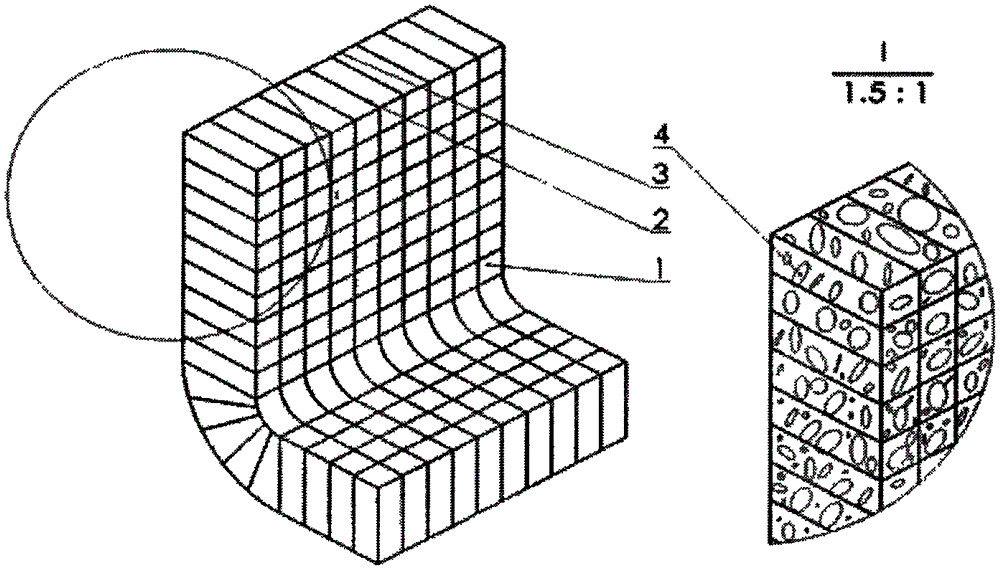

Three-dimensional spacer fabric reinforced cement-based composite material and preparation method thereof

A technology of cement-based materials and spacer fabrics, which is applied to manufacturing tools, surface layering devices, ceramic molding machines, etc., can solve the problems of low flexural strength, high brittleness, easy cracking, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Select raw materials. The three-dimensional spacer fabric is woven from PET fibers with a thickness of 20mm; the resin used is unsaturated polyester resin; the cementitious material is 42.5R Portland cement, and the admixture is naphthalene-based water reducer. The water-cement ratio is 0.54, and the mass ratio of cement to water reducer is 100:1.2.

[0030] Step 2: Put the three-dimensional spacer fabric into the mold, fix the shape in the mold, and use the resin transfer molding technology to compound the three-dimensional spacer fabric with the resin to obtain the skeleton of the three-dimensional spacer fabric composite material.

[0031] The third step: mix and stir the cement cementitious material, water and admixture in proportion, and pour it into the skeleton of the three-dimensional spacer fabric composite material obtained in the second step.

[0032] Step 4: Oscillate the mold to fully fill the three-dimensional spacer fabric with the mixed slurry. ...

Embodiment 2

[0039] Step 1: Select raw materials: the three-dimensional spacer fabric is woven from glass fiber with a thickness of 15mm; the resin used is epoxy resin; the cement-based material is foamed concrete, the cementitious material is sulphoaluminate cement, and the foaming agent is hydrogen peroxide , the admixture is a naphthalene-based water reducer and a foam stabilizer. The bulk density of the designed foam concrete is 300kg / m3, and the water-cement ratio is 0.54.

[0040] Step 2: Put the three-dimensional spacer fabric into the mold, fix the shape in the mold, and use the resin transfer molding technology to compound the three-dimensional spacer fabric with the resin to obtain the skeleton of the three-dimensional spacer fabric composite material.

[0041] Step 3: Mix and stir the cement gelling material, water, water reducing agent and foam stabilizer in proportion to form a uniform slurry; Spacer fabric composite skeleton.

[0042] Step 4: Oscillate the mold to fully fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com