A self-supporting diamond-like nano-film preparation device and film preparation method

A nano-film, self-supporting technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems that affect the production of support film, the thickness quality affects the success of stripping and salvage, and achieve high separation The effects of chemical conversion rate, high deposition rate, and high ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

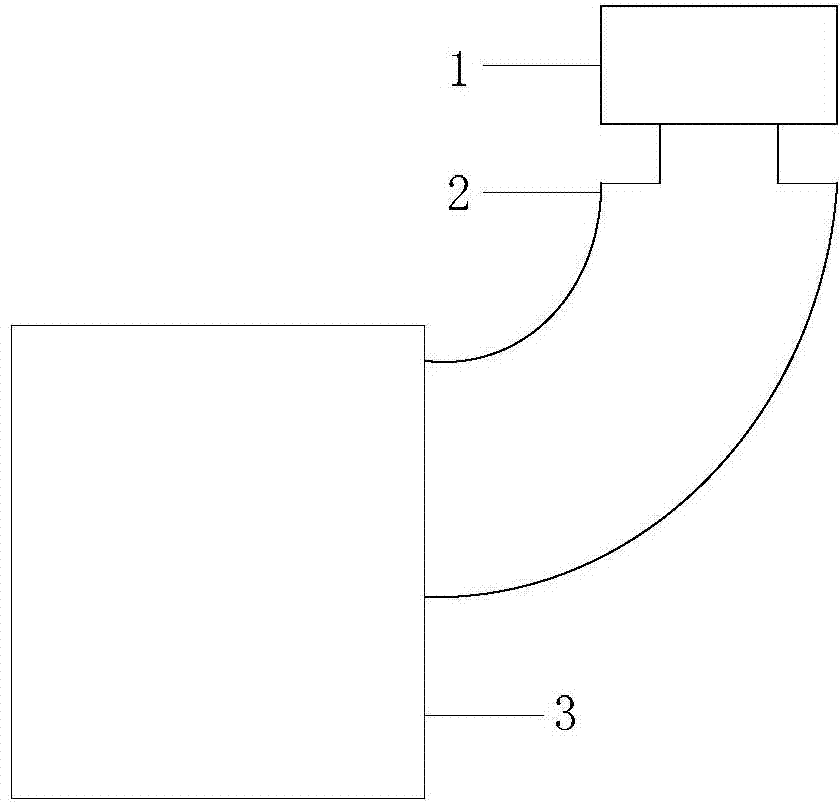

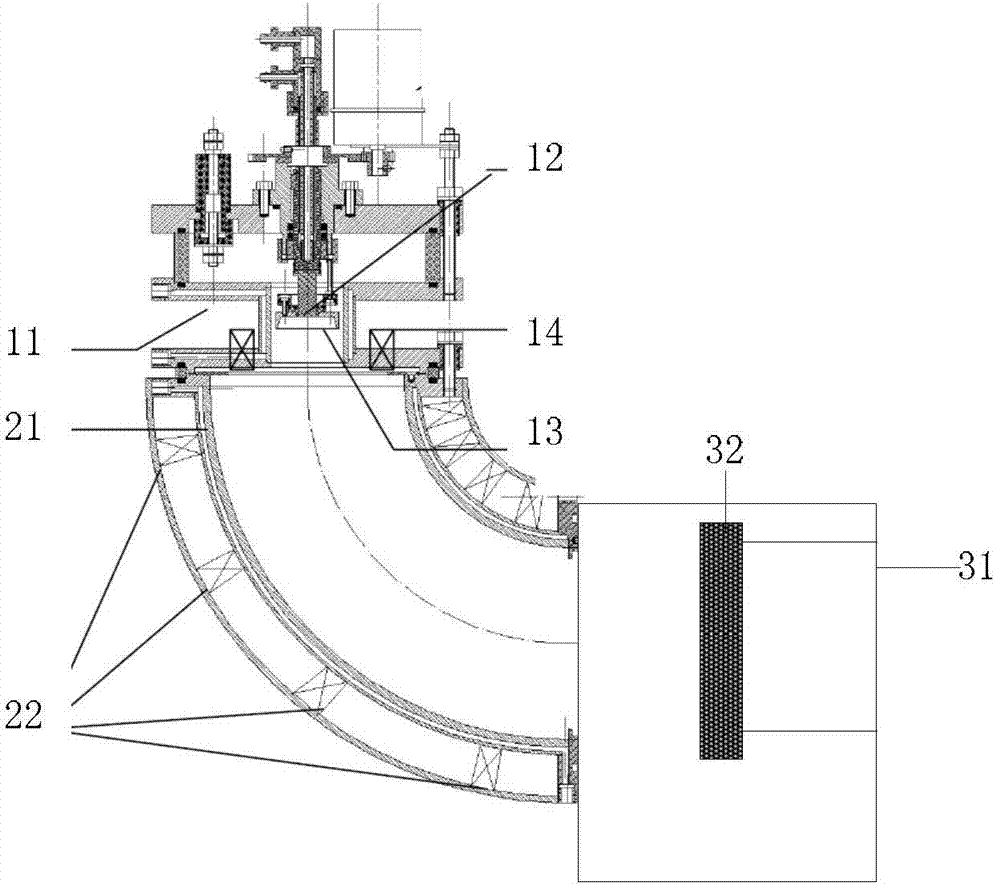

[0042] like figure 1 Shown: the self-supporting diamond-like nano-film preparation device of the present invention comprises: electrode system 1, diverter bend pipe 2 and deposition chamber 3; The deposition chamber 3 is connected, and the three constitute a vacuum chamber. like figure 2 As shown, the electrode system 1 includes a trigger electrode 13 and an arc coil 14 between the cathode 12 and the anode 11; the diverter bend 2 includes a bend 21 and a diverter coil 22 wound outside the bend, on the diverter coil 22 There is current, the inlet of the elbow 21 is connected to the cathode 12 of the motor system, and the outlet is connected to the deposition chamber 3; the bending angle of the diverter elbow 2 is 90 degrees; the deposition chamber 3 is provided with a substrate table 32, which has been plated The substrate with the release ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com