Resin-based Ni-Co-Mn-In alloy composite material and preparation method thereof

A ni-co-mn-in, composite material technology, applied in the field of composite materials, can solve problems such as unobserved strain output, achieve the effects of good magnetic field induced strain, low preparation cost, and reduced stress confinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

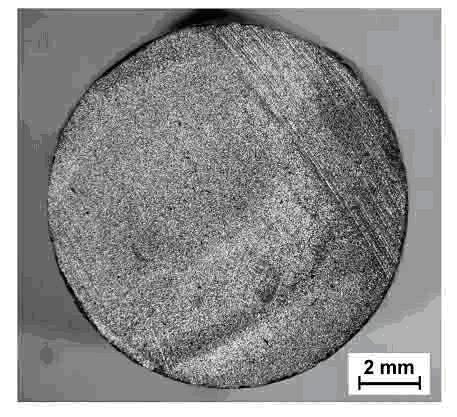

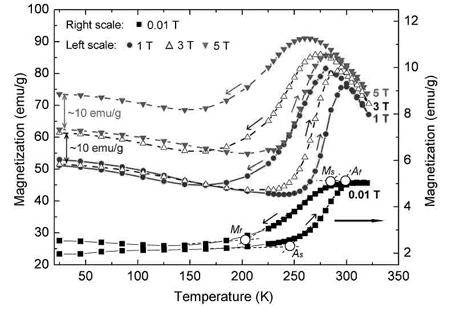

[0027] Example 1: First, the martensitic transformation point of Ni with a transformation point of 25°C was 45 Co 5 Mn 36.6 In 13.4 The alloy material is ball-milled to a particle size of 20~60 μm and then mixed with the resin evenly, so that the alloy material accounts for 25% of the volume of the composite material, and then the mixed material is stirred in a water bath at 60°C at 50 to 60 revolutions per minute. Stir and mix by hand for 20 minutes at a high speed to make the mixture slurry, then pour the slurry into the mold, put it into a vacuum drying box and vacuumize at 80 °C for 3 hours, turn off the vacuum, heat the slurry to 120 °C, and keep warm Cured for 6 hours to finally obtain resin-based Ni 45 Co 5 Mn 36.6 In 13.4 alloy. figure 1 The appearance photo of the cross-section of the resin-based Ni-Co-Mn-In alloy composite material prepared in this example is shown in the figure. As shown in the figure, the alloy particles in the composite material of this exa...

Embodiment 2

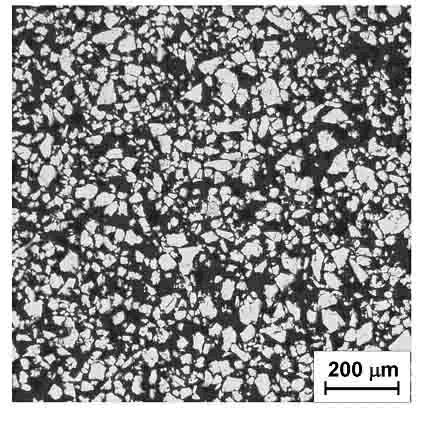

[0033] Example 2: First, the martensitic transformation point of Ni with a transformation point of 25 ° C was 45 Co 5 Mn 36.6 In 13.4 The alloy material is ball-milled to a particle size of 20-60 μm and then mixed with the resin evenly, so that the alloy material accounts for 50% of the volume of the composite material, and then the mixed material is manually mixed in a water bath at 60°C at a stirring speed of 60 rpm. Stir and mix for 40 minutes to make the mixture slurry, then pour the slurry into the mold, put it into a vacuum drying box and vacuumize at 80 °C for 5 hours, turn off the vacuum, heat the slurry to 120 °C, and heat preservation for 7 hours. hours, and finally obtain resin-based Ni 45 Co 5 Mn 36.6 In 13.4 alloy. Figure 4 The metallographic structure diagram of the resin-based Ni-Co-Mn-In alloy composite material prepared in this example.

Embodiment 3

[0034] Example 3: First, the martensitic transformation point of Ni with a transformation point of 25°C was 45 Co 5 Mn 36.6 In 13.4 The alloy material is ball-milled to a particle size of 20-60 μm and then mixed with the resin evenly, so that the alloy material accounts for 33% of the volume of the composite material, and then the mixed material is manually mixed in a water bath at 60 °C at a stirring speed of 55 revolutions per minute. Stir and mix for 30 minutes to make the mixture slurry, then pour the slurry into the mold, put it into a vacuum drying box and vacuumize at 80 ° C for 4 hours, turn off the vacuum, heat the slurry to 120 ° C, and heat preservation for 7 hours. hours, and finally obtain resin-based Ni 45 Co 5 Mn 36.6 In 13.4 alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com