Hole type multi-cavity colloid thrustor

A technology of thrusters and colloids, which is applied in the direction of machines/engines, mechanical power generated by physical force, mechanisms that generate mechanical power, etc., can solve the problem of less research units, the influence of thruster structural parameters on propeller performance, and colloidal The detailed design of the thruster has not been reported publicly, etc., to achieve the effect of easy processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The hole-type multi-cavity colloidal thruster of the present invention will be described in detail below in conjunction with the accompanying drawings.

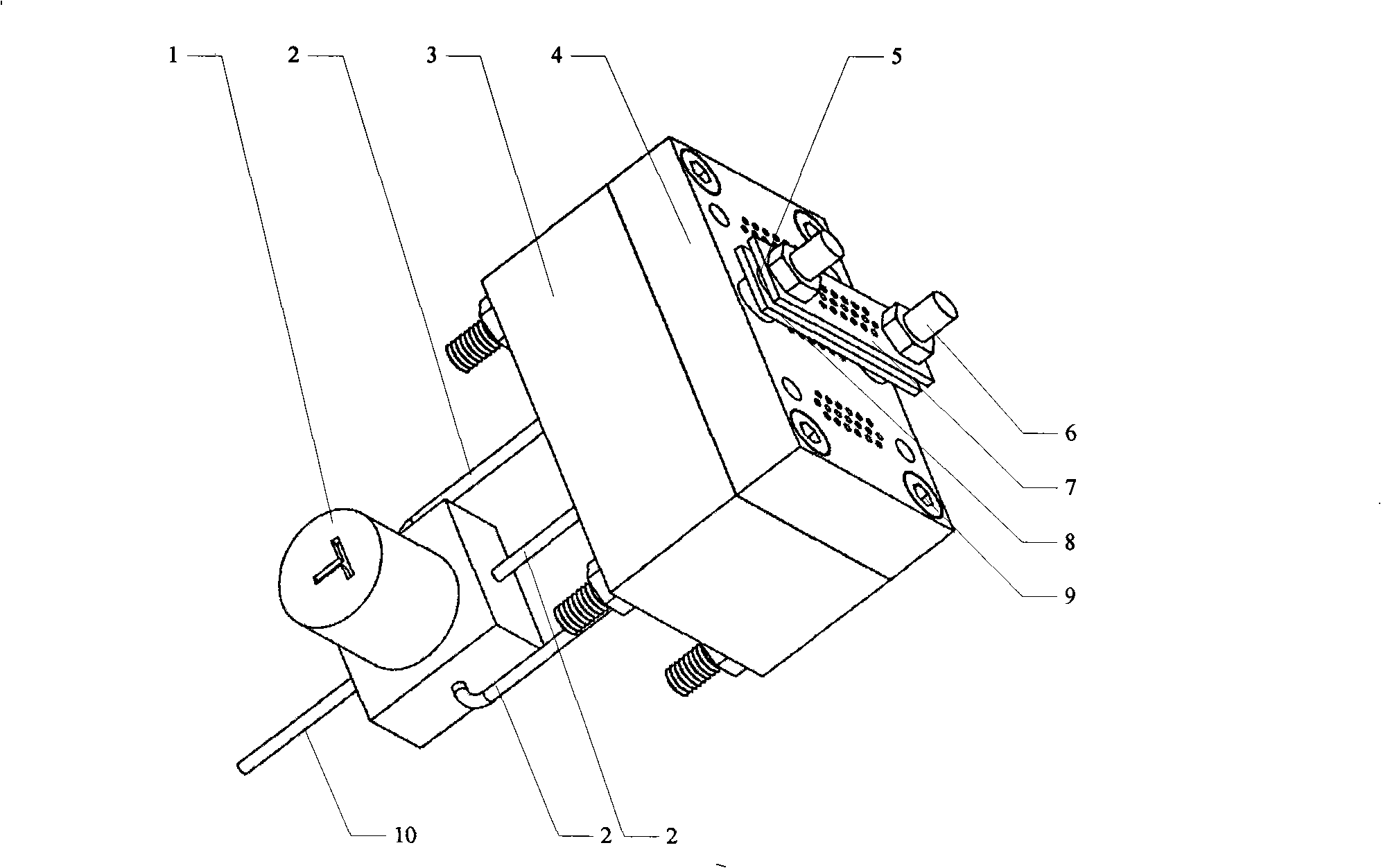

[0028] Such as figure 1 , the hole-type multi-chamber gel thruster provided by the present invention includes a multi-directional valve 1, a stainless steel capillary line 2, a storage tank 3, an insulating base 4, an insulating gasket 5, an insulating stud 6, an accelerating pole 7, and an extraction pole 8. Countersunk head screw 9. PEEK pipeline 10.

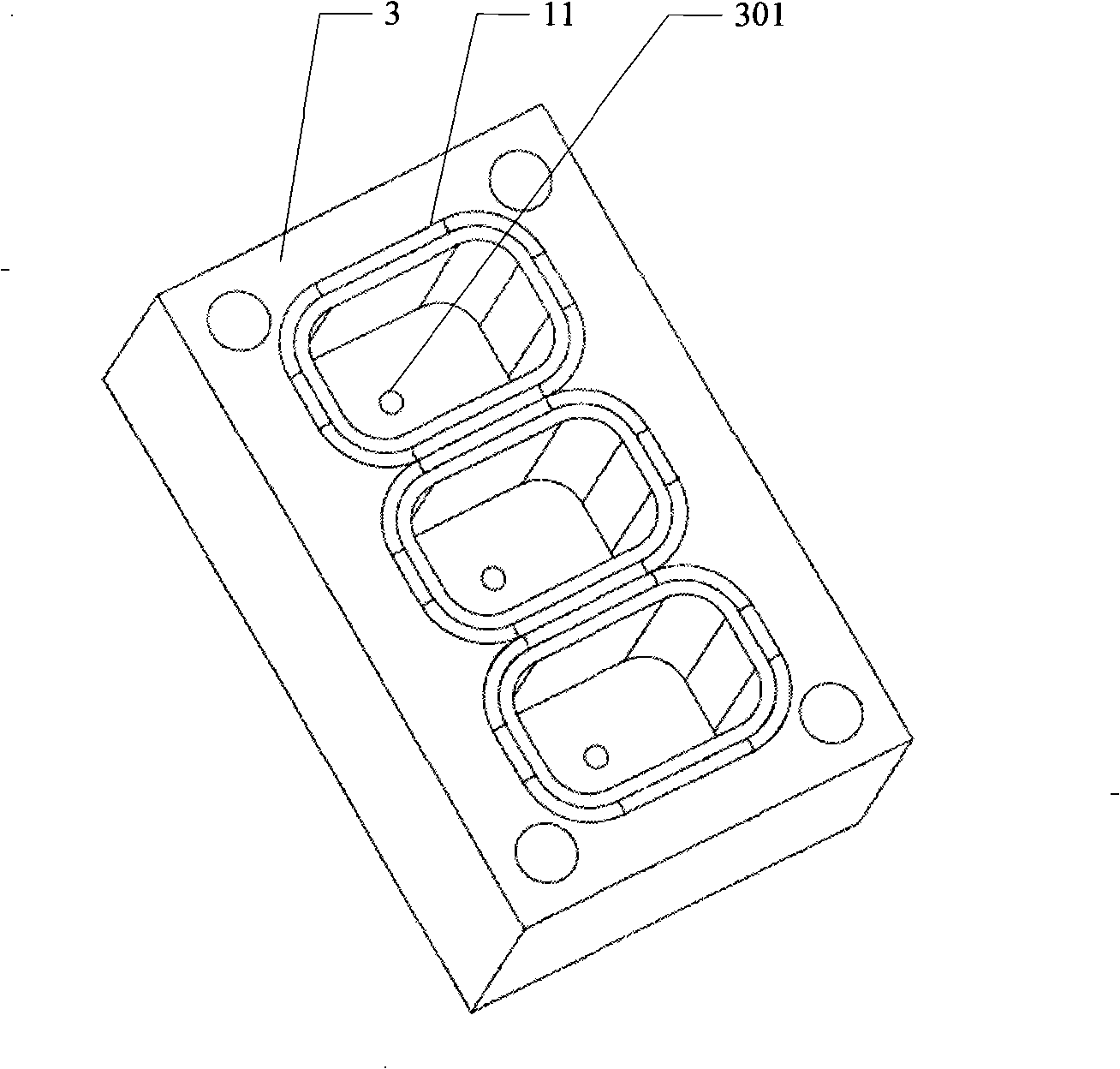

[0029] The multi-way valve 1 is connected with a stainless steel capillary line 2 and a PEEK line 10, wherein there is one PEEK line 10 for realizing single-way supply of propellant, and the stainless steel capillary line 2 has multiple lines, which are respectively connected to the multi-way Between valve 1 and tank 3, such as figure 2 , the stainless steel capillary line 2 is welded and fixed on the cavity inlet 301 on the bottom surface of the storage tank 3 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com