Method for preparing SiCp enhanced AZ91D composite material blank

A composite material and billet technology is applied in the field of preparation of SiCp reinforced AZ91D composite material billets to achieve the effects of excellent and reliable billet quality, stable and efficient process, and easy large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

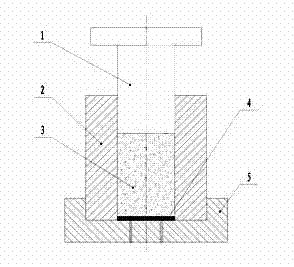

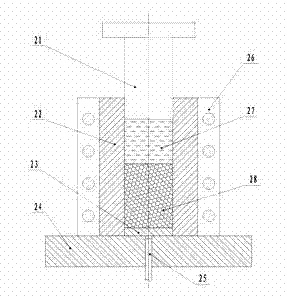

Image

Examples

Embodiment

[0047] Embodiment, the present embodiment uses SiC that the volume fraction is 50% p (Particle size 5μm) reinforced AZ91D composite material blank (diameter Φ60mm) as the object, follow the steps below:

[0048] First, prepare the aluminum phosphate high temperature binder.

[0049] Specifically include the following steps:

[0050] The first step is to weigh the powdered aluminum hydroxide Al(OH) according to the atomic ratio of Al and P: 1:23 3 And 85% concentration of industrial phosphoric acid (H 3 PO 4 ), mixed into a suspension in a mixing vessel;

[0051] In the second step, heat the suspension to 150°C and keep it warm, stirring while heating until the Al(OH) 3 The powder is all dissolved to obtain aluminum phosphate (Al(PO 3 ) 3 ) solution;

[0052] The third step is to weigh and mix the aluminum phosphate solution and water at a volume ratio of 1:15 to obtain an aluminum phosphate binder with high-temperature bonding effect.

[0053] Next, wet molding is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com