End shaft sealing structure of compressor

A sealing structure and compressor technology, applied in the field of compressors, can solve the problems of inability to completely block water from entering outwards, bearing corrosion and damage, etc., and achieve the effects of good sealing, low friction and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

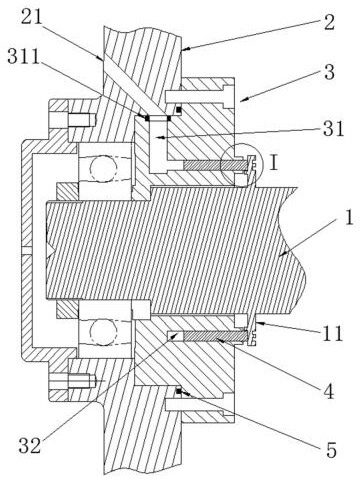

[0020] combine Figure 1-2 As shown, a compressor end shaft sealing structure includes a rotating shaft 1 and an end cover 2, and a bearing is arranged between the two, so that the rotating shaft 1 can rotate. The inner side of the end cover 2 is sealed with a sealing member 3, and a plurality of through holes can be provided on the sealing member 3, and a plurality of threaded holes are arranged on the inner side of the end cover 2, and the two are fixed together by bolts, and the end cover 2 is in the A second sealing ring 5 is provided on the inner side of the threaded hole, so that the two are connected in a sealed manner. The end cover 2 is provided with a first ventilation hole 21 for connecting the compressed gas source, the sealing member 3 is provided with a second ventilation hole 31 which communicates with the first ventilation hole 21, and the sealing member 3 is provided with a second ventilation hole 31 communicating with the first ventilation hole 21. A sliding...

Embodiment 2

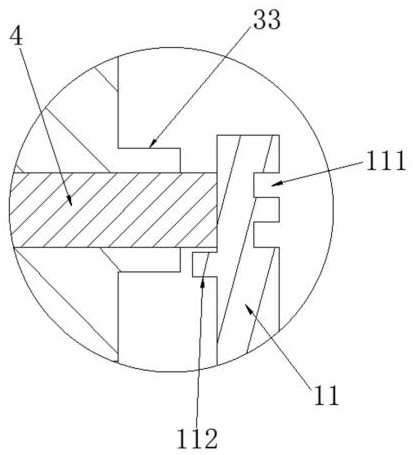

[0026] combine figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the sealing member 3 is provided with a support portion 33 at the outer end of the sliding cavity 32, and the supporting portion 33 is distributed on both sides of the sliding cavity 32. Cylindrical boss. On the one hand, the support part 33 can support the outer end of the cylindrical sealing ring 4 to reduce its deformation under pressure; figure 2 It can be seen that the wall thickness of the support portion 33 is relatively small, which can improve the heat dissipation efficiency when it is in contact with water.

Embodiment 3

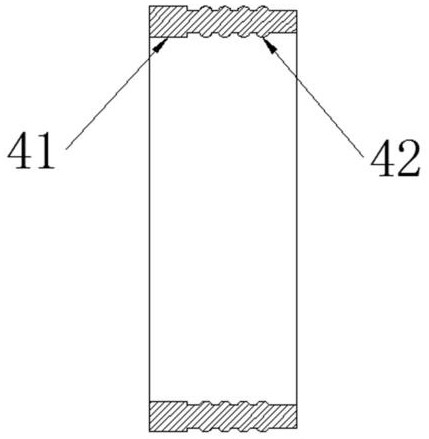

[0028] combine Figure 3-4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the end of the cylindrical sealing ring 4 close to the second ventilation hole 31 is provided with a pushing portion 41, and the inner and outer surfaces of the pushing portion 41 are respectively convex. For the inner and outer surfaces of the cylindrical sealing ring 4 , a plurality of convex rings 42 are also provided on the inner and outer sides of the cylindrical sealing ring 4 . Under this structure, the pushing portion 41 and the convex ring 42 and the two sides of the sliding cavity 32 can form a larger pressure, the deformation is larger, and the sealing effect is better, and the main body of the cylindrical sealing ring 4 may not be in contact with the sliding cavity 32. Pressure or a certain gap is formed on both sides of the seal, so that the contact area between the two is smaller and the frictional force is smaller, so that the cylindrical sealing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com