Method for preparing hot pressed balls of iron ore concentrate and powdered coal

A technology for iron ore concentrate powder and iron ore concentrate, which is applied in the field of iron and steel smelting, can solve the problems of increasing slag amount, restricting the mass use of cold consolidation pellets, reducing the compressive strength of pellets, etc., and achieves broad application prospects and excellent melting The effect of dripping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

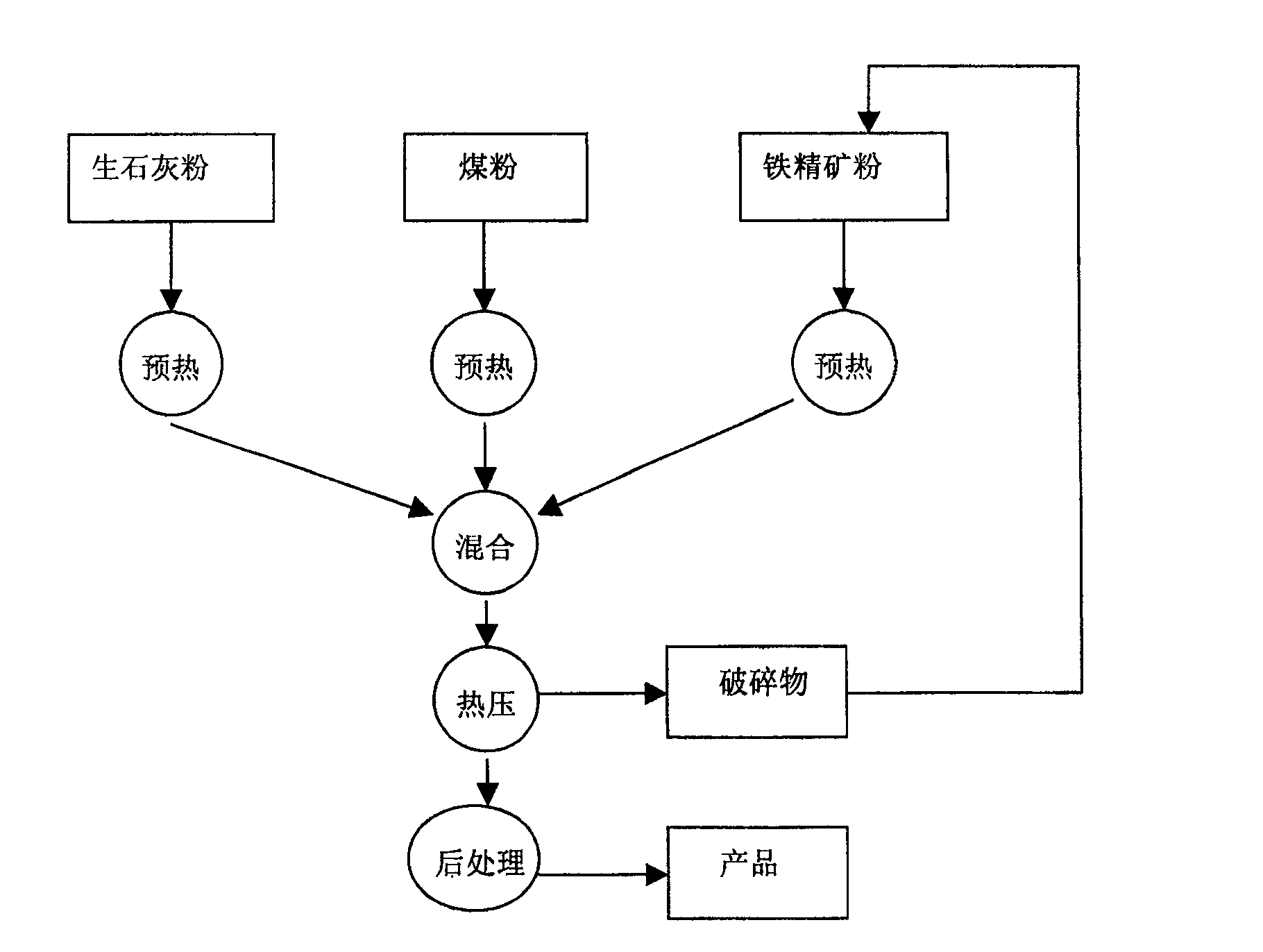

Method used

Image

Examples

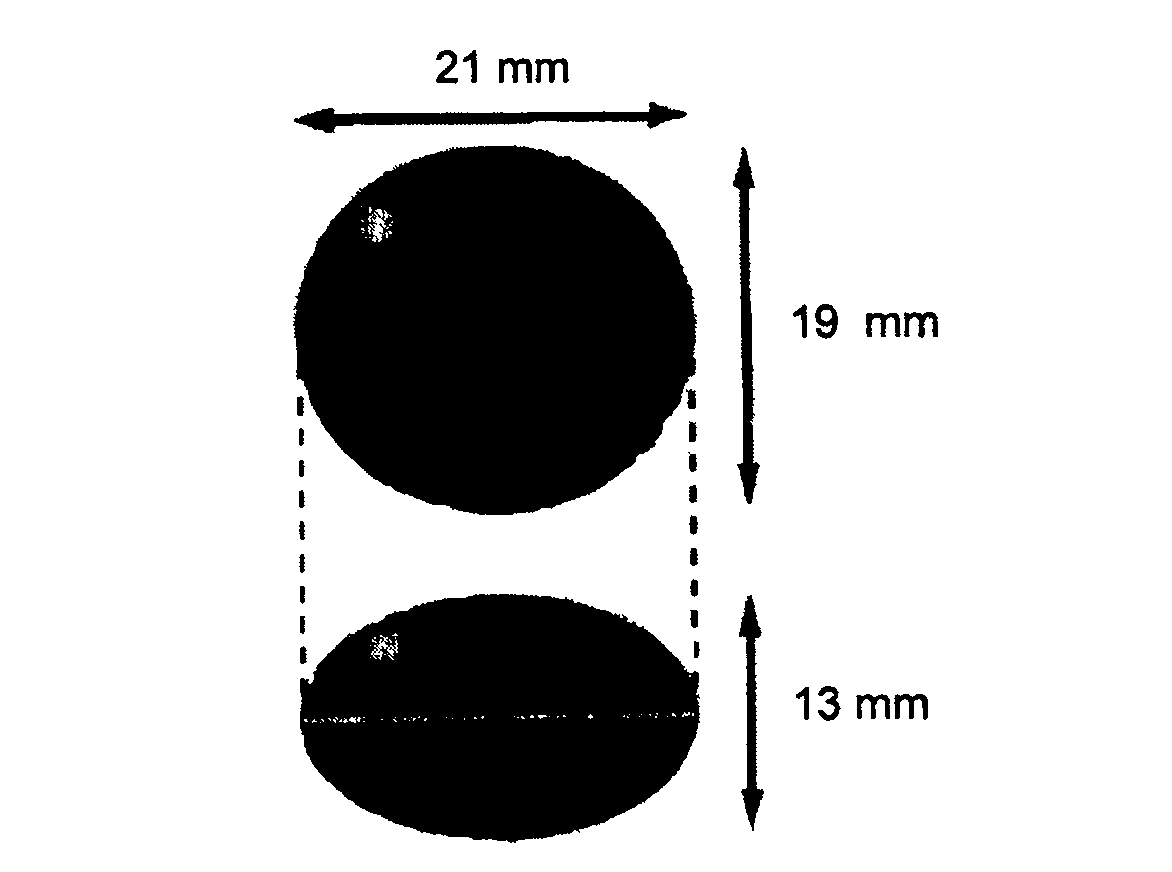

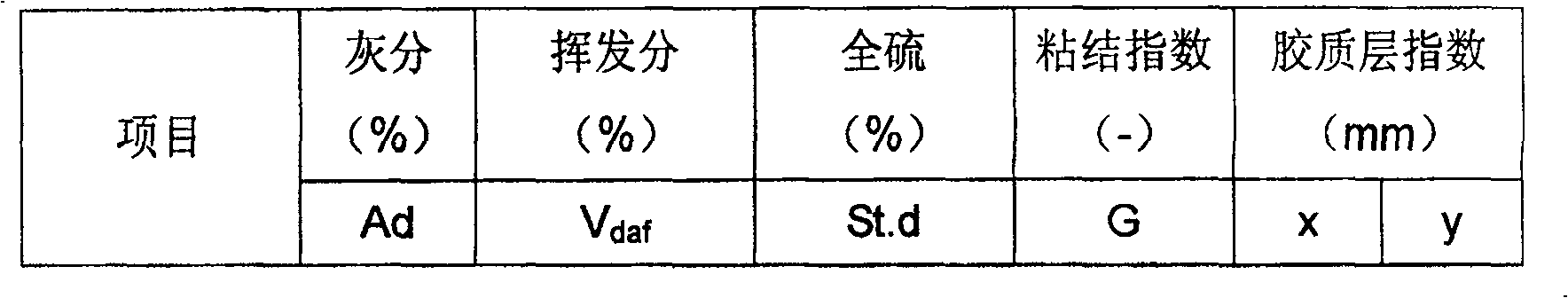

Embodiment 1

[0033] Iron concentrate coal powder hot-pressed briquettes are formed by hot-pressing iron concentrate powder, coal powder and flux. The particle size of pulverized coal is 120 mesh to 200 mesh, which is 100%, of which -200 mesh is 33%; the particle size of iron concentrate powder is the particle size after beneficiation, and -200 mesh is greater than 60%; the flux is quicklime (CaO) powder, particle size -200 Mesh>50%. According to weight percentage, iron concentrate powder 65.2%, coal powder 27.9% and quicklime powder 6.9% are proportioned, coal powder is preheated to 150°C, iron concentrate powder is preheated to 700°C, quicklime powder is preheated to 150°C. Then, the above-mentioned preheated iron concentrate powder, coal powder and flux were mixed and stirred for 18 minutes, and the mixture of the fully mixed iron concentrate powder, coal powder and flux was hot-pressed with a double-roller hot press, and heated The pressing temperature is 450°C and the pressure is 35M...

Embodiment 2

[0040] Iron concentrate coal powder hot-pressed briquettes are formed by hot-pressing iron concentrate powder, coal powder and flux. Coal powder particle size between 120 mesh and 200 mesh is 100%, of which -200 mesh is 35%; the particle size of iron concentrate powder is the particle size after beneficiation, and -200 mesh is greater than 60%; the flux is quicklime (CaO) powder, particle size -200 Mesh>50%. Preheat the coal powder to 200°C, preheat the iron concentrate powder to 750°C, and preheat the quicklime powder to 200 ℃. Then, mix and stir the above-mentioned preheated iron ore concentrate powder, coal powder and flux for 20 minutes, and heat press the mixture of fully mixed iron ore concentrate powder, coal powder and flux with a double-roller hot press, heat The pressing temperature is 500°C and the pressure is 25MPa. The crushed material of the hot-pressed agglomerate is returned to the raw material part of the iron ore powder, and enters the preheating step toge...

Embodiment 3

[0042] Iron concentrate coal powder hot-pressed briquettes are formed by hot-pressing iron concentrate powder, coal powder and flux. Coal powder particle size between 120 mesh and 200 mesh is 100%, of which -200 mesh is 30%; the particle size of iron concentrate powder is the particle size after beneficiation, and -200 mesh is greater than 60%; the flux is quicklime (CaO) powder, particle size -200 Mesh>50%. Preheat the coal powder to 100°C, the iron concentrate powder to 600°C, and the quicklime powder to 100% by weight. ℃. Then, mix and stir the above-mentioned preheated iron concentrate powder, coal powder, and flux for 15 minutes, and use a double-roller hot press to heat press the mixture of the fully mixed iron concentrate powder, coal powder, and flux. The pressing temperature is 400°C and the pressure is 45MPa. The crushed material of the hot-pressed agglomerate is returned to the raw material part of the iron ore powder, and enters the preheating step together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com