Three-dimensional warp-knitted spacer fabric reinforcing special-shape foam material and preparing method thereof

A warp-knitted spacer fabric and foam material technology is applied in the field of foam reinforcement materials to achieve the effects of reducing molding time, strong designability and reducing cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Selection of raw materials: The three-dimensional spacer fabric is woven from PET fibers with a thickness of 20mm, and the foaming material is polyurethane foam. Polyurethane foaming raw materials are divided into A component and B component; A component includes polyether polyol, foaming agent (n-pentane), foam stabilizer (organic silicon foam stabilizer), catalyst (triethylenediamine) , water and chain extender (ethylenediamine); B component is polyisocyanate. The ratio of component A to component B is calculated by mass ratio.

[0035] Component A: polyether polyol 100, n-pentane 3, silicone oil foam stabilizer 2, triethylenediamine 1.2, water 0.3, chain extender (ethylenediamine);

[0036] B component: Polyisocyanate 150.

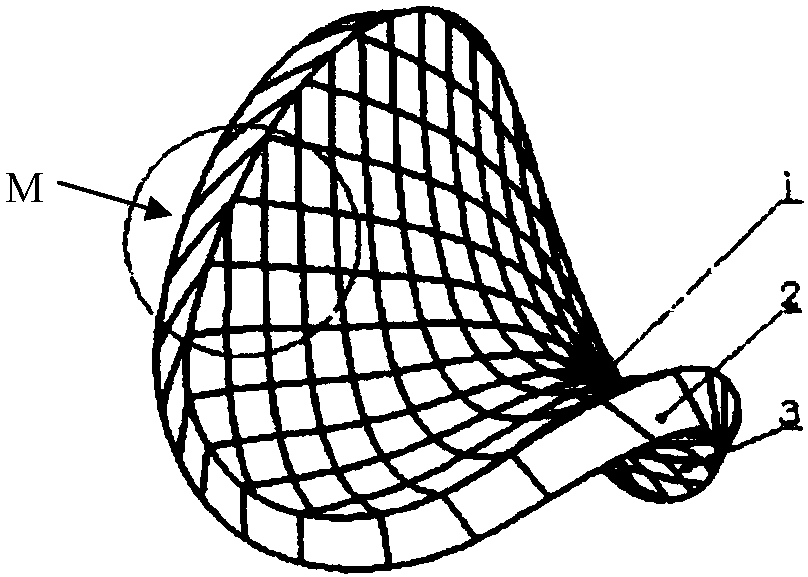

[0037] The schematic diagram of the special-shaped structure (hyperboloid) of the three-dimensional warp-knitted spacer fabric reinforced special-shaped foam material described in Embodiment 1 of the present invention is as follows figure ...

Embodiment 2

[0044](l) Selection of raw materials: the three-dimensional spacer fabric is woven from glass fiber, with a thickness of 30mm. Polyurethane foam raw materials are divided into A component and B component. A component includes polyether polyol, foaming agent (n-pentane), foam stabilizer (silicone oil foam stabilizer), catalyst (triethylenediamine), Water, chain extender (ethylenediamine); B component is polyisocyanate. The distribution ratio of A component and B group is calculated by mass ratio.

[0045] Component A: polyether polyol 100, pentane 6, silicone oil foam stabilizer 4, triethylenediamine 2.4, water 0.5, chain extender (ethylenediamine) 1.5.

[0046] B component: Polyisocyanate 150.

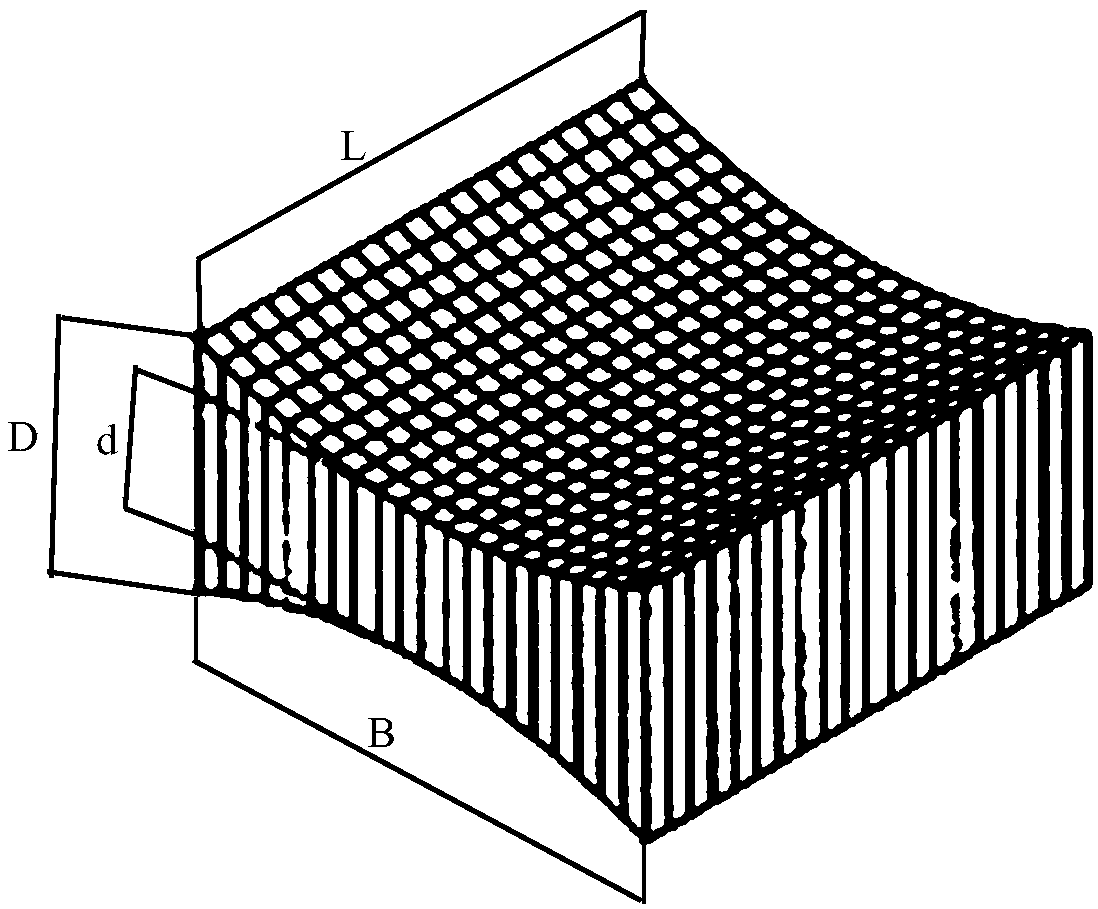

[0047] (2) Cut the three-dimensional spacer fabric to a good size, change the shape in the mold, and form such as image 3 The I-shaped cross-section structure is shown, and the shape is fixed. The upper and lower arcs of the formed I-shaped section are part of a circle with a radi...

Embodiment 3

[0053] (1) Selection of raw materials: The three-dimensional spacer fabric is woven from mixed fibers of glass fiber and PET fiber, with a thickness of 15mm, and the foaming material is phenolic foam. The main material is phenolic resin, the foaming agent is dichloroethane: n-pentane = 1:10 compound foaming agent, the surfactant is Tween-80, and the curing agent is benzenesulfonic acid. The shape of design foam material is hemispherical, and each component of raw material comprises as follows by weight:

[0054] 100 parts of phenolic resin, 8 parts of compound foaming agent, 6 parts of Tween-80, 10 parts of benzenesulfonic acid.

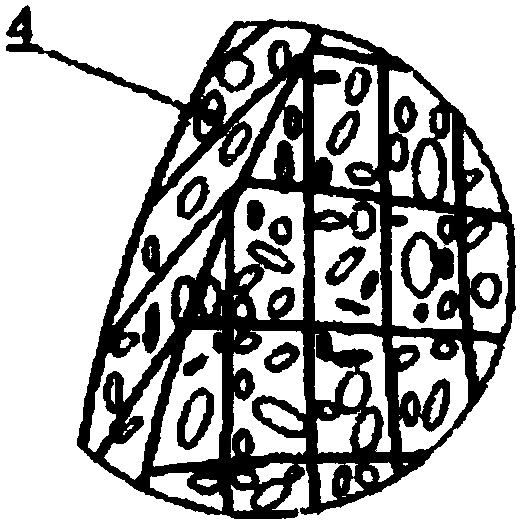

[0055] (2) Cutting the three-dimensional spacer fabric with the three-dimensional spacer fabric, changing the shape in the mold, forming such as Figure 4 Hemisphere as shown, and fix the shape. Hemispherical shell thickness C=150mm, outer diameter R=200mm.

[0056] (3) Mix the phenolic resin, compound foaming agent and Tween-80 according to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com