A kind of plasma deposition device and deposition method

A plasma and deposition device technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problem of high power supply voltage, achieve the effects of small dielectric loss, uniform discharge and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

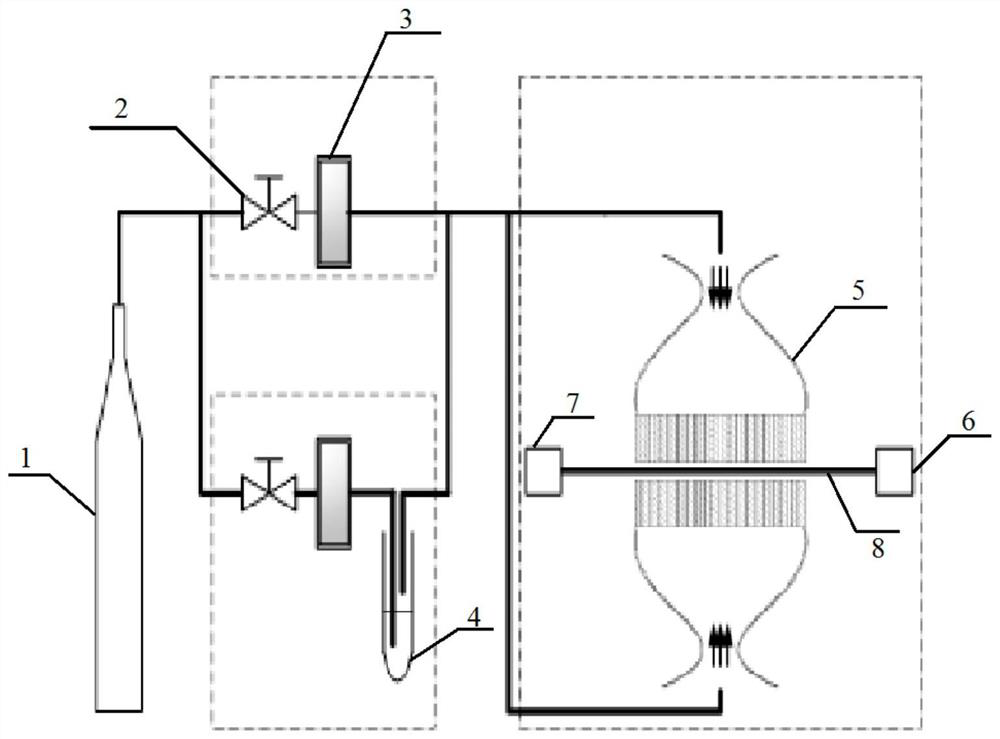

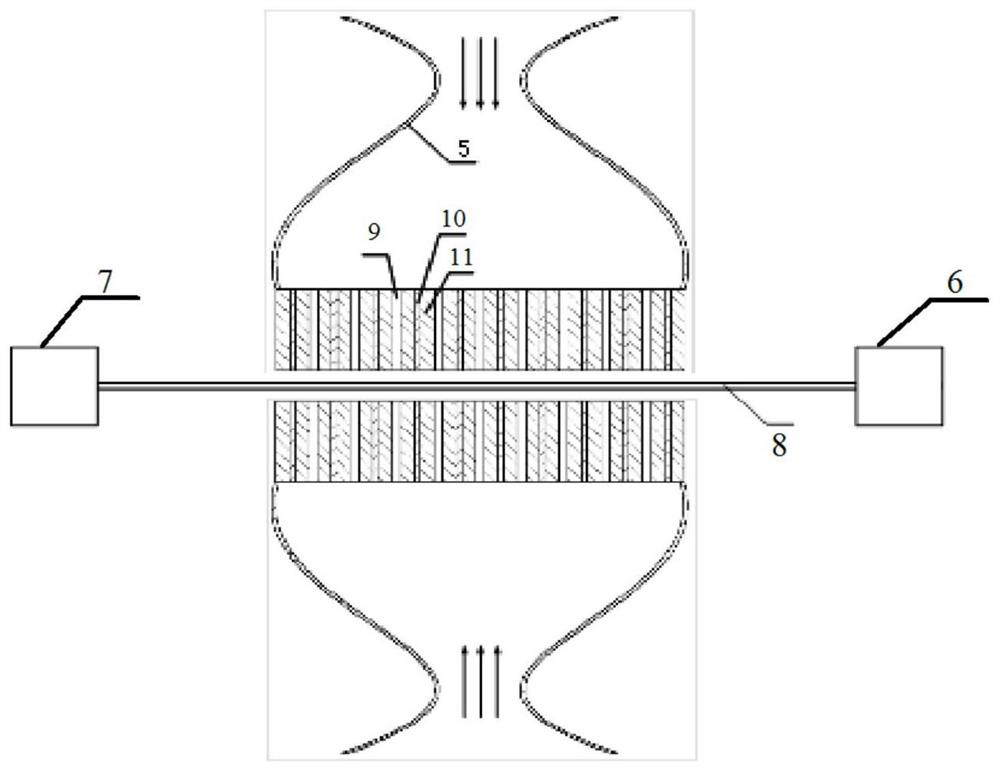

[0054] The present invention provides a plasma deposition device, such as figure 1 , figure 2 , image 3 and Figure 4 shown, including,

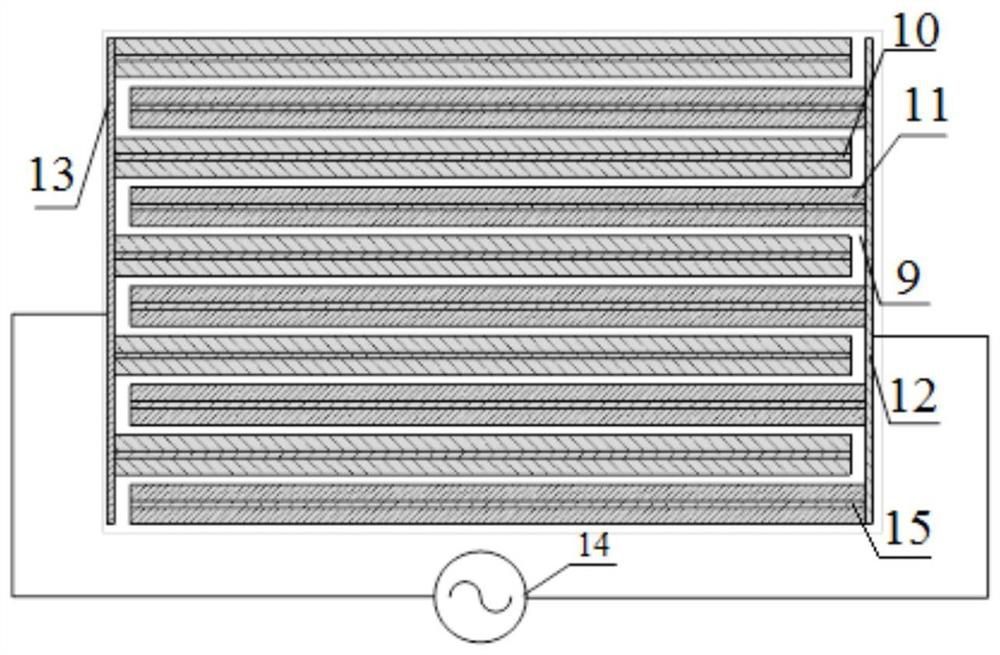

[0055] At least one plasma exciter includes several electrodes, air inlet cover 5, and blocking medium 11; said several electrodes include electrodes 15 connected with high-voltage electrode plates and electrodes 10 connected with ground electrode plates, and said electrodes connected with high-voltage electrode plates The electrode 15 and the electrode 10 connected to the ground electrode plate are alternately arranged. For example, the electrode can be linear, and as a deformable embodiment, the electrode is plate-shaped; the outer surface of the electrode has several protrusions, and The outside is covered with a barrier medium 11, and the barrier medium is a round tube. As a deformable embodiment, the barrier medium is layered; there is a gap between adjacent electrodes coated with the barrier medium, specifically, the gap is an air...

Embodiment 2

[0066] The present invention provides a plasma deposition method, specifically comprising:

[0067] Set the power supply voltage to 10kV, the frequency to 20kHz, the film output temperature to 210°C, and the film moving speed to 1cm / s. The gas is divided into two paths, the gas flow into the precursor is 3slm, and the gas flow in the other path is 300sccm , the precursor is the polyaddition product of ammonia borane (BHNH) n ; wherein, the protrusion is obtained by atomizing iodine in a molten state, and then condensed on the electrode, the increase rate of the protrusion height is 0.1mm / s, the deposition time is 0.5s, and the protrusion height is 0.05mm ;

[0068] Select a polypropylene film with a thickness of 0.5×50m and a thickness of 12 μm, and put it into the film output device. The gas cylinder is an argon gas bottle, and the gas is fed into it to control its flow rate. Turn on the power, and obtain a modified film after plasma treatment for 400 minutes.

[0069] It w...

Embodiment 3

[0076] The present invention provides a plasma deposition method, specifically comprising:

[0077] Set the power supply voltage to 9kV, the frequency to 18kHz, the film output temperature to 200°C, and the film moving speed to 1cm / s. The gas is divided into two paths. The gas flow into the precursor is 4.0slm, and the gas flow in the other path is 300sccm, the precursor solution is the polyaddition product of ammonia borane (BHNH) n ; Wherein, the protrusion is obtained by atomizing iodine in a molten state, and then condensed on the electrode, the increase rate of the protrusion height is 0.5mm / s, the deposition time is 1s, and the protrusion height is 0.5mm;

[0078] Select a polyimide film with a thickness of 0.5×50m and a thickness of 12 μm, and put it into the film output device. The gas cylinder is an argon gas cylinder, and the gas is fed to control its flow rate. Turn on the power, and obtain a modified film after plasma treatment for 380 minutes.

[0079] It was obs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com