Fixed die table for PC prefabricated parts and production line of PC prefabricated parts

A technology of prefabricated components and fixed molds, applied in manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of difficult horizontal hoisting of wall panels, difficult maintenance of fixed mold tables, manual vibration, etc., to achieve structural Simple and reliable, effective use of space, and the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be construed as a limitation on the technical solution.

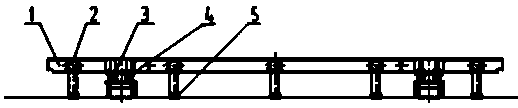

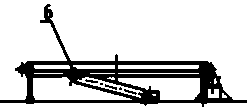

[0016] like figure 1 , figure 2 As shown, the fixed formwork platform includes a platen 1, the bottom surface of the platen 1 is connected with the shock absorbing spring 5 installed on the ground through the support seat, several vibrators 2 are installed on the table top of the platen 1, and the hydraulic ejector machine 6 is installed On the ground below the platen 1 , the ejector rod of the hydraulic ejector 6 is hinged to the rotating support seat 3 on the bottom surface of the platen 1 through the pin shaft 4 , and the hydraulic ejector 6 realizes the overturning operation of the platen 1 .

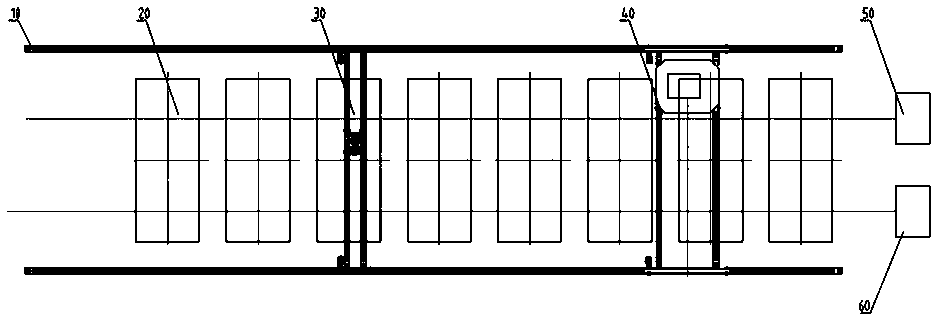

[0017] like image 3 , Figure 4 As shown, a plurality of fixed mold tables are arranged and combined to form a mold table row 20, and above the mold table row 20, a distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com