Soil and structure contact surface testing machine

A contact surface, testing machine technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as uneven friction, reduced data reliability, and distorted test results. Constant area, elimination of strain localization, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

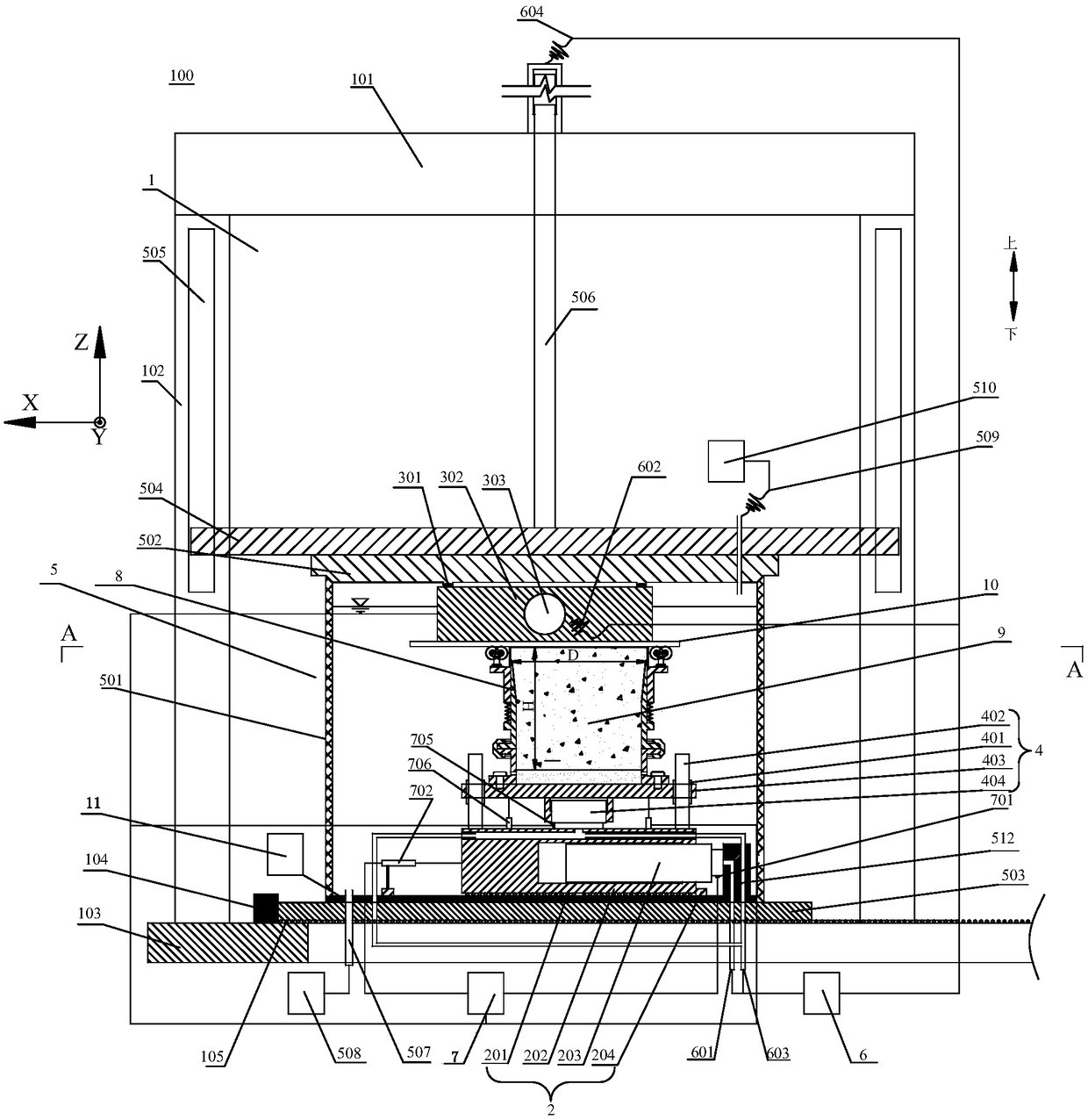

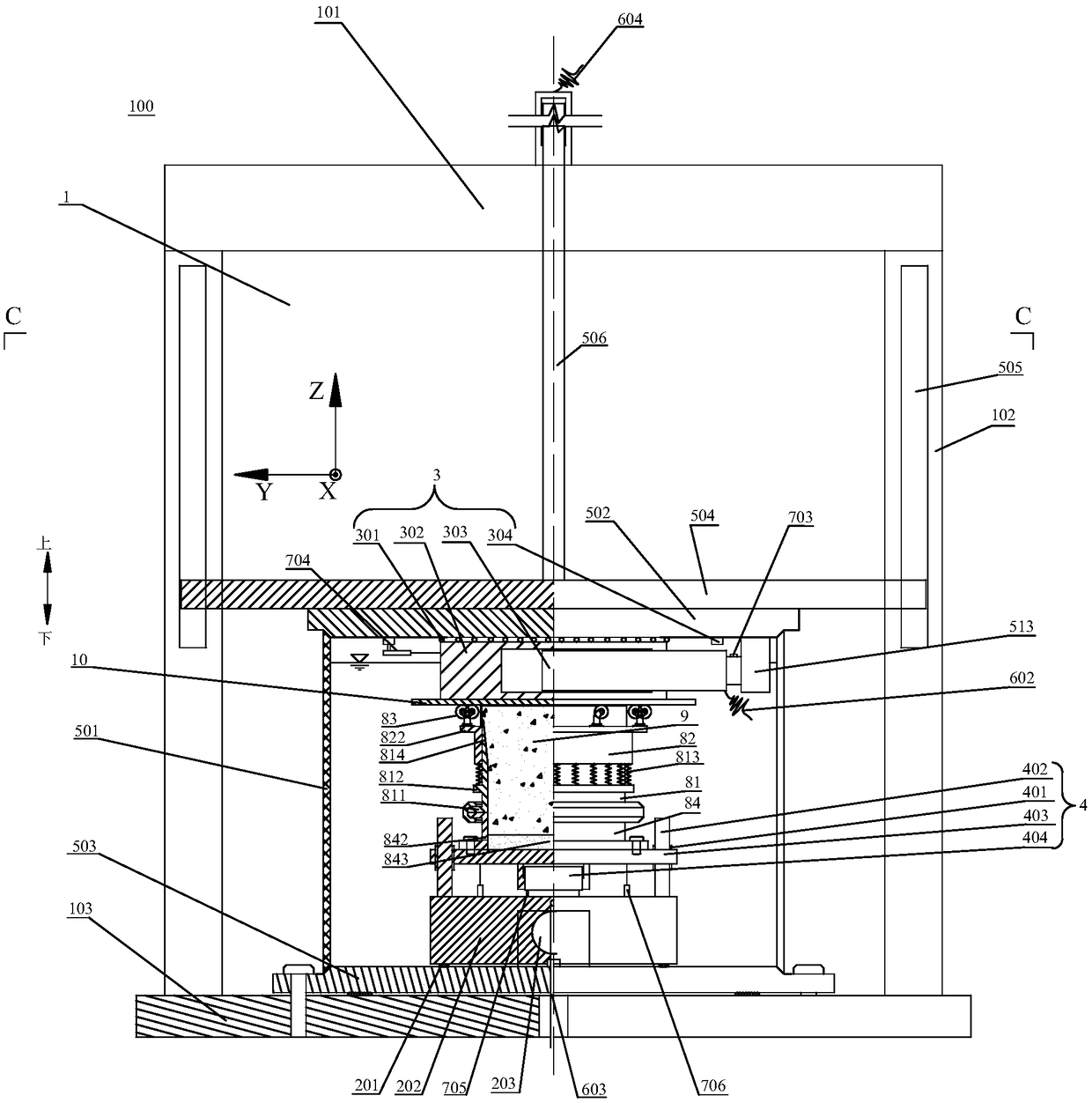

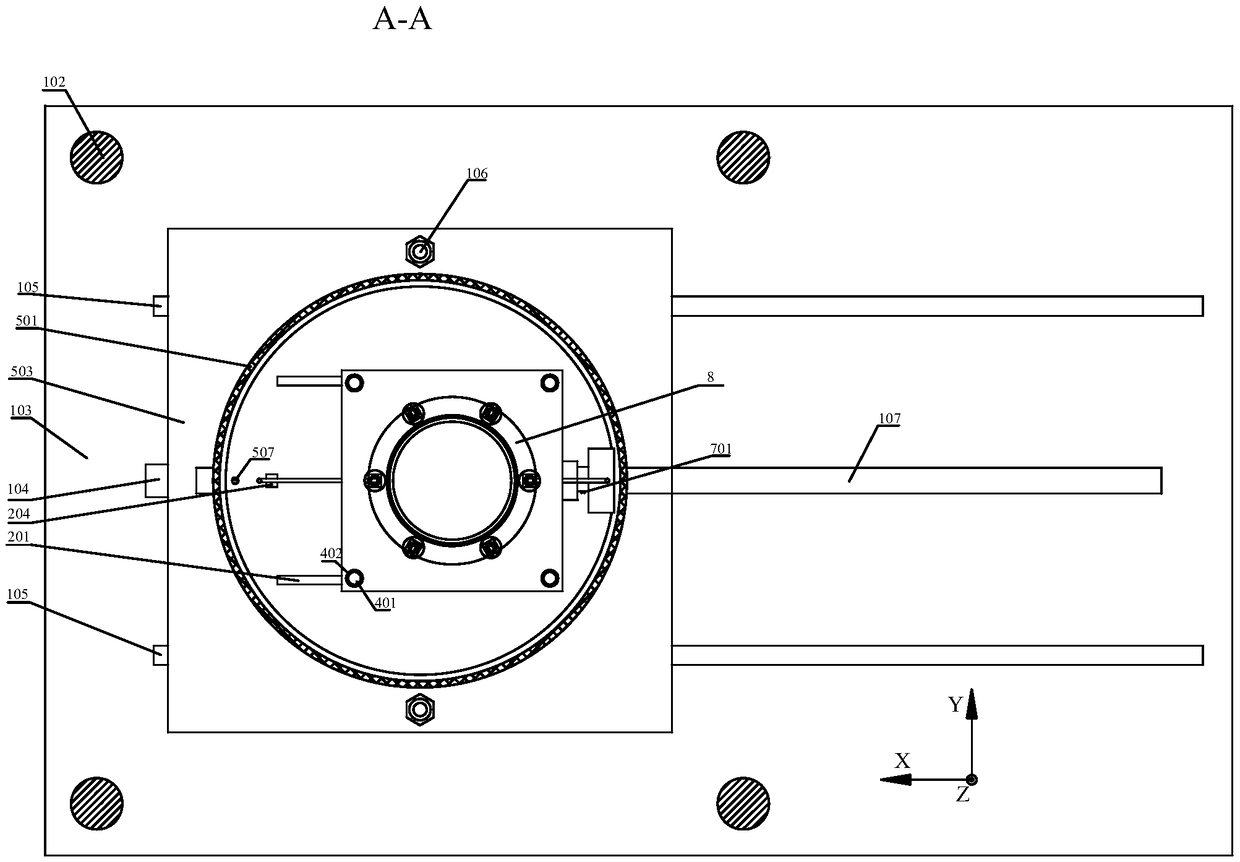

[0074] Combine the following Figure 1-Figure 6 , introduce the content of the testing machine of a specific embodiment of the present invention in detail:

[0075] The structure of the testing machine in this embodiment is shown in the figure. The testing machine includes a main frame 1, an X-direction motion system 2, a Y-direction motion system 3, a Z-direction motion system 4, a confining pressure chamber system 5, and a hydraulic loading and control system. 6 and data acquisition system 7, structural panel 10 temperature control system 11.

[0076] The base 103 and the top board 101 are disposed opposite to each other, and the two ends of the column 102 are respectively connected to the top board 101 and the base 103 .

[0077] The confining pressure chamber system 5 includes a confining pressure chamber 501 , a confining pressure chamber lifting module, a confining pressure chamber bottom plate 503 and a confining pressure control module 510 . The confining pressure ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com