of the austenitization treatment described in step 1 is as follows: the medium-carbon silicon-manganese-chromium-nickel low-alloy steel is placed at a temperature of medium carbon silicon Manganese-chromium-nickel low-alloy steel A c3 Insulation under the above conditions of 30°C to 50°C, the holding time is 600s to 1800s, that is, the austenitization treatment is completed; the A c3 It is the final temperature when ferrite is completely transformed into austenite when heated. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that the medium-carbon silicon-manganese-chromium-nickel low-alloy steel described in step 1 is 40SiMnCrNiMoV steel, 37SiMnCrNiMoV steel, 30Si2MnCrMoVE steel or 35SiMnCrMoVA steel. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com