Bainite isothermal heat treatment method for medium carbon silicon manganese chromium nickel series low alloy steel

A medium-carbon silicon-manganese-chromium-nickel system and carbon-silicon-manganese-chromium-nickel system technology, applied in the field of warm heat treatment, can solve problems such as failure to meet the high strength and toughness requirements of key components, unqualified product performance, and hindering the progress of aircraft manufacturing. Excellent stress corrosion resistance, improved comprehensive mechanical properties, and good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The bainite isothermal heat treatment of 40SiMnCrNiMoV series medium carbon silicon manganese chromium nickel series low alloy steel is achieved through the following steps:

[0026] Step 1) Austenitizing the medium-carbon silicon-manganese-chromium-nickel low-alloy steel. Described austenitizing temperature is A of medium carbon silicon manganese chromium nickel series low alloy steel. c3 Above 30℃~50℃, the holding time is 10min~30min, where A c3 is the final temperature when the ferrite is completely transformed into austenite during heating;

[0027] Step 2) performing isothermal quenching at a temperature of 5°C to 60°C above the martensitic transformation starting point Ms of the medium carbon silicon manganese chromium nickel series low alloy steel, and the holding time is 120 to 180 minutes;

[0028] Step 3) Temper the medium carbon silicon-manganese-chromium-nickel-based low-alloy steel treated in step 2) at 10°C to 60°C higher than the austempering temperatur...

Embodiment 2

[0035] The difference between this example and Example 1 is that the holding time in step 2) is 180-240 min. Others are the same as in Example 1.

Embodiment 3

[0037] The bainite isothermal heat treatment method for the carbon-silicon-manganese-chromium-nickel-based low-alloy steel in the 40SiMnCrNiMoV series of the present embodiment is achieved through the following steps: heat the carbon-silicon-manganese-chromium-nickel-based low-alloy steel in the 40SiMnCrNiMoV series at 850° C. to 900° C. After the austenitizing treatment is completed under heat preservation for 15 to 20 minutes, isothermal quenching is performed at a temperature of 250 to 300 degrees, and the temperature is maintained for 120 to 180 minutes, and then tempered at 10 to 60 degrees above the quenching temperature, and the holding time is 30 to 150min.

[0038] The beneficial effects of the heat treatment method for the carbon-silicon-manganese-chromium-nickel low-alloy steel in the 40SiMnCrNiMoV series of the present embodiment are verified through the test in Table 2.

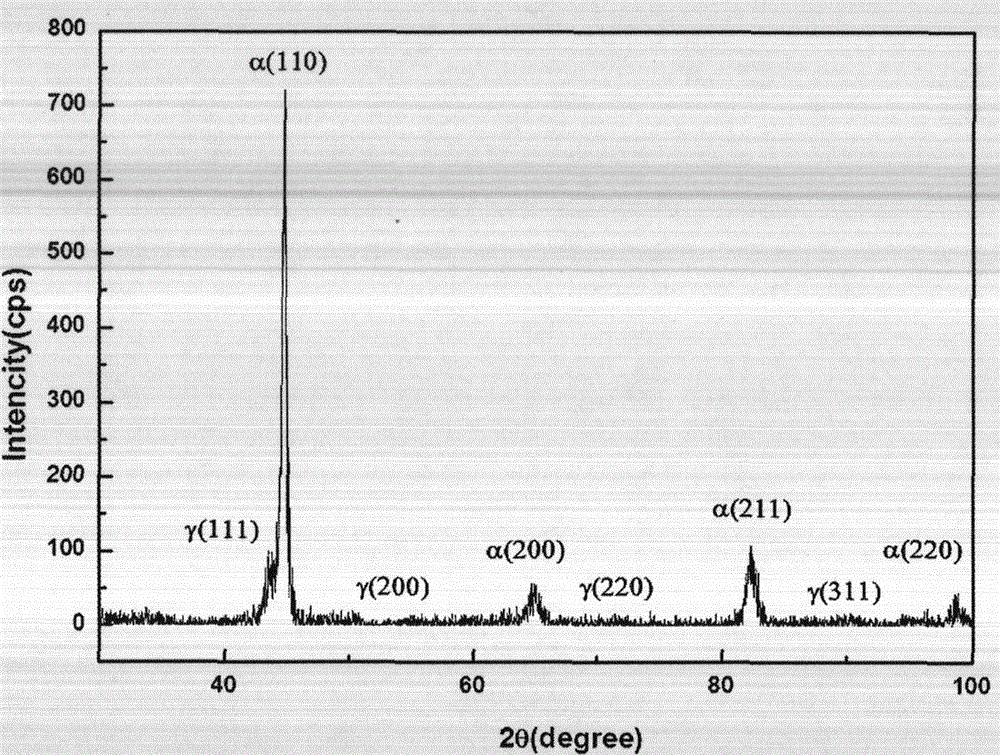

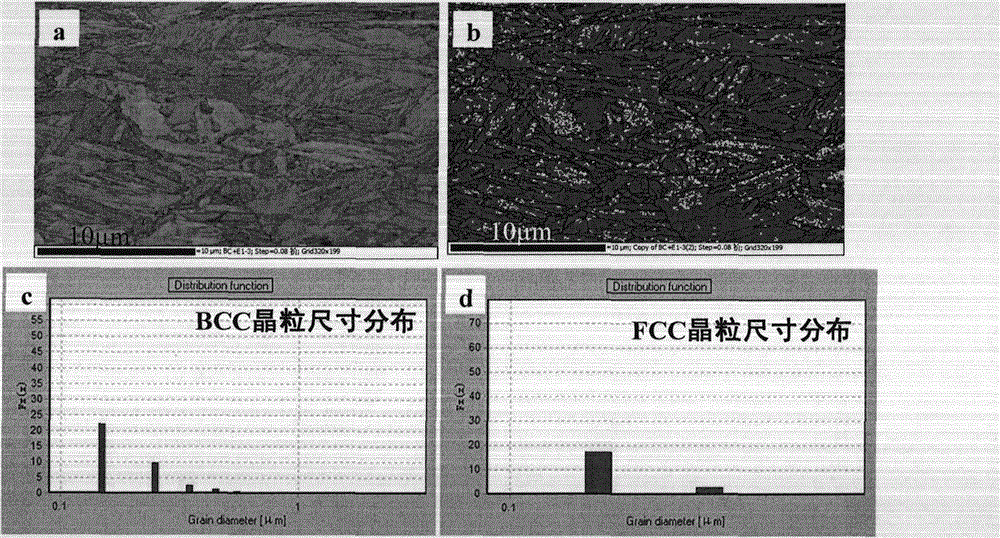

[0039] The metallographic photo of 40SiMnCrNiMoV steel after treatment in test 2 is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com