Ultra-high power limiter mmic and its preparation method based on bonding transfer

A super-power, limiter technology, applied in the field of super-power limiter MMIC and preparation based on bonding transfer, to achieve the effect of avoiding integration, excellent performance and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing an ultra-high power limiter MMIC based on bonding transfer, comprising the following steps:

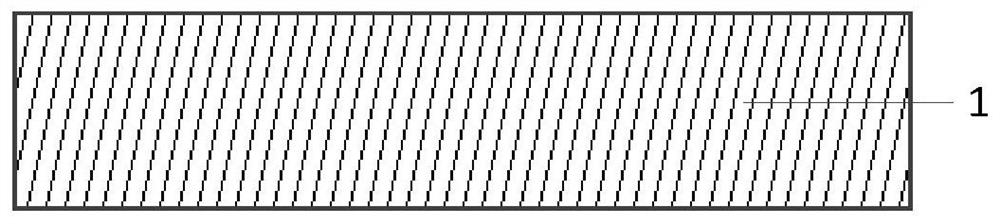

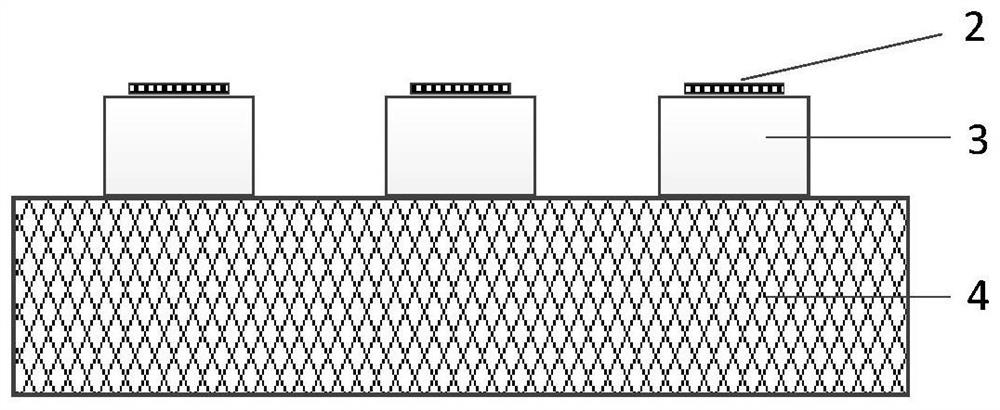

[0042] ① Prepare PIN mesa structure and upper electrode 2 on the front side of Si wafer 4: prepare PIN mesa structure on Si wafer 4, the mesa structure is Si PIN die 3, and the height of PIN mesa is from 1um-50um according to design requirements, And wash it with diluted hydrochloric acid HCl, acetone, alcohol and deionized water, put it into a dryer for drying, such as figure 2 shown.

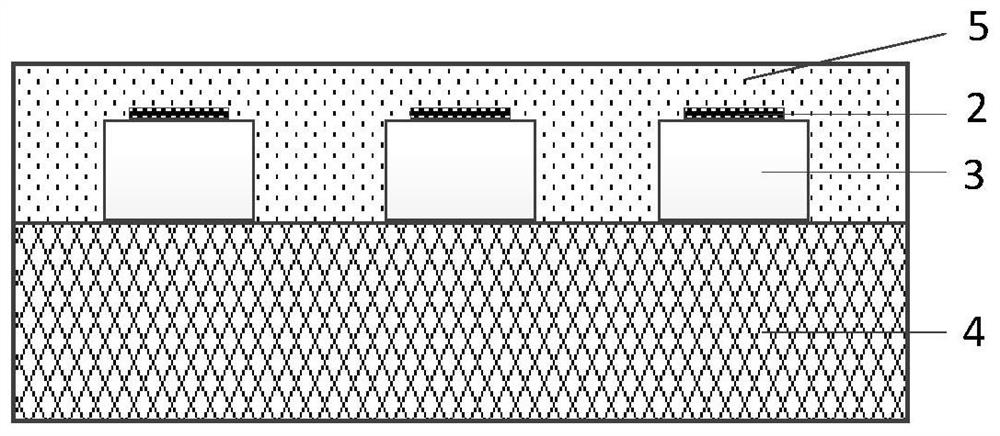

[0043] ② Spin-coating the adhesive 5 on the front side of the Si wafer 4: drop-coating the adhesive 5 on the front side of the Si wafer including the PIN mesa structure, the adhesive 5 selected is wax, BCB or photoresist. Set the spin coating speed to 1000-5000 rpm according to the required thickness, and the spin coating time is 30 seconds to 1 minute. Put the Si PIN tube wafer coated with adhesive 5 face up on the hot plate for pre-baking Bake with the hot plate temp...

Embodiment

[0055] A method for preparing an ultra-high power limiter MMIC based on bonding transfer, comprising the following steps:

[0056] ① Prepare the PIN mesa structure on the Si wafer, the PIN mesa height is 5um, prepare the PIN upper electrode, clean it with diluted hydrochloric acid HCl, acetone, alcohol and deionized water, and put it in a dryer for drying;

[0057] ②Drop-coat an appropriate amount of high-temperature wax on the front of the Si wafer with the PIN structure, set the spin-coating speed to 2000 rpm, the acceleration to 2000 rpm, and the spin-coating time to 50s; place the Si PIN coated with high-temperature wax Put the tube disc face up on the hot plate for pre-baking, the temperature of the hot plate is set at 110 ° C, and the time is 2 minutes;

[0058] ③Paste the front side of the Si wafer containing the PIN structure and the temporary carrier together, and perform temporary bonding with a bonding machine. The bonding temperature is set at 200°C, the bonding ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com