Strengthening and toughening heat treatment method of medium carbon manganese-vanadium low alloy steel

A heat treatment method and technology for low-alloy steel, applied in the field of heat treatment for strengthening and toughening of low-alloy steel, can solve the problems of not being able to have strength and plastic toughness at the same time, low strength and poor toughness of medium carbon manganese vanadium low alloy steel, and achieving good plasticity. , The effect of improving toughness and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

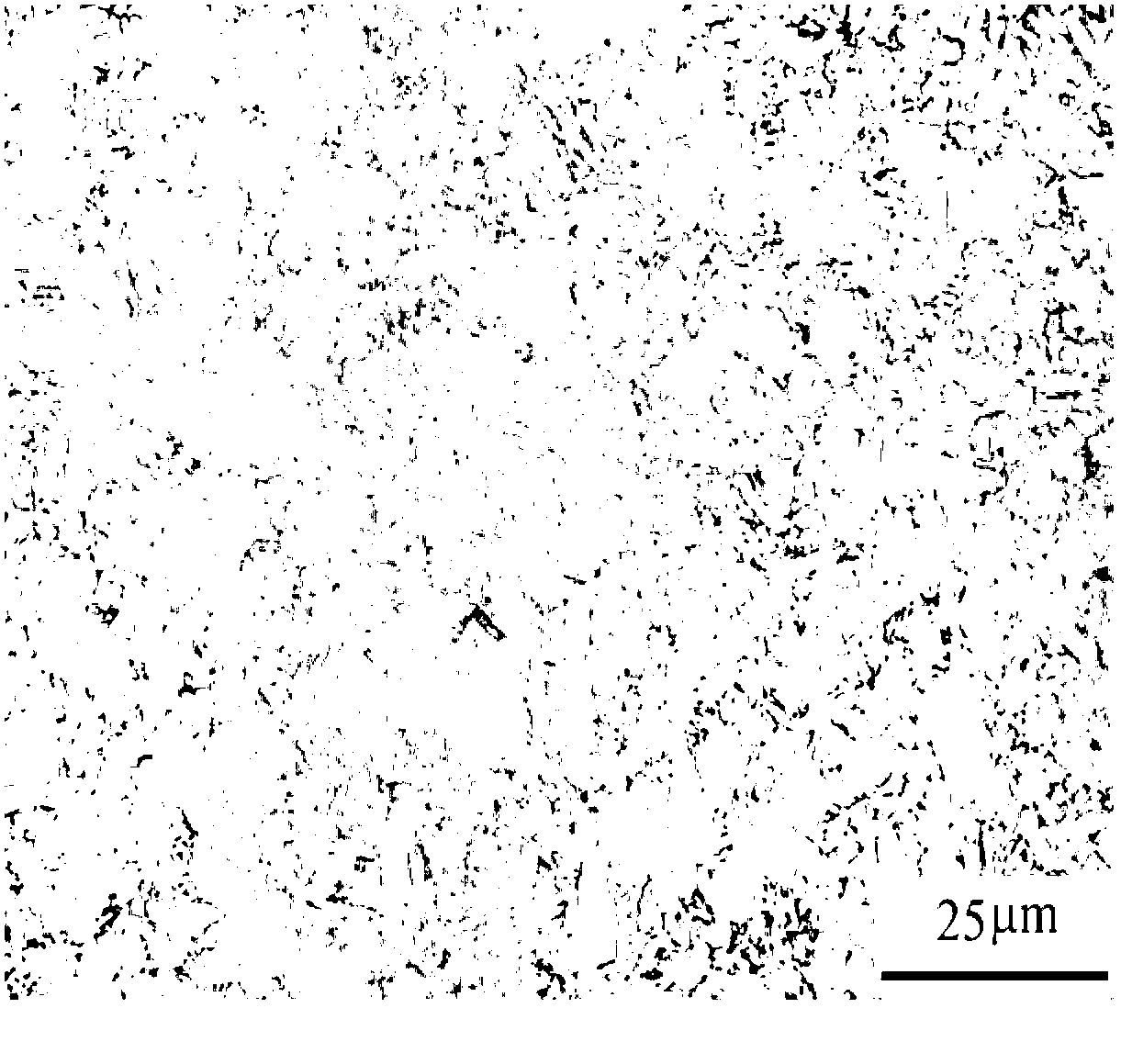

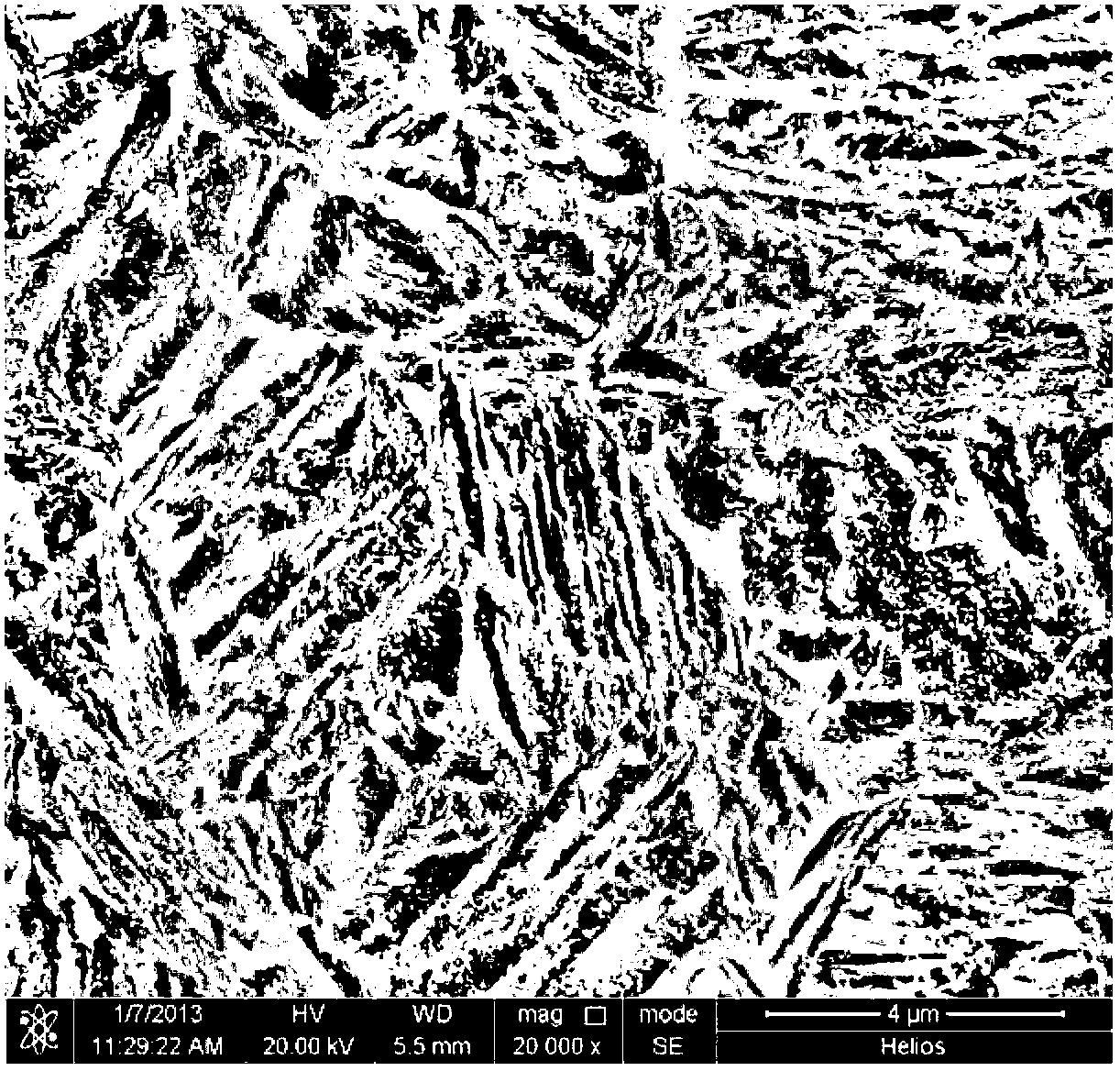

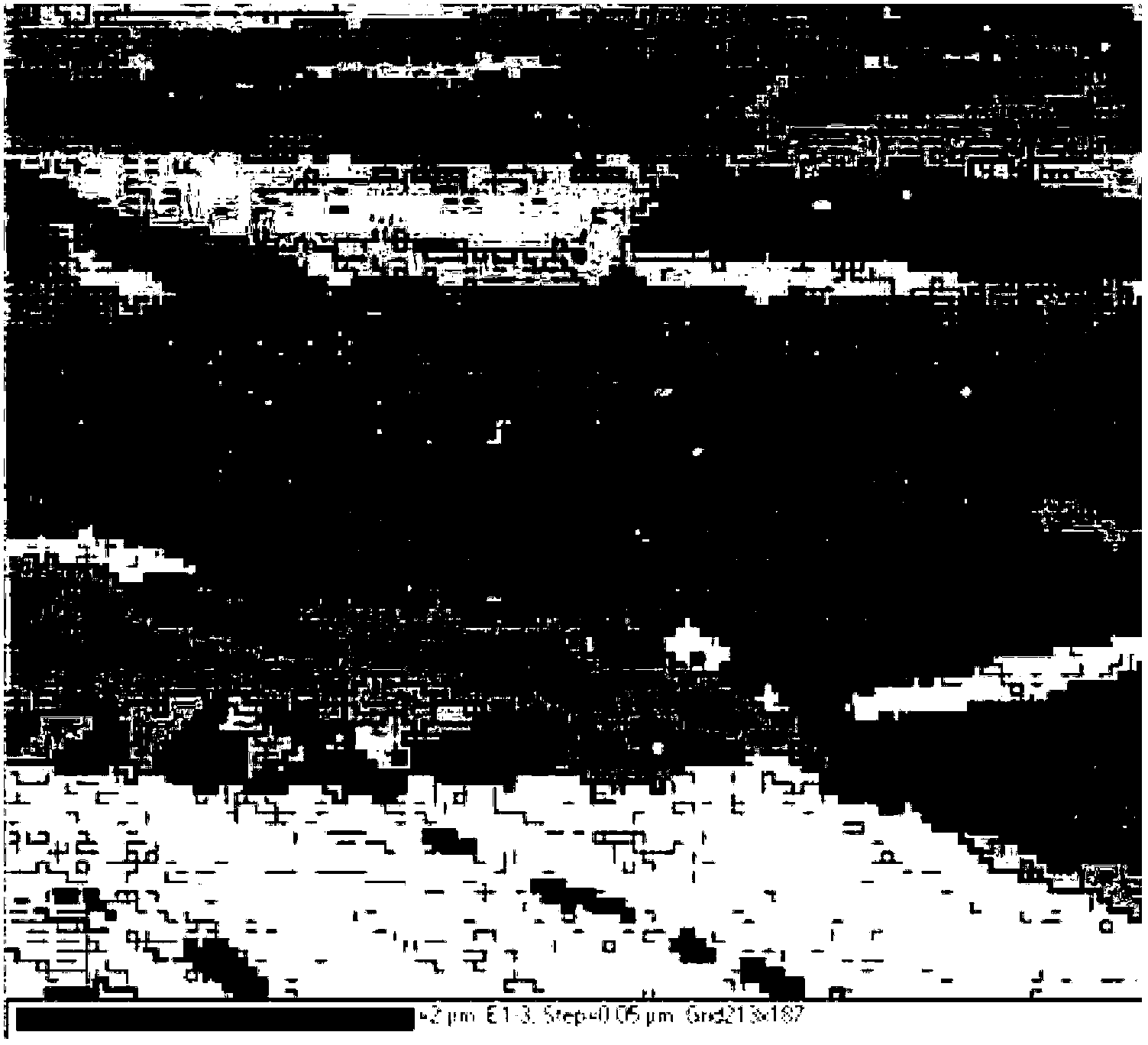

[0011] Specific implementation mode one: a kind of medium-carbon manganese vanadium low-alloy steel strengthening and toughening heat treatment method in this embodiment is carried out according to the following steps:

[0012] The medium-carbon manganese-vanadium low-alloy steel is austenitized, and then isothermally quenched in the temperature range of 100°C to 10°C below the martensitic transformation start point Ms of the medium-carbon manganese-vanadium low-alloy steel. The thickness of the carbon-manganese-vanadium low-alloy steel is calculated to be 60 s / mm, and then quenched to room temperature to complete the strengthening and toughening heat treatment of the medium-carbon manganese-vanadium low-alloy steel.

[0013] The martensitic transformation starting point Ms of the medium-carbon manganese-vanadium low-alloy steel of the present embodiment is a fixed value for the martensitic point Ms of a certain medium-carbon manganese-vanadium low-alloy steel, and those skille...

specific Embodiment approach 2

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the specific operation process of the described austenitizing treatment is as follows: the medium carbon manganese vanadium low alloy steel is placed at the temperature of A of the medium carbon manganese vanadium low alloy steel c3 Insulation under the above conditions of 30°C to 50°C, the holding time is 60s to 3600s, that is, the austenitization treatment is completed; the A c3 It is the final temperature when ferrite is completely transformed into austenite when heated. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the composition of the described medium carbon manganese vanadium low alloy steel is as follows: C content is 0.25Wt.%~0.5Wt.%, Si content is 0.15 Wt.%~0.45Wt.%, Mn content 1.15Wt.%~1.8Wt.%, V content 0.08Wt.%~0.12Wt.%, Al content 0.02Wt.%~0.04Wt.%, Nb content ≤0.05Wt.%, P content ≤0.02Wt.% and S content ≤0.02Wt.%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com