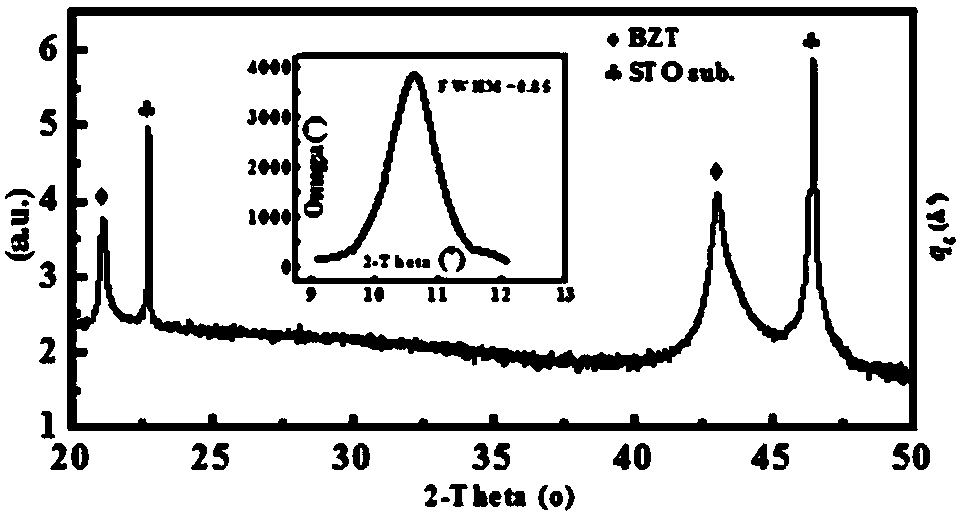

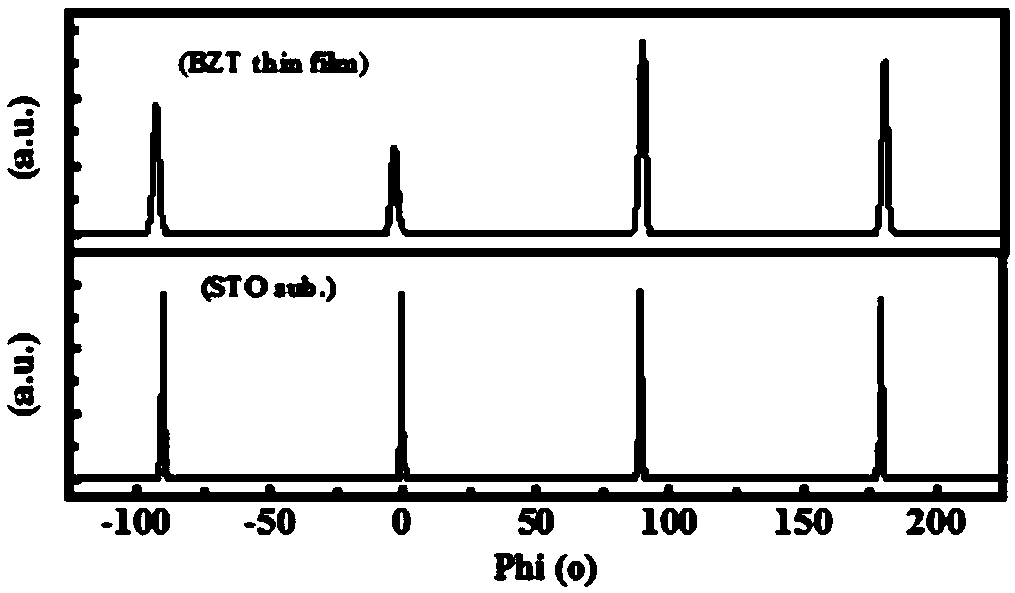

High-reliability BZT lead-free epitaxial single-crystal energy storage thin film and preparation method thereof

A reliable, single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of rare research and rare reports, and achieve smooth film surface, uniform grain size, and degree of epitaxy. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of BaZr 0.2 Ti 0.8 o 3 Ceramic target: according to BaZr 0.2 Ti 0.8 o 3 The stoichiometric ratio weighs 4-5N level BaCO 3 High purity powder, ZrO 2 High purity powder and TiO 2 High-purity powder, after the three are mixed, the mixture is sequentially subjected to ball milling, pre-sintering, secondary ball milling, granulation, molding and sintering processes to obtain flaky BaZr 0.2 Ti 0.8 o 3 Ceramic target. The process parameters of ball milling and secondary ball milling are the same, specifically: the mass ratio of ball stone, mixture and alcohol is 2:1:1, the ball milling speed is 400r / min, and the ball milling time is 6h; the pre-sintering temperature is 900℃, pre-sintering The sintering time is 4h; a tablet press is used for molding, the pressure during the molding process is 40Mpa, and the holding time is 5min; the sintering temperature in the sintering process is 1050°C, and the sintering time is 4h.

[0053] (2) Clean substrate: Co...

Embodiment 2

[0059] (1) Preparation of BaZr 0.2 Ti 0.8 o 3 Ceramic target: according to BaZr 0.2 Ti 0.8 o 3 The stoichiometric ratio weighs 4-5N level BaCO 3 High purity powder, ZrO 2 High purity powder and TiO 2 High-purity powder, after the three are mixed, the mixture is sequentially subjected to ball milling, pre-sintering, secondary ball milling, granulation, molding and sintering processes to obtain flaky BaZr 0.2 Ti 0.8 o 3 Ceramic target. The process parameters of ball milling and secondary ball milling are the same, specifically: the mass ratio of ball stone, mixture and alcohol is 2:1:1, the ball milling speed is 400r / min, and the ball milling time is 6h; the pre-sintering temperature is 900℃, pre-sintering The sintering time is 4h; a tablet press is used for molding, the pressure during the molding process is 40Mpa, and the holding time is 5min; the sintering temperature in the sintering process is 1050°C, and the sintering time is 4h.

[0060] (2) Clean substrate: Co...

Embodiment 3

[0066] (1) Preparation of BaZr 0.2 Ti 0.8 o 3 Ceramic target: according to BaZr 0.2 Ti 0.8 o 3 The stoichiometric ratio weighs 4-5N level BaCO 3 High purity powder, ZrO 2 High purity powder and TiO 2 High-purity powder, after the three are mixed, the mixture is sequentially subjected to ball milling, pre-sintering, secondary ball milling, granulation, molding and sintering processes to obtain flaky BaZr 0.2 Ti 0.8 o 3 Ceramic target. The process parameters of ball milling and secondary ball milling are the same, specifically: the mass ratio of ball stone, mixture and alcohol is 2:1:1, the ball milling speed is 400r / min, and the ball milling time is 6h; the pre-sintering temperature is 900℃, pre-sintering The sintering time is 4h; a tablet press is used for molding, the pressure during the molding process is 40Mpa, and the holding time is 5min; the sintering temperature in the sintering process is 1050°C, and the sintering time is 4h.

[0067] (2) Clean substrate: Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com