Co3O4@PEDOT porous nanorod material with core-shell structure and preparation method of Co3O4@PEDOT porous nanorod material

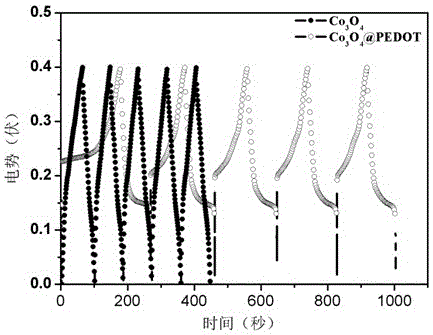

A core-shell structure and nanorod technology, which is applied in the field of core-shell structure nanomaterials and their preparation, can solve the problems of lack of electrical conductivity and application limitations, and achieve the effects of high electrical conductivity, good comprehensive performance and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

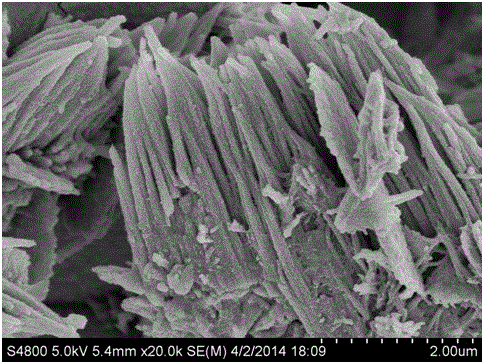

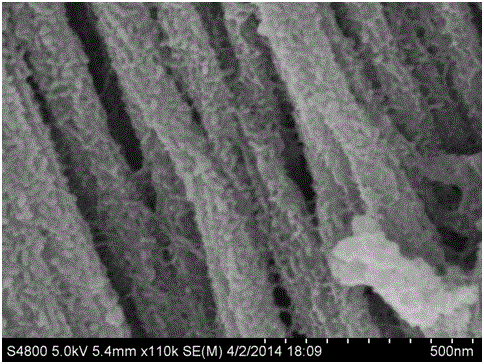

[0023] 1 Weigh cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), ammonium chloride (NH 4 Cl) and urea (CO(NH 2 ) 2 ) was dissolved in deionized water, and stirred evenly at room temperature to form a transparent and uniform solution; the solution was transferred to a polytetrafluoroethylene-lined reaction kettle, and nickel foam was used as the substrate, and the substrate was immersed in the reaction kettle solution, and then placed in an oven at 90°C to react for 7 hours; after the reaction, the substrate was taken out, washed and dried, and annealed in a tube furnace at 300°C to obtain Co 3 o 4 Nano stave.

[0024] 2 Weigh 3,4-ethylenedioxythiophene monomer (EDOT), sodium dodecyl sulfate (SDS), concentrated sulfuric acid (H 2 SO 4 ), dissolved in deionized water, and configured as an electrodeposition electrolyte, which will grow Co 3 o 4 The substrate of the nanorod is immersed in the electrolyte as the working electrode, the platinum sheet (Pt) is used as the co...

Embodiment 2

[0026] 1 Weigh cobalt nitrate hexahydrate (Co(NO 3 )2 ·6H 2 O), ammonium chloride (NH 4 Cl) and urea (CO(NH 2 ) 2 ) was dissolved in deionized water, and stirred evenly at room temperature to form a transparent and uniform solution; the solution was transferred to a polytetrafluoroethylene-lined reaction kettle, and nickel foam was used as the substrate, and the substrate was immersed in the reaction kettle solution, and then placed in an oven at 100°C to react for 6 hours; after the reaction, the substrate was taken out, washed and dried, and annealed in a tube furnace at 400°C to obtain Co 3 o 4 Nano stave.

[0027] 2 Weigh 3,4-ethylenedioxythiophene monomer (EDOT), sodium dodecyl sulfate (SDS), concentrated sulfuric acid (H 2 SO 4 ), dissolved in deionized water, and configured as an electrodeposition electrolyte, which will grow Co 3 o 4 The substrate of the nanorod is immersed in the electrolyte as the working electrode, the platinum sheet (Pt) is used as the cou...

Embodiment 3

[0029] 1 Weigh cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O), ammonium chloride (NH 4 Cl) and urea (CO(NH 2 ) 2 ) was dissolved in deionized water, and stirred evenly at room temperature to form a transparent and uniform solution; the solution was transferred to a polytetrafluoroethylene-lined reaction kettle, and nickel foam was used as the substrate, and the substrate was immersed in the reaction kettle solution, and then placed in an oven at 110°C for 5 hours; after the reaction, the substrate was taken out, washed and dried, and annealed in a tube furnace at 350°C to obtain Co 3 o 4 Nano stave.

[0030] 2 Weigh 3,4-ethylenedioxythiophene monomer (EDOT), sodium dodecyl sulfate (SDS), concentrated sulfuric acid (H 2 SO 4 ), dissolved in deionized water, and configured as an electrodeposition electrolyte, which will grow Co 3 o 4 The substrate of the nanorod is immersed in the electrolyte as the working electrode, the platinum sheet (Pt) is used as the counter el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com