Patents

Literature

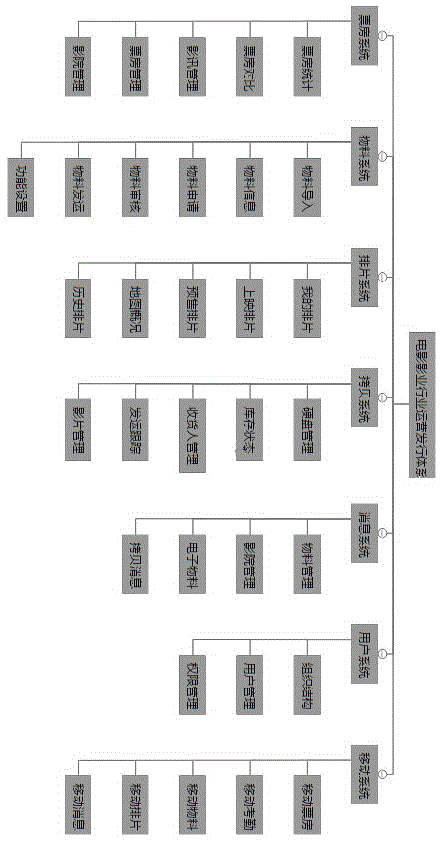

57results about How to "Flexible ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic high molecular composite flocculant and preparation method thereof

ActiveCN101973688ALow costSufficient sourceSludge treatment by de-watering/drying/thickeningChlorideSuspended matter

The invention discloses an organic high molecular composite flocculant which is mainly used for municipally or industrially dewatering sludge and a preparation method thereof, which solve the problems of complex treatment process, agent waste, secondary pollution and the like existing in the prior art. The flocculant comprises polyacrylamide, polydimethyldiallylammonium chloride and modified starch serving as raw materials and the dry weight ratio of polyacrylamide to polydimethyldiallylammonium chloride to modified starch is 4-9:0.5-5:0.5-5, wherein tap water or de-ionized water is used as a dispersing agent; and the liquid organic high molecular composite flocculant, of which the molecular weight is 4,000,000 to 12,000,000, the ionization degree is 40 to 80 percent and the effective content of the raw material is 1 to 5 percent based on dry weight, is prepared by dispersing the materials in a reactor at the temperature of between 10 and 50 DEG C with stirring and compounding for 0.5 to 3 hours. The flocculant has the advantages of sufficient raw material sources, low cost, simple process flow, stable performance and high suspension separation speed, is reasonably prepared and quickly dissolved and is safe to operate, and convenient to use, saves the amount, obviously improves the dehydration efficiency, expands the application range, prevents fluctuation of treatment effect and reduces secondary pollution.

Owner:国能辽宁环保产业集团有限公司材料分公司

Method for producing organic and inorganic compound fertilizer by utilizing duck dropping source

InactiveCN101628841AEnsure a virtuous circleShorten the fermentation cycleMagnesium fertilisersAlkali orthophosphate fertiliserInorganic compoundOxygen

The invention discloses a method for producing an organic and inorganic compound fertilizer by utilizing a duck dropping source, which comprises the following steps: regulating C / N ratio and water content of organic wastes; adding a CM fermenting agent to the organic wastes; carrying out aerobic fermentation and secondary fermentation on the organic wastes and then pulverizing the organic wastes; adding large and intermediate trace element chemical fertilizers and a fertilizer regulator or a plant growth regulator to the pulverized organic wastes; and granulating to prepare a commercial organic fertilizer. The invention has simple method, can process the duck dropping source at a time and has flexible nutrient proportioning and strong adaptability of the produced organic fertilizer and obvious fertilizer yield increasing effect.

Owner:JIANGSU YIHAI FERTILIZER

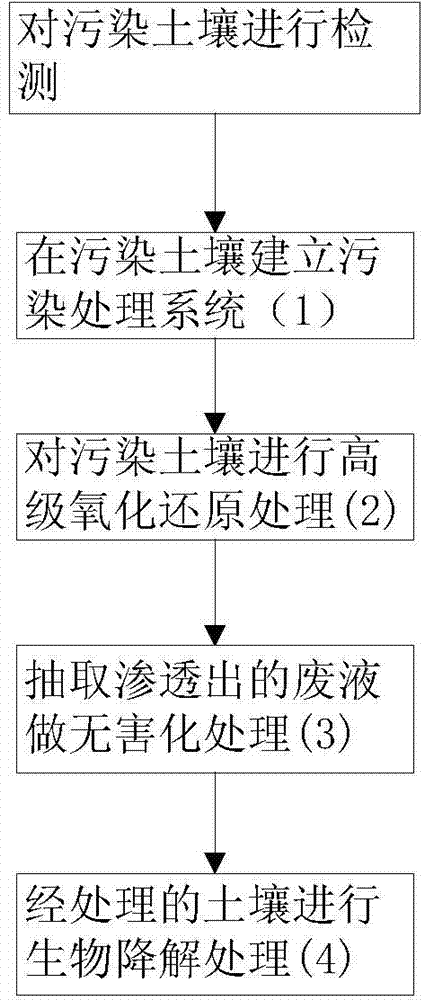

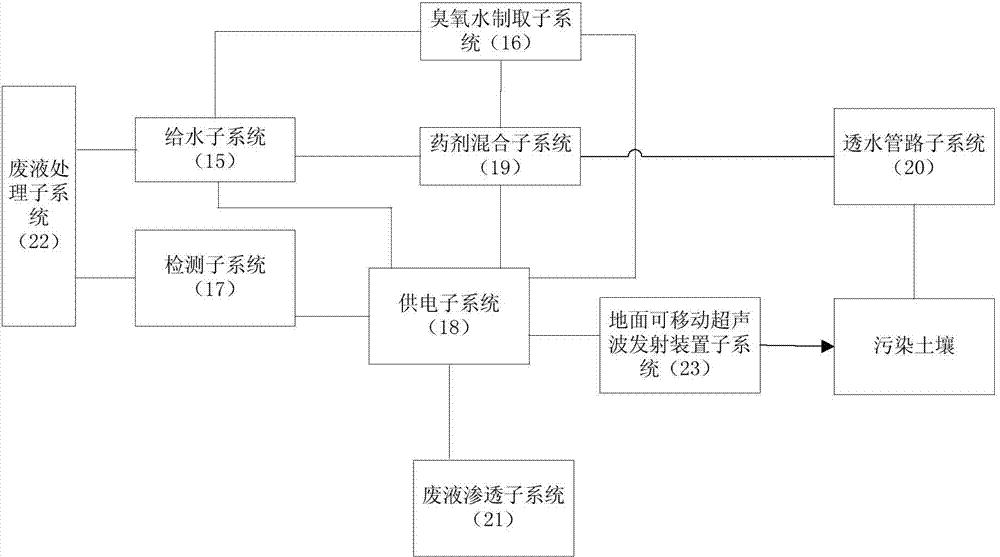

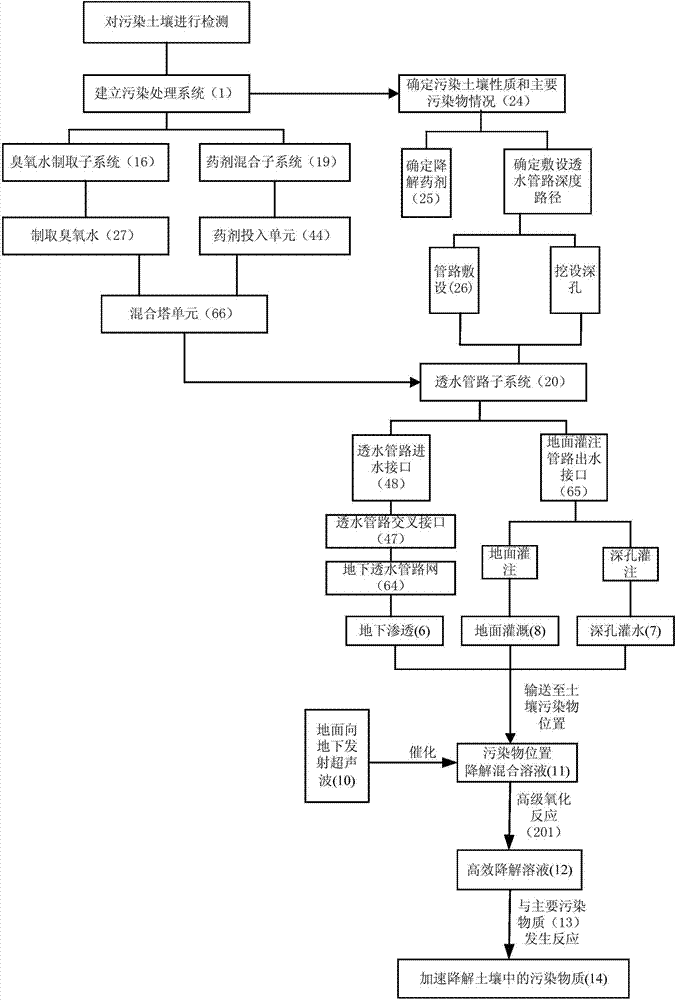

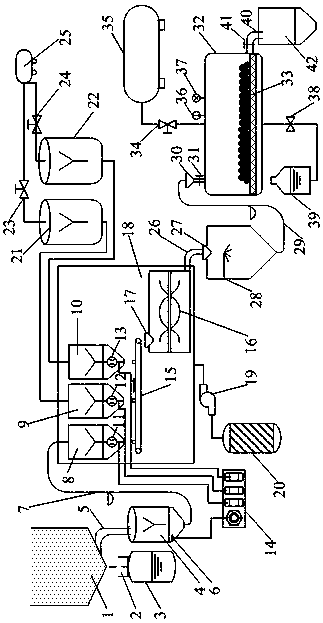

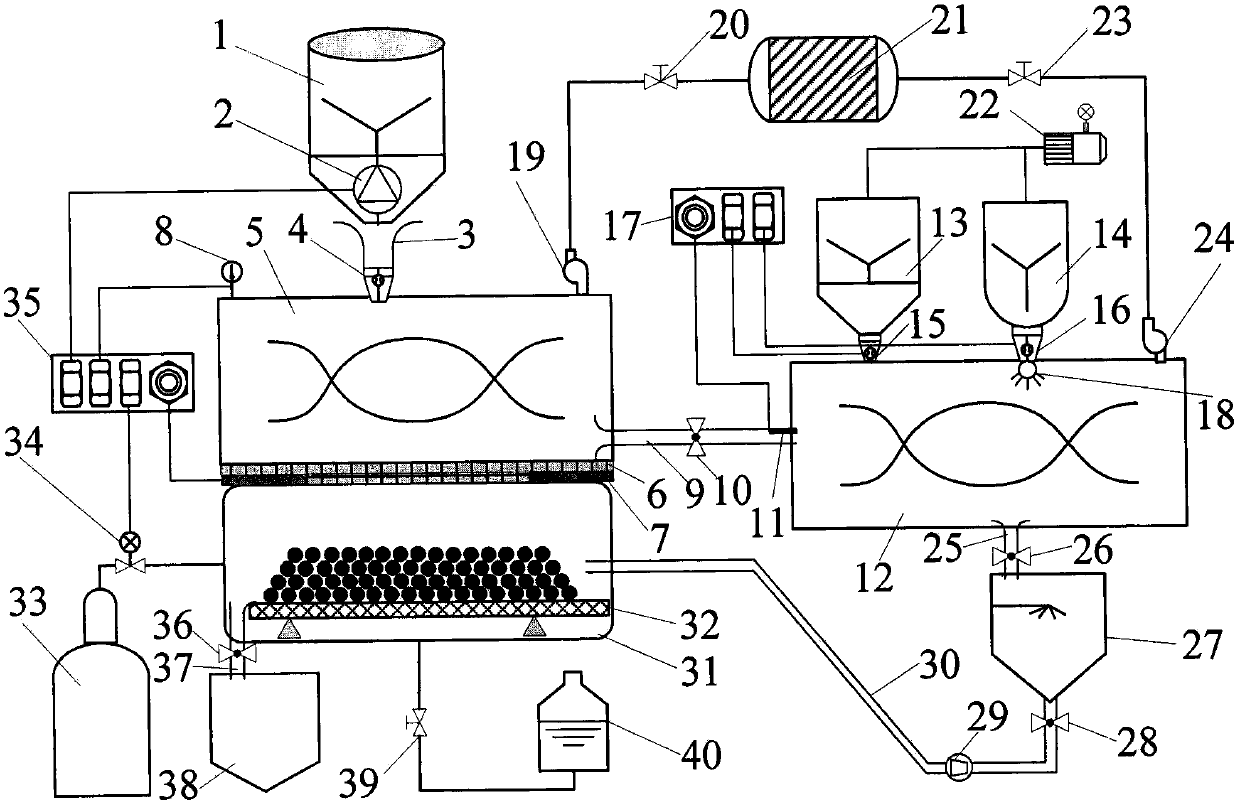

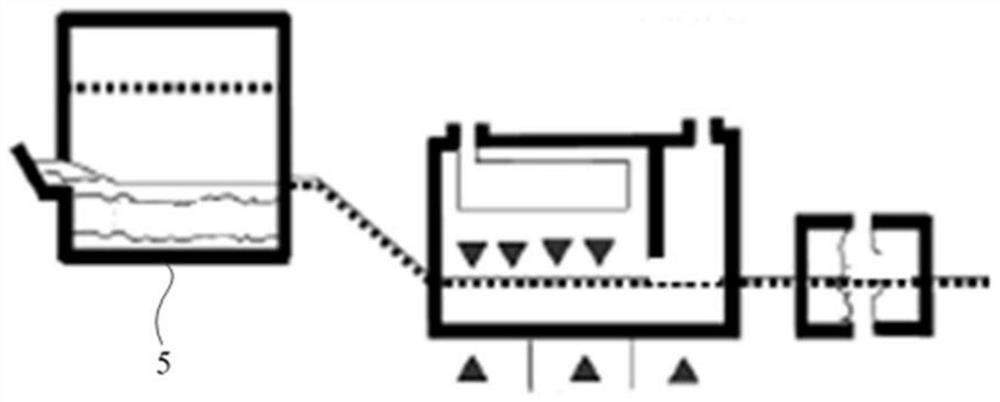

Advanced redox in-situ treatment system and method for restoring polluted soil

ActiveCN103920703AEfficient degradationPromote decompositionContaminated soil reclamationLiquid wasteTreatment system

The invention discloses an advanced redox innocent treatment system and method for waste pollutants, belonging to the technical fields of pollution treatment and restoration and environmental protection. The innocent treatment system comprises a waste degradation subsystem, a waste liquid treatment subsystem, an ozone water preparation subsystem, a degradation reagent addition subsystem, a detection control subsystem and a water level control subsystem. The method comprises the following steps: determining the type of waste pollutant, selecting the degradation reagent, pouring the waste pollutant into a treating pond, carrying out advanced redox treatment on the waste pollutant, carrying out innocent treatment on the treated waste liquid, reutilizing, and carrying out biodegradation treatment on the treated soil. The system and method have the advantages of obviously higher degradation efficiency and short time consumption, can treat organic pollutants within 2-3 days, can treat heavy metal pollutants within 3-5 days, greatly shorten the pollutant treatment time, and lower the cost by more than 70%.

Owner:QINGDAO ODO ENVIRONMENTAL TECH CO LTD

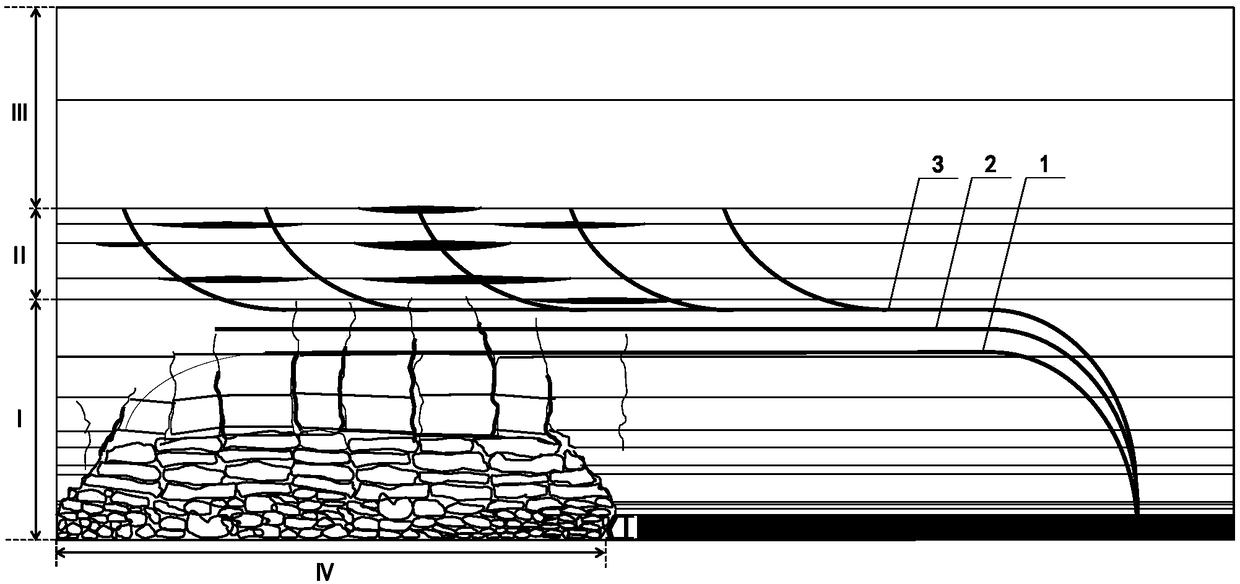

Coal mine working face top plate high position directional drill hole group pressure relief gas extraction method

ActiveCN108506037AImprove drilling utilizationAvoid high extraction tunnelingDirectional drillingGas removalHigh concentrationDesorption

The invention discloses a coal mine working face top plate high position directional drill hole group pressure relief gas extraction method. According to the principle, the coal mine working face topplate high position directional drill hole group pressure relief gas extraction method comprises the steps that before a working face is stoped, by constructing a high position directional drill holegroup along the working surface in an air return way of the working surface, main hole sections of high position directional drill holes are extended in an O-shaped circle fissure zone of a goaf formed after the working face is stoped, and lower position drill holes are appropriately lowered at the position of open-off cut close to the working face, crossing branch holes facing upward are constructed in upper position drill holes, after the working face is mined by adopting the combining extraction of all drill holes, gas guiding of the fissure zone is carried out, and pressure relief and desorption of gas in the fissure zone are carried out. The coal mine working face top plate high position directional drill hole group pressure relief gas extraction method can play a dual role of reducing the gas concentration in the corners of the working surface and in the return current and extracting high-concentration gas in the pressure relief and desorption zone of the goaf, gas control of theworking face is achieved, and the recycling of gas resources is realized.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

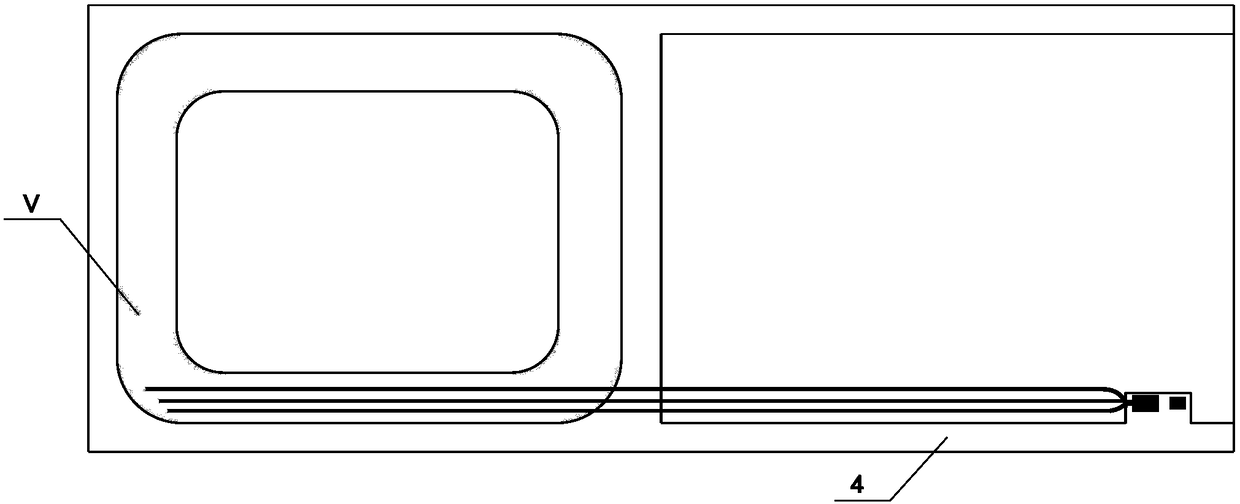

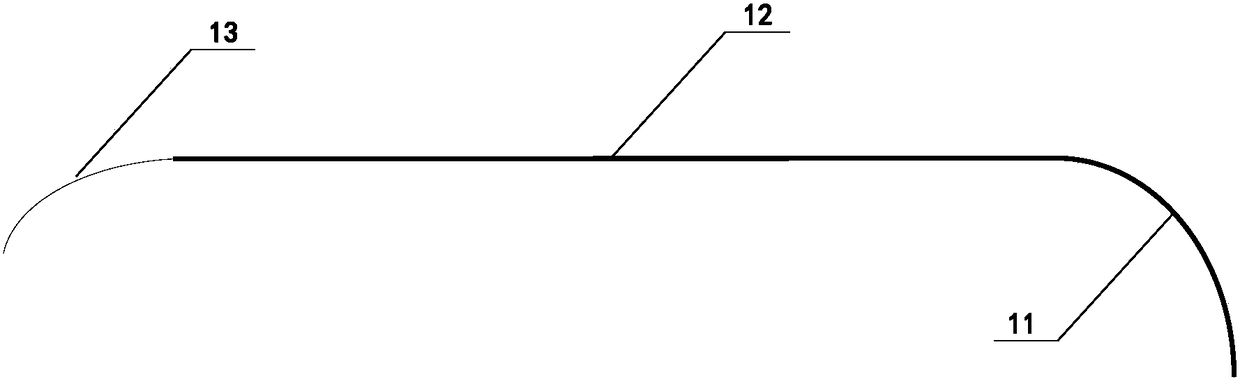

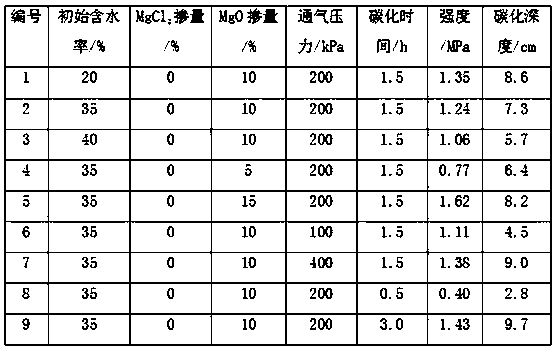

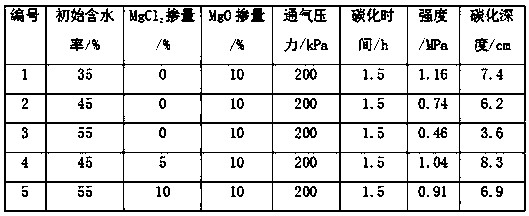

Method for silt soil with ectopic activated magnesium oxide carbonization and solidification

ActiveCN108086297AAdjust dosage in real timeFlexible ratioSludge treatment by de-watering/drying/thickeningSoil preservationSoil propertiesPrill

The invention discloses a method for silt soil with ectopic activated magnesium oxide carbonization and solidification, and belongs to the field of hydraulic and civil engineering. The method includesthe steps of a sludge pretreatment, a uniform mixing of a curing agent, a silt granulation, a carbon dioxide carbonization, a waste gas / waste liquid collection, and a resource utilization. The supplyof the curing agent is regulated by actual measure a water content rate, and a diameter of a grain and a carbon dioxide pressure are regulated according to a soil property, so that a full mixing of the silt and the curing agent and the rapid carbonization of magnesium oxide solidified the sludge grains are realized. Dust and carbon dioxide are absorbed during the operation process to avoid secondary pollution. The method is safe, simple, low in carbon, environmental, and high in continuous operation rate, and the problem of sludge treatment and engineering application is solved. The silt carbonized grains have the advantages of low moisture content, high hardness, high shear strength, large friction coefficient and the like. The silt carbonized grains can be used as a filler such as a roadbed, an airport runway and an engineering backfill, and the reclamation of the slit / sludge and the carbon dioxide is realized. The method for the silt soil with the ectopic activated magnesium oxidecarbonization and solidification has great significance of the engineering construction.

Owner:SOUTHEAST UNIV

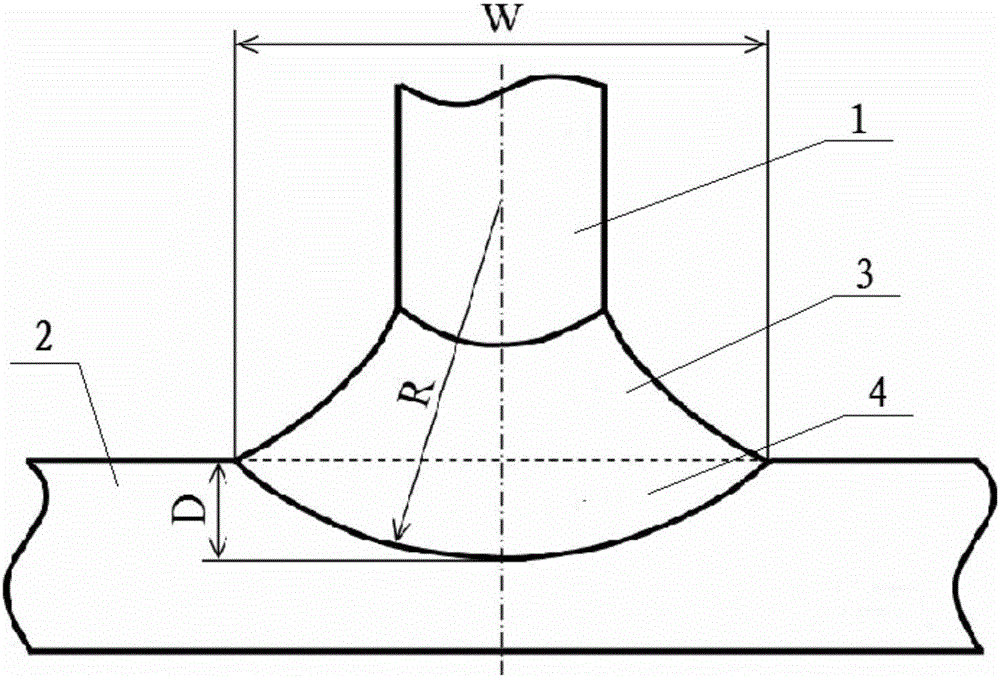

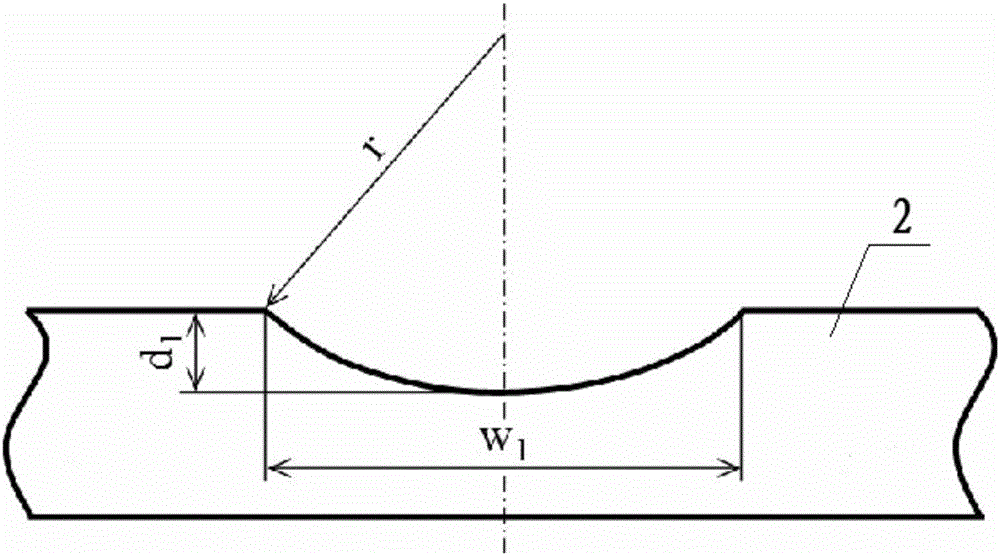

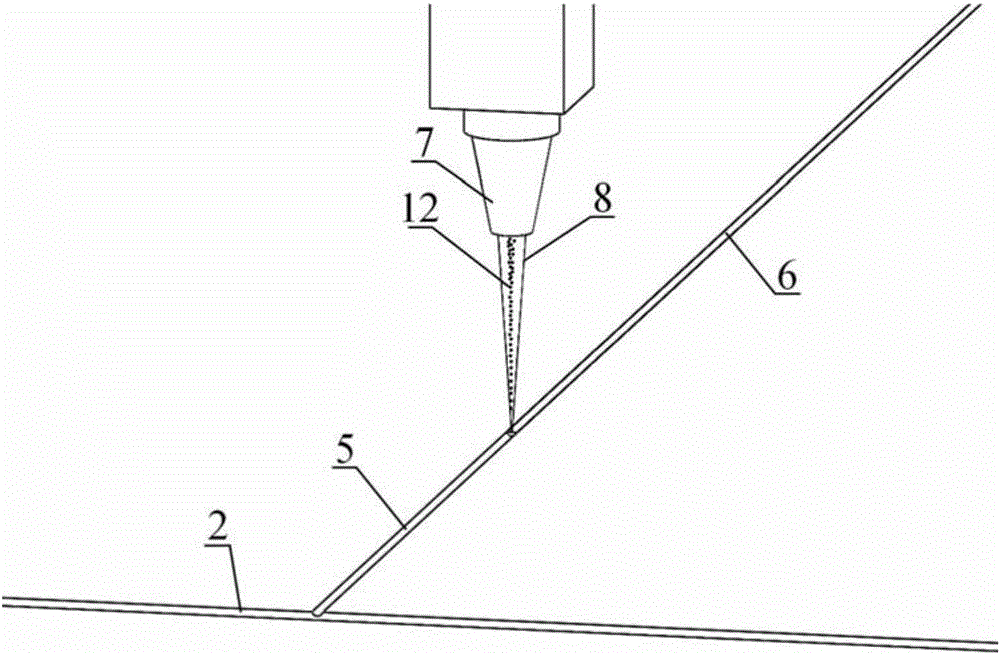

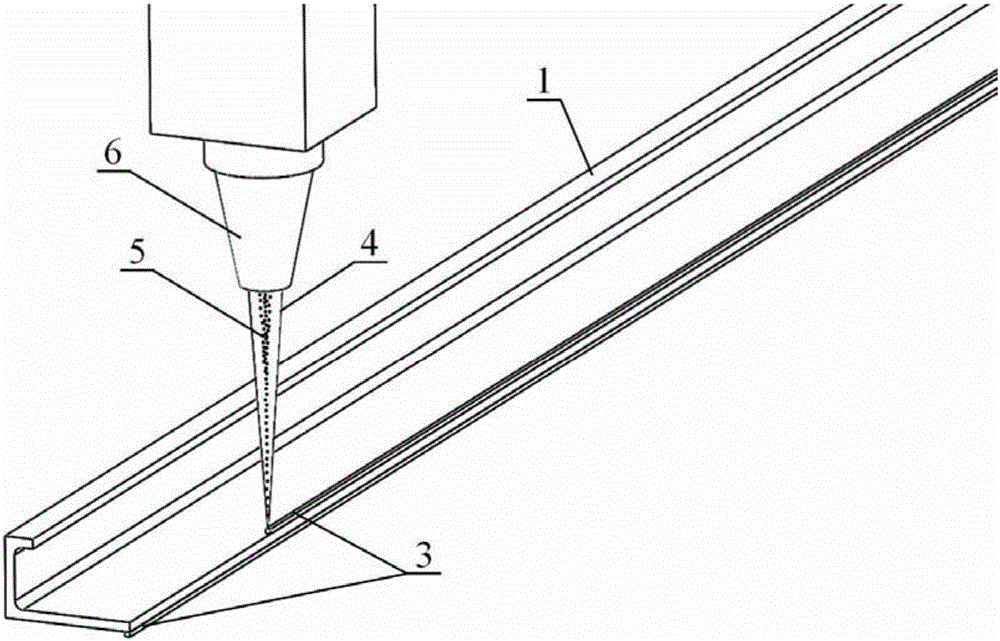

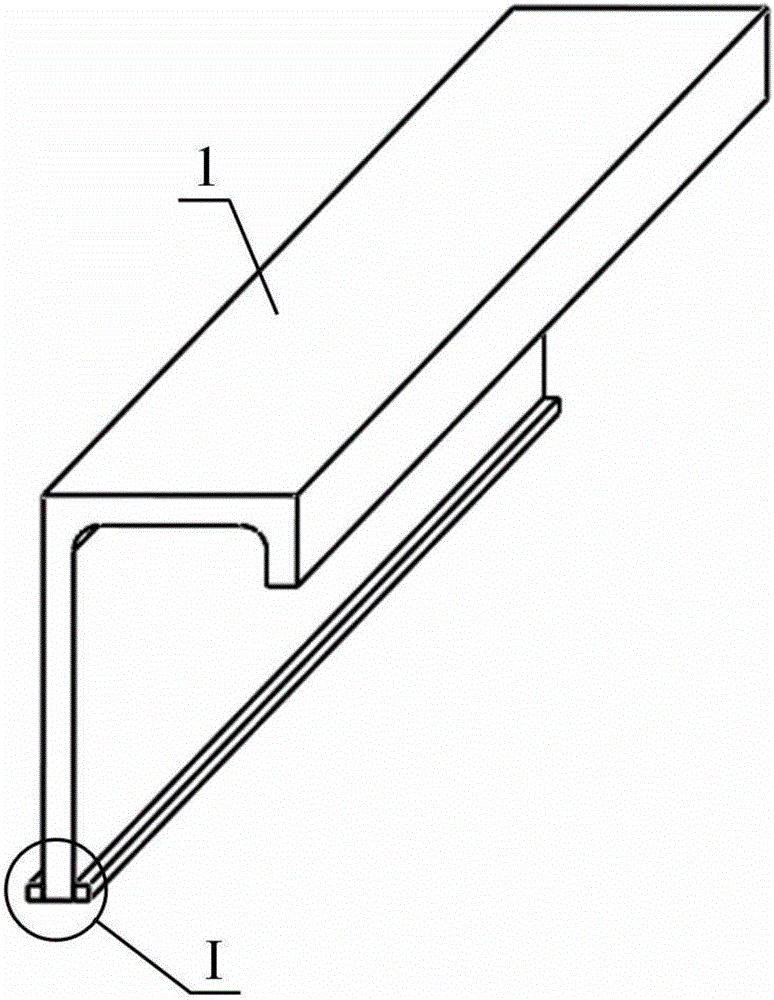

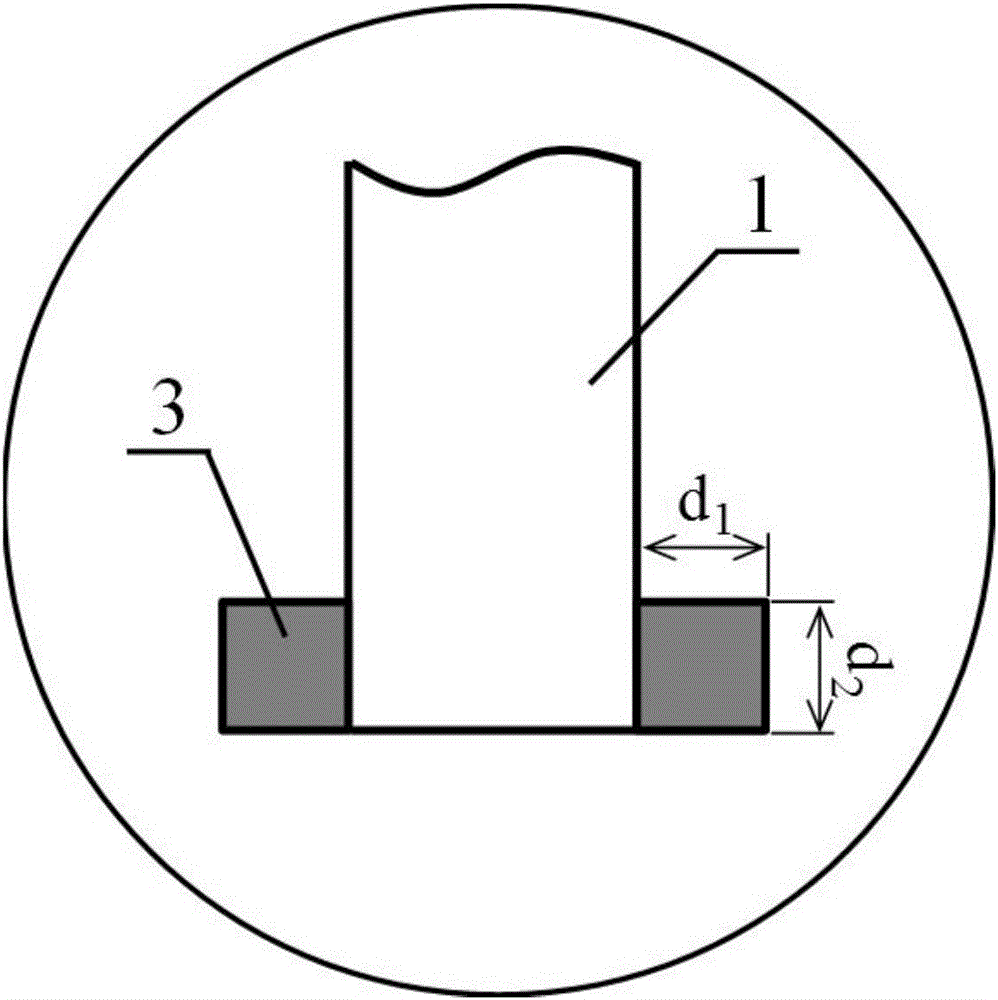

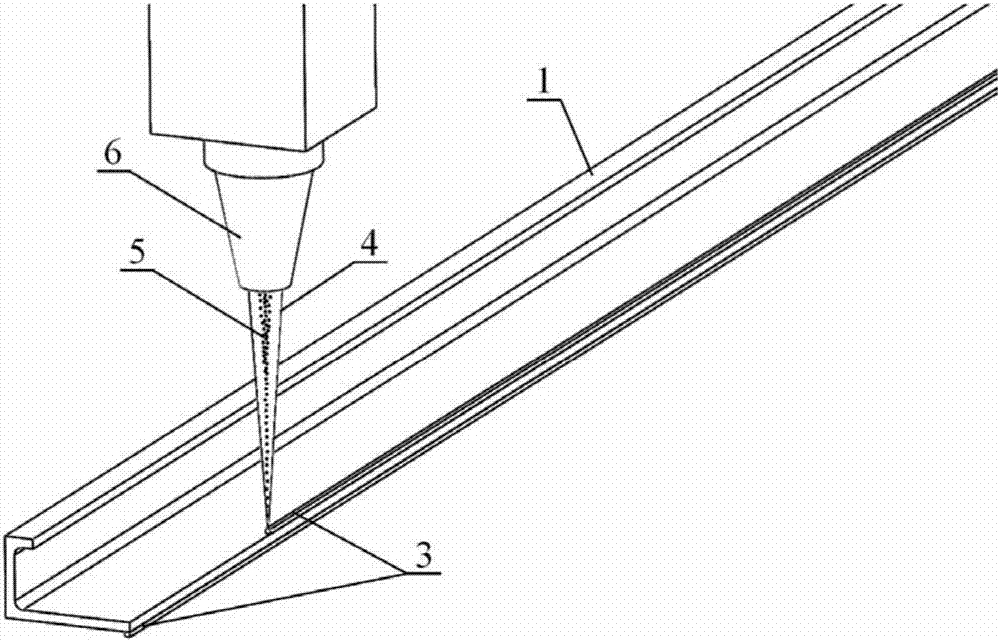

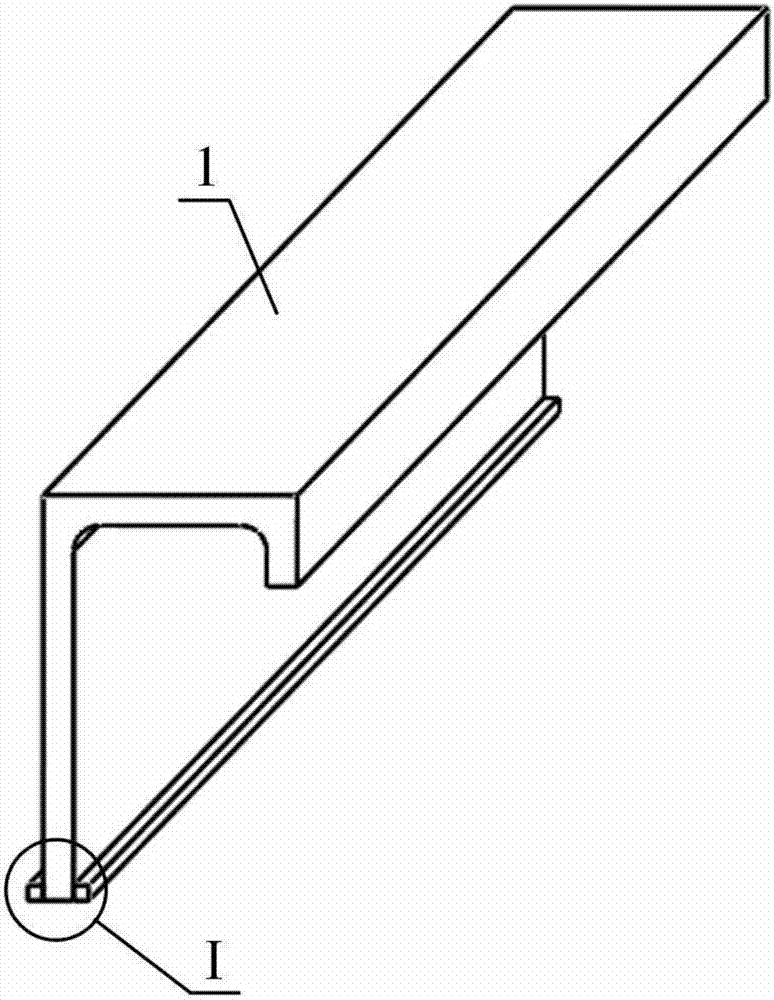

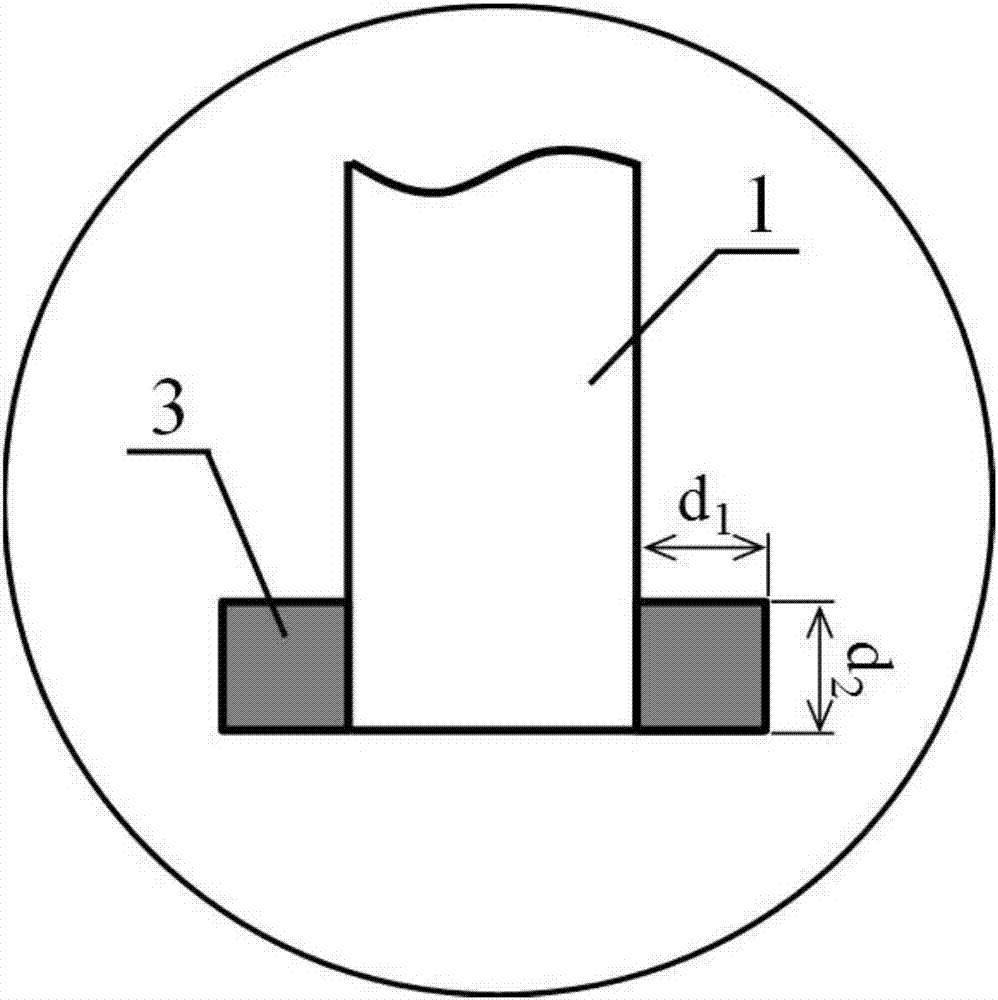

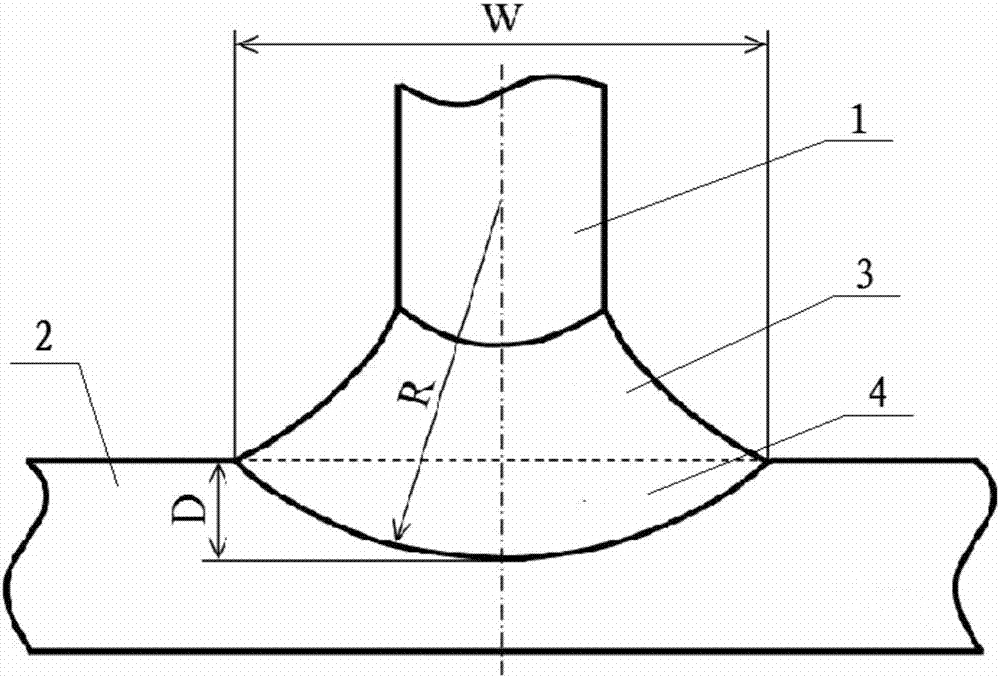

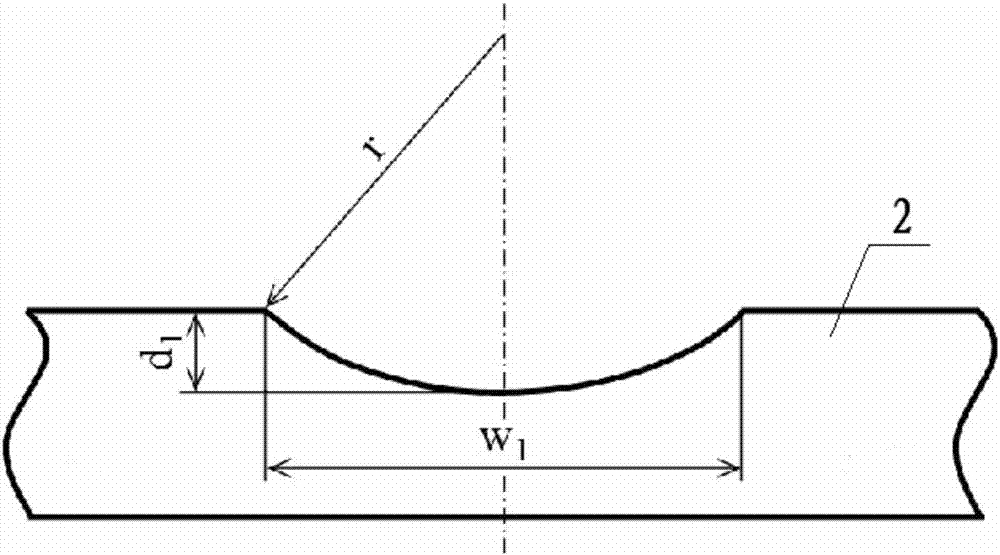

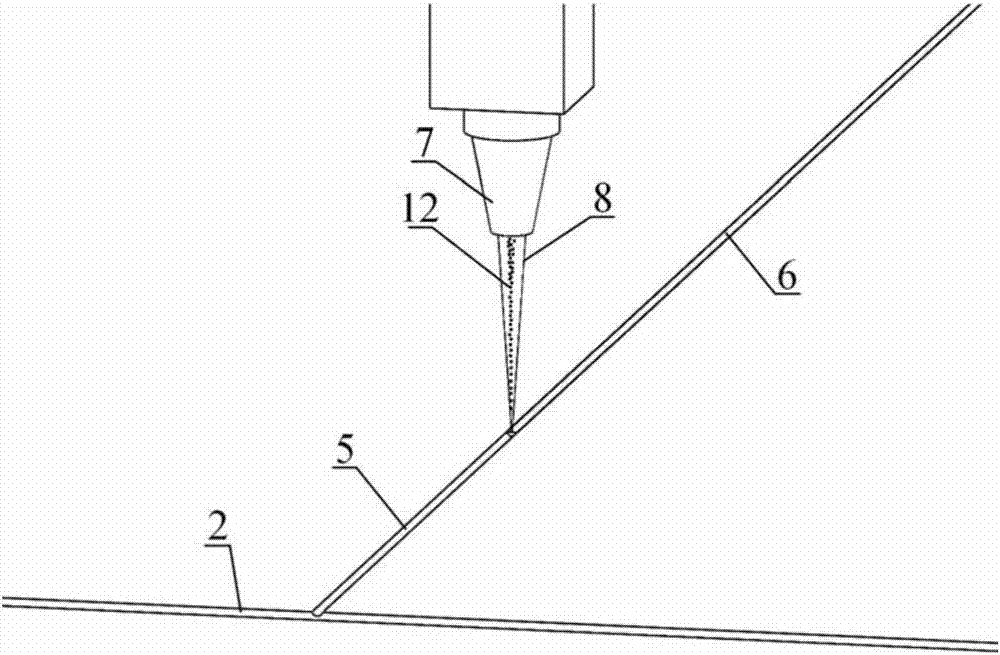

Double-side laser welding method for powder metallurgy control

ActiveCN105728944AImprove mechanical propertiesEvenly regulatedVehicle componentsMetal working apparatusAlloyLaser beams

The invention discloses a double-side laser welding method for powder metallurgy control, relates to a double-laser beam welding method, and solves the problem that welding wire elements cannot perform full alloy control for a welding line structure in the double-side laser welding process of a T-shaped structure. The method comprises the following steps: (1) a groove is mechanically milled in the center of a position to be welded on the upper surface of a cover in the welding direction; and the cover is chemically cleaned to remove an oxide film and machining stains; (2) alloy powder is prefilled in the groove to form a deposition layer; a laser cladding head is vertically placed rightly above the groove; the laser powder feeding material adding is performed on the surface of the groove to obtain the deposition layer by using a mode of coaxial feeding of laser beams and the alloy powder; and a deposition material higher than the surface of the cover is grinded off by using a grinding machine, so that a deposition surface is coplanar with the surface of the cover; and (3) the double-laser wire filling welding is performed for a long purlin and the cover to obtain symmetric welding lines on two sides. The method is used for double-laser beam welding of the T-shaped structure.

Owner:HARBIN INST OF TECH

3D additive-manufacturing bilateral laser welding method for T-shaped structure

ActiveCN105710536AImprove mechanical propertiesEvenly regulatedLaser beam welding apparatusMelting tankAlloy

Owner:HARBIN INST OF TECH

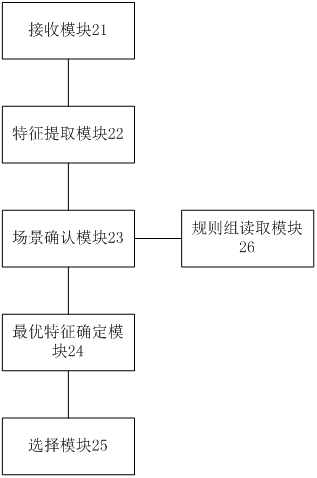

Real-time business risk control system and method based on rule engine

ActiveCN112463840ARealize risk control hit decisionFlexible ratioDatabase management systemsResourcesRisk ControlFeature extraction

The invention provides a real-time business risk control system and method based on a rule engine, which are applied to at least one risk control scene, and the system comprises a configuration layerwhich is used for setting a strategy rule table for each risk control scene, and the strategy rule table comprises at least one strategy rule group; the rule engine is used for carrying out feature extraction on the accessed risk control basic data to obtain extracted features, determining a risk control scene according to the extracted features, and determining feature conditions in a strategy rule group conforming to the extracted features in a strategy rule table corresponding to the risk control scene, and also used for determining an optimal gradient according to a preset strategy combination mode and the feature attributes corresponding to all the feature conditions meeting the extracted features; the system also comprises an action engine which executes an execution action corresponding to the optimal gradient. The invention has the advantages that risk control hit decisions are made for multiple risk control scenes, and multi-strategy, multi-action and multi-gradient optimal gradients under a single risk control scene are effectively selected.

Owner:TIANGU INFORMATION SCI TECH HANGZHOU

Operation and publication system for film trade

InactiveCN104573930APromote healthy developmentFully effective automated controlResourcesCommerceData operationsEngineering

The invention discloses an operation and publication system for a film trade. The operation and publication system is characterized by comprising a box office system for collecting box office data and providing data operation, a unitized material system provided for issuing personnel of the film trade for on-line material declaration, examination and approval and dispatch, a film scheduling system provided for the personnel of the film trade for scheduling film schedules and analyzing data, a copying system provided for the personnel of the film trade to copy a hard disk of a film data encrypting document and dispatch and manage the film data encrypting document, an information system for the personnel of the film trade to update data in a real-time manner and push information, a mobile system provided for the personnel of the film trade to examine the information in real time and dispose affairs, and a subscriber system for the personnel of the film trade for organization structure, personnel function and competence distribution.

Owner:北京光线影业有限公司

Electrolytic polishing solution for aluminum or aluminum alloy and electrolytic polishing method

An electrolytic polishing solution for aluminum or aluminum alloy and an electrolytic polishing method. The electrolytic polishing solution comprises 18%-48% of H2SO4, 20%-43% of H3PO4, 5%-20% of PEG, 6%-18% of C4O6H4KNa and the balance of water. The electrolytic polishing solution provided by the invention contains no nitric acid or chromic acid, and is favorable for environmental protection. The polishing solution has obvious advantages in quality and price compared with other polishing solutions. Due to flexible ratio, the polishing solution has good industrial operability. The electrolytic polishing solution is especially suitable for electrochemical polishing on hard aluminum alloy workpiece requiring high surface quality, and endows full gloss (high brightness of the polished workpiece) on the surface of aluminum or alloy thereof, while smoothening the surface at the same time. Besides, the electrolytic polishing solution has certain leveling effect on the workpieces without mechanical polishing.

Owner:CHONGQING UNIV

Method for manufacturing fertilizer by utilizing organic waster materials from cattle farm

InactiveCN1275912CEnsure a virtuous circleShorten the fermentation cycleBio-organic fraction processingClimate change adaptationVegetationOrganic fertilizer

The invention discloses a fertilizer-generating method using organic waste of cattle farm, which comprises the following steps: adjusting ratio of C / N and moisture; adding aerobic fermenting organism preparation; treating the mixture with aerobic fermentation, second fermentation and disintegration; adding macro-element fertilizer or micro-element chemical fertilizer and modifier of fertilizer or vegetation; granulating and getting organic fertilizer or organic-inorganic compound fertilizer. The invention has property of convenient method, can treat organic waste in cattle farm one time; and products fertilizer with flexible nutrient ratio, high adaptability and significant production-increase effect.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

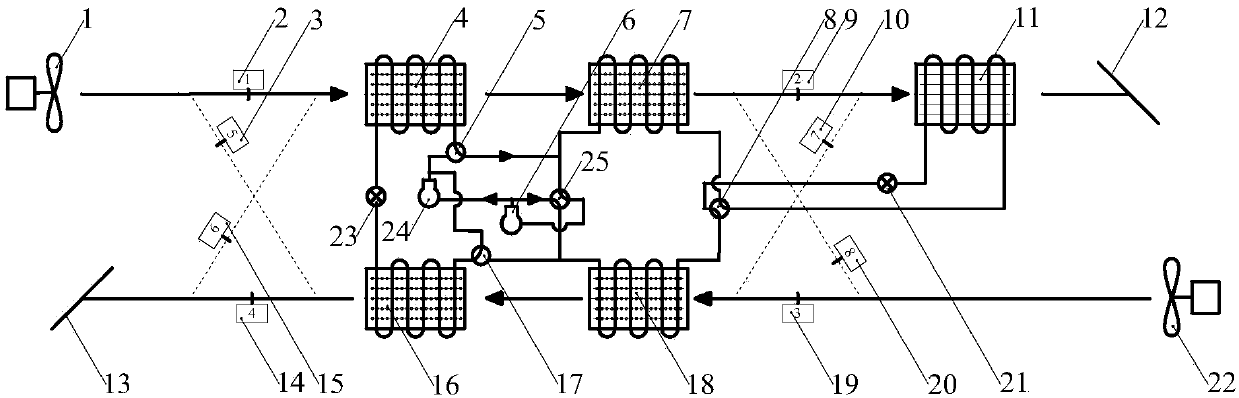

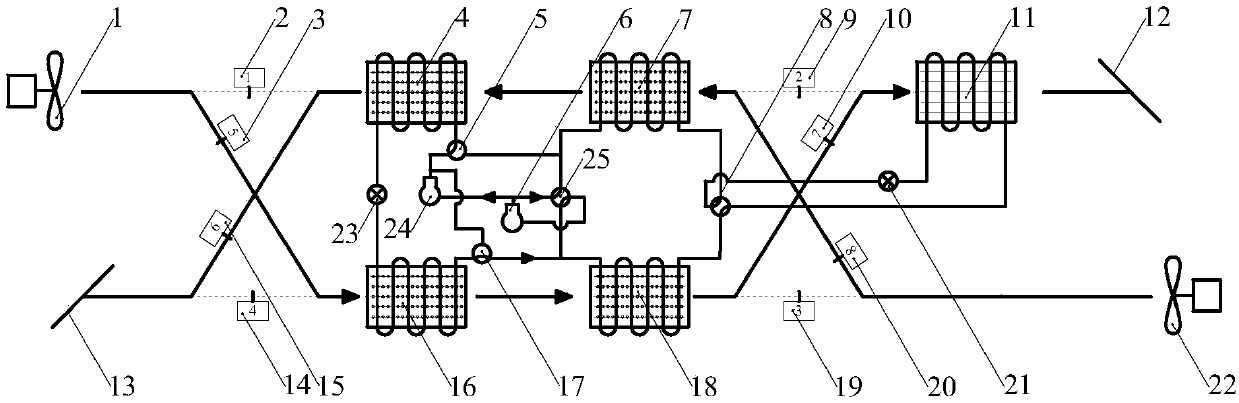

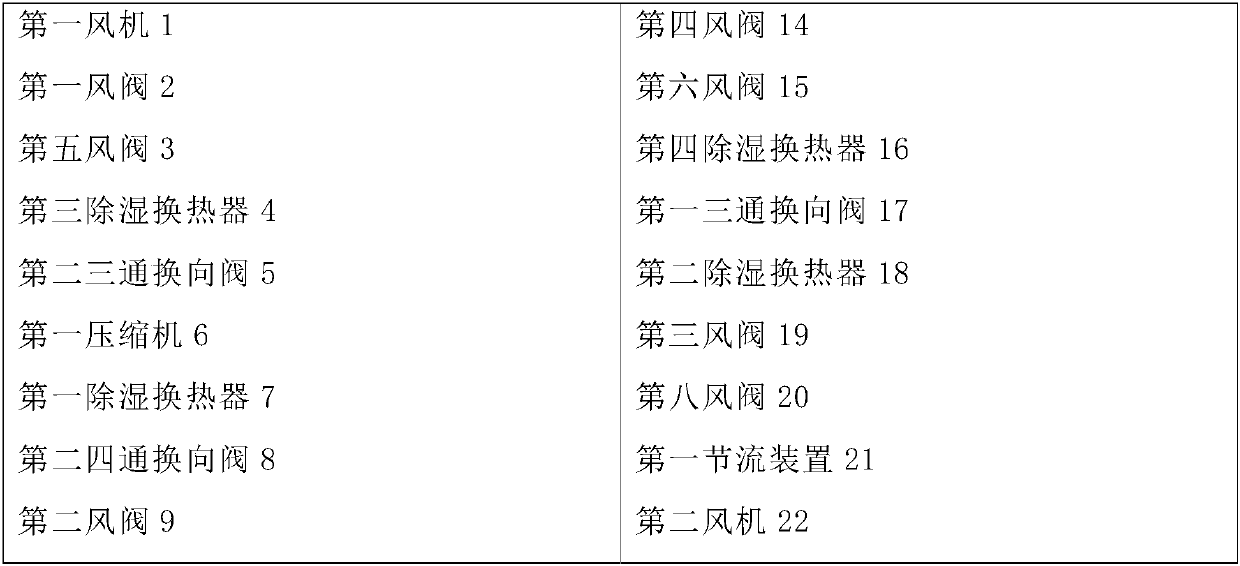

Half-decoupling type graded dehumidifying and cooling dehumidifying heat pump system and method

ActiveCN107726480AAvoid condensationExtend switching timeSubcoolersSpace heating and ventilation detailsDesiccantEvaporation

The invention provides a half-decoupling type graded dehumidifying and cooling dehumidifying heat pump system comprising a refrigerant system and an air system. The refrigerant system comprises two compressors and four dehumidification heat exchangers, two four-way reversing valves, an evaporator, two throttling devices and two three-way reversing valves. The air system comprises two draught fans,eight air valves and two air openings. According to the half-decoupling type graded dehumidifying and cooling dehumidifying heat pump system, the dehumidification heat exchangers at different operation pressures are connected in parallel, the evaporation side at the low pressure grade is connected with a dehumidification evaporator and the evaporator in series. A high-pressure dehumidification evaporator adopts a drying agent with a uniform adsorption speed to achieve heat and humidity load pretreatment, condensation of the high-pressure dehumidification evaporator is prevented through a highevaporator temperature, and meanwhile the dew point of air entering the low-pressure dehumidification evaporator is lowered; the low-pressure dehumidification evaporator adopts a drying agent with high adsorption capacity to achieve heat and humidity load efficient treatment, and the switch time of circulations is prolonged. The evaporator connected with the low-pressure side in series can solvethe problem that the heat and humidity load processing capacities of the system are inconsistent.

Owner:SHANGHAI JIAO TONG UNIV

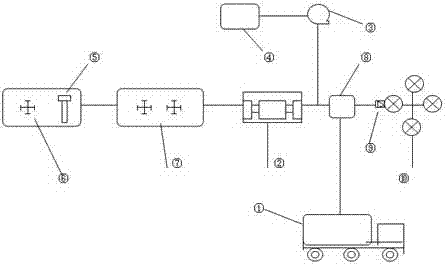

Clay foam composite system and method and device for applying clay foam composite system to oil-water well

InactiveCN106947442AAdjustable flow permeabilityAchieve steeringDrilling compositionSealing/packingSolid phasesSodium silicate

The invention relates to a clay foam composite system and a method and device for applying the clay foam composite system to an oil-water well. The clay foam composite system disclosed by the invention is prepared through uniformly mixing slurry and gas, wherein the slurry is prepared from the following ingredients: (1) sodium bentonite; (2) oil-well cement; (3) a dispersant: NaOH; (4) a foamer: sodium lauryl sulfate; (5) a stabilizer: 1) silicone amide; and 2) sodium silicate; and (6) the balance of fresh water; and the gas is nitrogen gas with the purity of not lower than 95%, the gas and the slurry are proportioned by volume, strata pressure is taken into account, and the underground gas / slurry ratio is (2: 1) to (1: 1). The clay foam composite system, the method and the device have the beneficial effects that a plugging mechanism of the composite system disclosed by the invention mainly comprises two parts, i.e., solid-phase filler plugging and gas-phase Jamin-effect plugging and has adjustable fluidity and permeability; due to solid particles, the strength of a liquid film can be enhanced; and meanwhile, an aqueous solution of the foamer in the system can be used for changing the wettability of rocks of strata on one hand and can also be used for reducing the viscosity of thick oil on the other hand, so that the fluidity of fluid of the strata is improved, and thus, the actions of reducing viscosity and helping displacement are achieved.

Owner:SHENGLI OILFIELD PETROLEUM DEV CENT +1

Carbonization repair method of volatile organic compound-heavy metal compound polluted soil

InactiveCN108672489AHigh evaporative extraction rateImprove extraction efficiencyContaminated soil reclamationResource utilizationCarbonization

The invention discloses a carbonization repair method of volatile organic compound-heavy metal compound polluted soil, and belongs to the field of polluted soil repair. The method comprises the stepsof compound polluted soil pretreatment, organic pollutant separation and extraction, curing agent mixing, granulation of polluted soil uniform mixtures, carbonization of polluted soil uniform mixed granules, storage and maintenance of carbonized polluted soil particles, waste liquid / waste gas collection, waste heat utilization and resource utilization. The heating time, the curing agent mixing quantity and the carbonization time are adjusted by actually measuring the organic matter components and concentrations of the compound polluted soil, heavy metal components and contents, temperature andthe water content, and therefore the optimal work efficiency is achieved. In the working process, volatile organic pollutants are extracted, and dust, waste gas and carbonized heavy metal are absorbed. The method is safe, rapid, low-carbon, environment-friendly and high in continuous working rate, produced carbonized polluted soil particles are high in hardness and strength and low in leaching efficiency and can be used as roadbeds, airfield runways, engineering backfill and the like, and great engineering construction significance is achieved.

Owner:NANJING FORESTRY UNIV

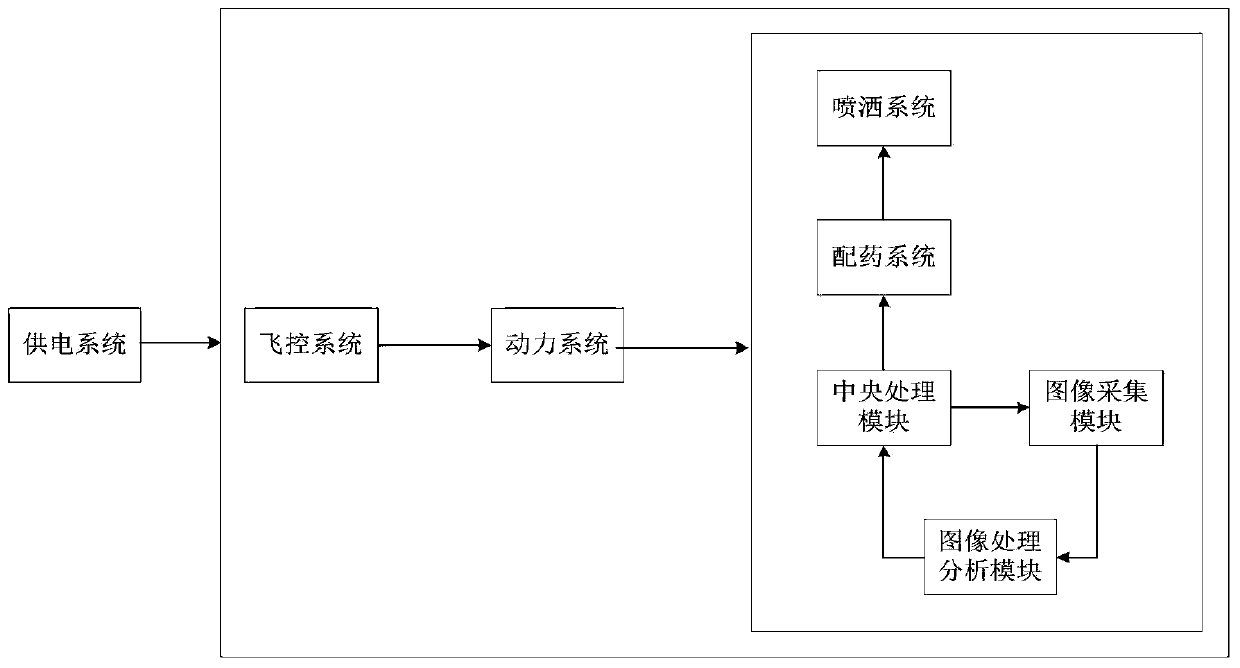

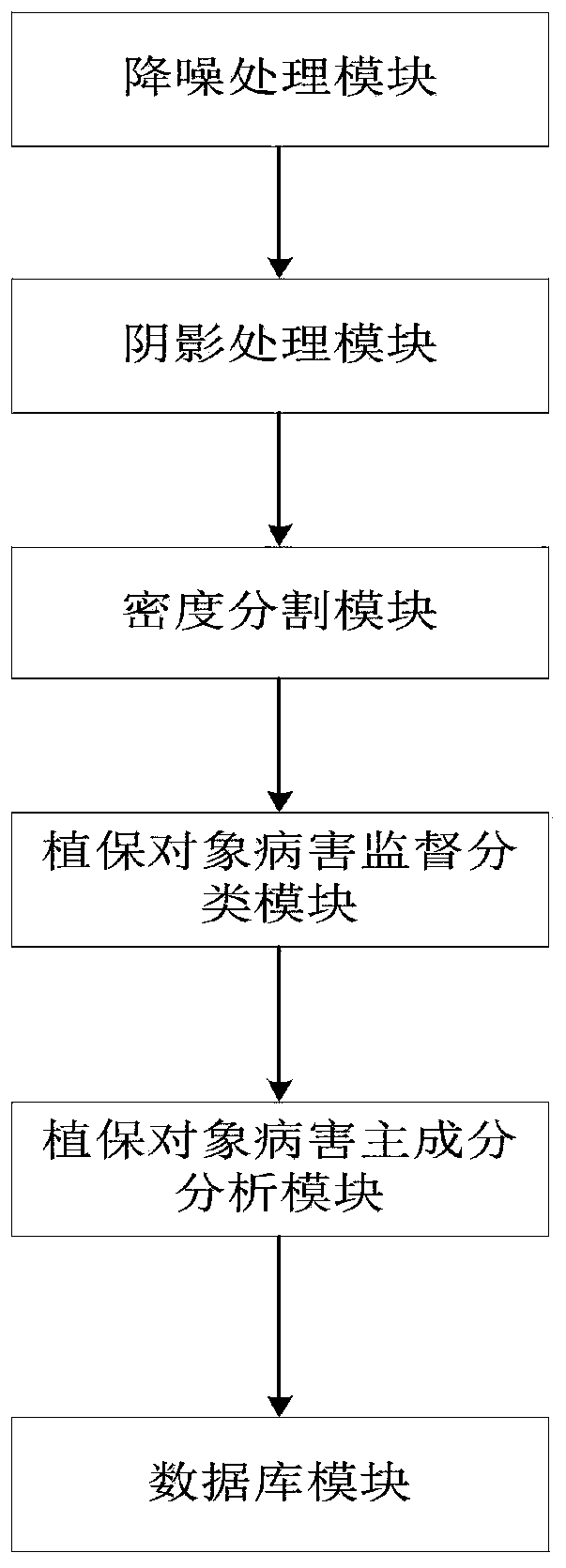

Flight control system special for plant protection unmanned aerial vehicle

PendingCN111427377AEasy to useThe ratio of medicines is flexibleAircraft componentsTransmission systemsAerospace engineeringSystems engineering

Owner:海南耐威科技系统技术研究院有限公司

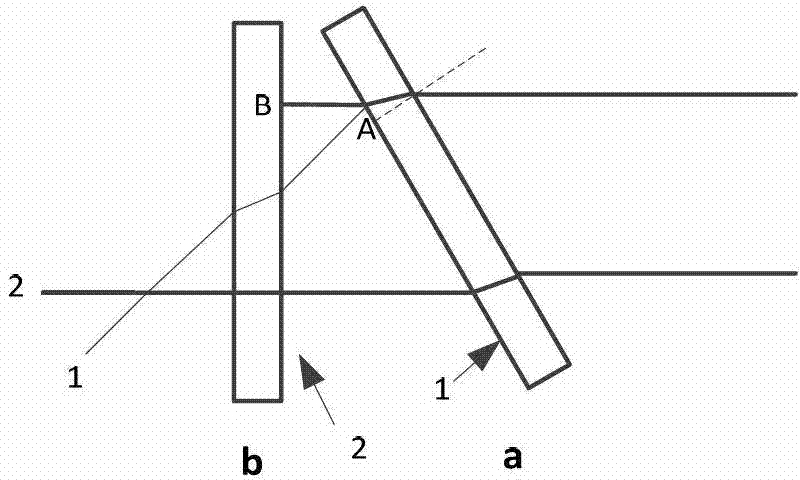

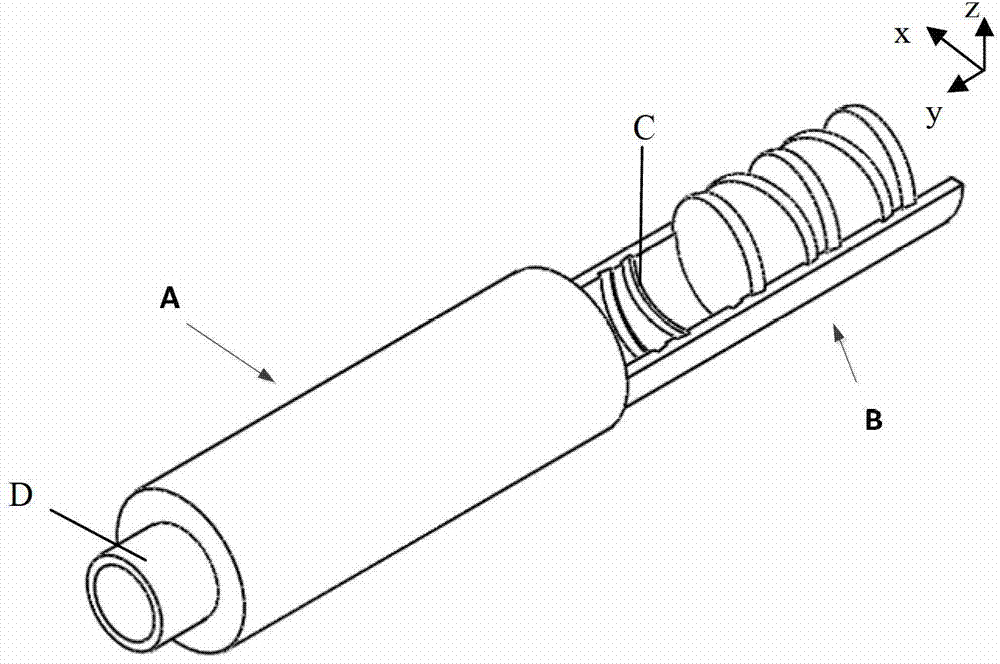

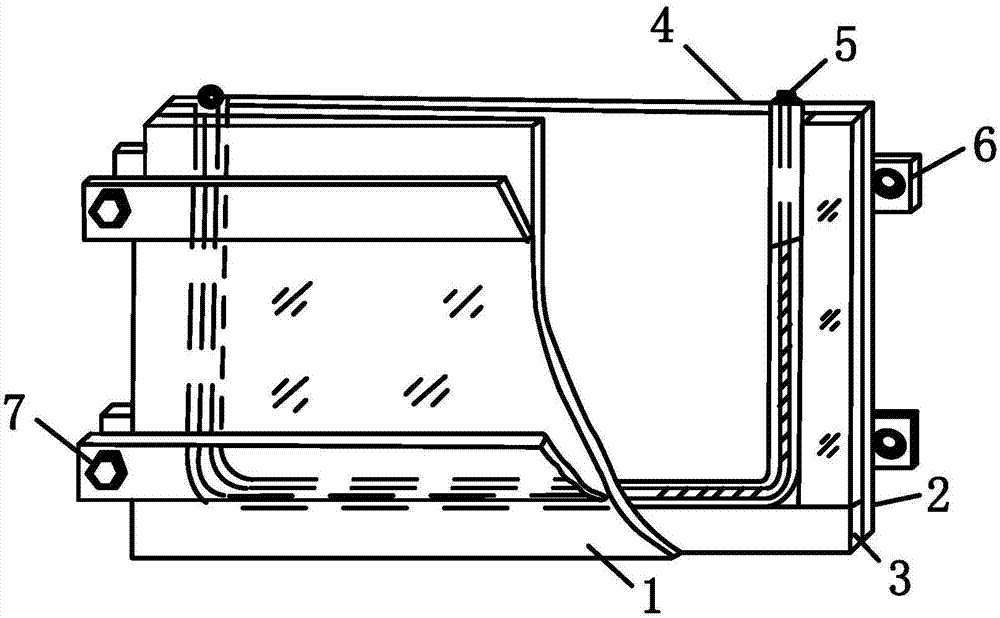

Attenuation slice placing device

InactiveCN102902032ASuppression of interference fringesFor quick replacementMountingsUltrasound attenuationEngineering

The invention provides an attenuation slice placing device which comprises an installation seat. The attenuation slice placing device is characterized in that at least two grooves for placing attenuation slices are sequentially arranged on the surface of the installation seat along the axis direction, and the grooves are inclined so that each two adjacent attenuation slices are ranked in a splayed shape after the attenuation slices are installed in the grooves. By means of the attenuation slice placing device, interference fringes generated due to exit spots of the attenuation slices are effectively inhibited, the attenuation slices can be rapidly replaced, different attenuation multiples can be flexibly and rapidly matched, the device can be conveniently matched with a charge coupled device (CCD) to form a completely sealed structure, and stray light can be shielded, backgrounds and noises brought by the stray light can be removed, so that collected spot information is accurate.

Owner:BEIJING GK LASER TECH

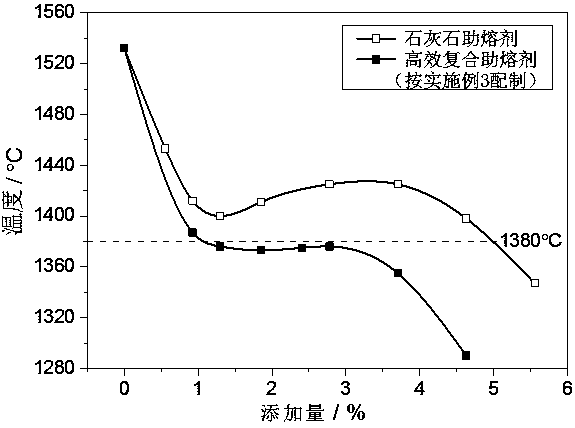

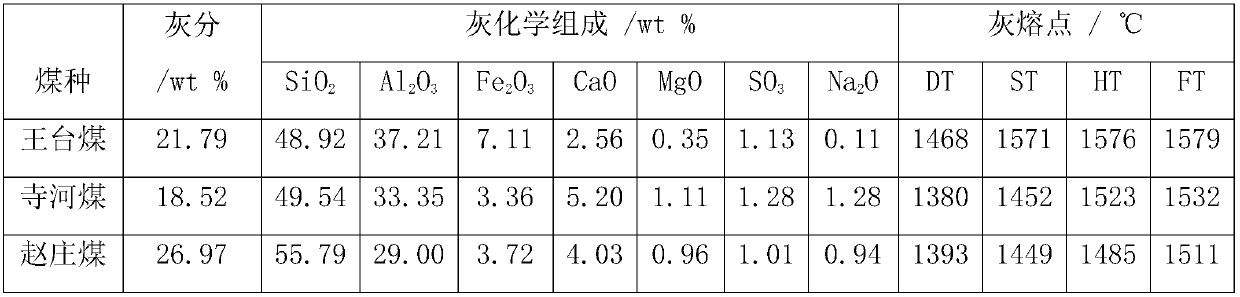

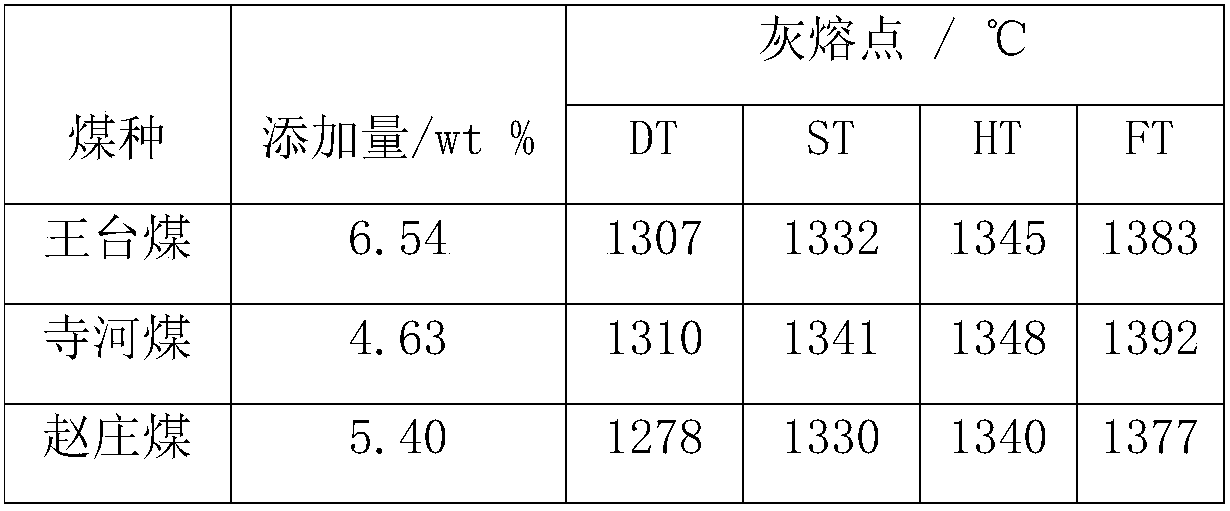

High-efficiency composite flux for lowering the melting point of coal ash and its preparation method and application

ActiveCN106520206BAdd lessImprove flux effectGasification processes detailsGranular/pulverulent flues gasificationSodium sulfateCoal

A high-efficiency composite flux for reducing the melting point of coal ash is formed by compounding calcium-containing mineral powder with sodium-containing sodium sulfate according to a ratio of 1:1 to 8:2, and mainly comprises, by mass, 48.2-79.4% of CaCO3, 19.7-49.5% of Na2SO4 and 0.2-0.7% of CaO. The high-efficiency composite flux has the advantages of small addition amount, low cost, and reduction of the melting point of the coal ash.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

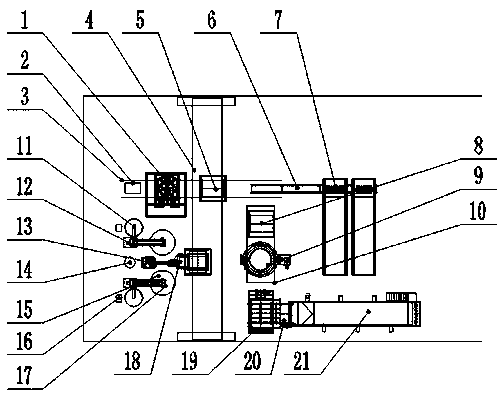

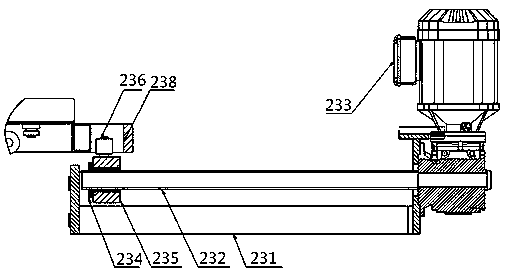

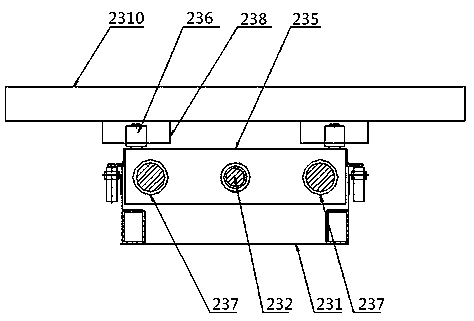

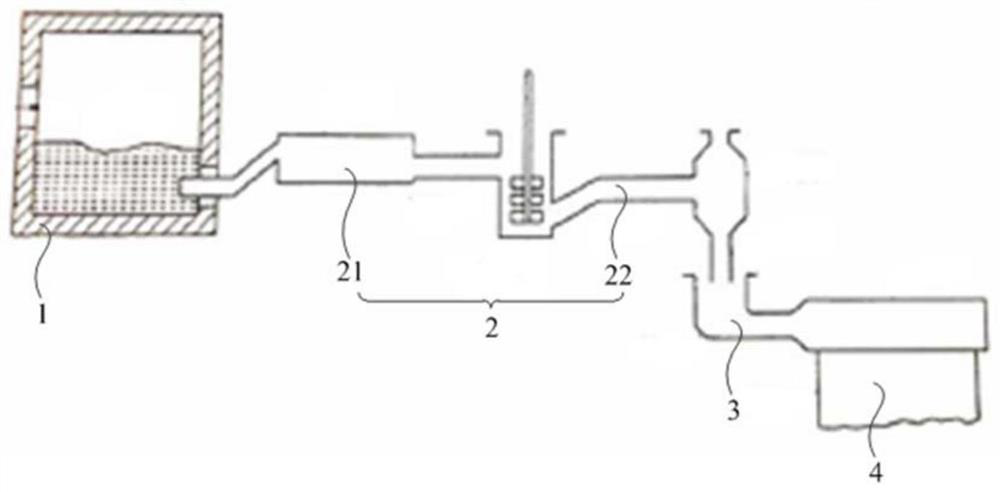

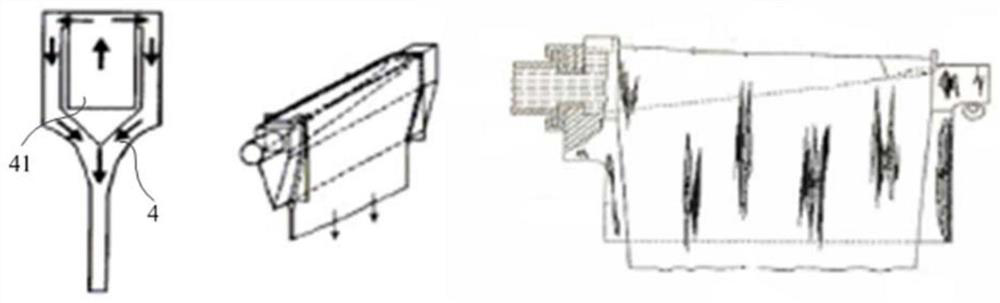

Automatic production system for brewing of liquor

PendingCN108913423AReduce complexityLow operating and maintenance costsAlcoholic beverage preparationDistillationBran

The invention discloses an automatic production system for brewing of liquor. The automatic brewing system is composed of a batching unit, an intelligent travelling crane, an integral mixing unit, anautomatic rice steamer charging unit, a distillation unit and an airing unit. According to the invention, mechanical automation of the whole liquor brewing process is realized, the influence of artificial factors is eliminated, and the quality consistency of liquor is guaranteed; all the constituent equipment of the system is simple to install and debug, so the production cost for automatic liquorbrewage is lowered, and the installation period of the liquor brewage production system is shortened; the intelligent travelling crane is utilized as a main transfer body for the automatic brewing system, so the complexity of the automatic brewing system is greatly reduced, and the operation and maintenance cost of the automatic brewing system is lowered; and a vinasse hopper separately receivesvinasse, grains and bran in virtue of a vinasse hopper shifting machine, and the vinasse, grains and bran are concentratedly proportioned and enter the vinasse hopper in one shot, so material proportions are guaranteed, the proportioning of the vinasse, grains and bran is flexible, requirements for different process proportioning parameters can be met, and the system has good compatibility.

Owner:LUZHOU ZHITONG AUTOMATION EQUIP CO LTD

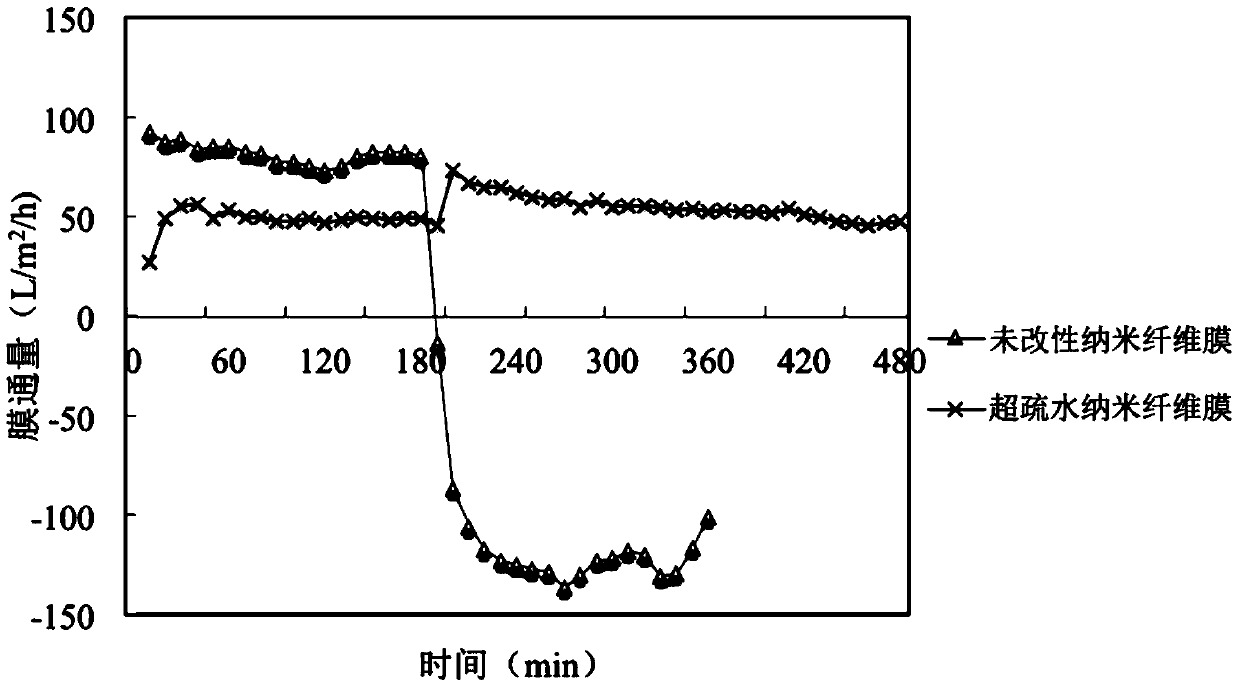

A kind of preparation method and application of superhydrophobic film

The invention provides a preparation method of a super-hydrophobic membrane. The preparation method comprises steps as follows: hydrophobic organic polymer materials and nano granules are dissolved in an organic solvent, the mixture is stirred and left to stand, and an electrostatic spinning solution is prepared; high-pressure electrostatic spinning parameters are set, electrostatic spinning membrane preparation is performed, and a nanofiber membrane is obtained and subjected to thermal treatment; TiO2 is prepared, the surface of the nanofiber membrane is covered with TiO2, and thermal treatment, water-bath heating, washing and ultraviolet radiation treatment are performed; silane solutions are prepared, the nanofiber membrane surface covered with TiO2 is covered with the silane solutions, thermal treatment, washing and airing are performed, and the super-hydrophobic membrane is obtained. The invention further provides an application of the super-hydrophobic membrane in the membrane distillation process. By means of the method, the super-hydrophobic nanofiber membrane is prepared. The membrane simultaneously has super-hydrophobicity and high throughput performance, the wet resistance of the membrane is effectively improved, and the service life of the membrane is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

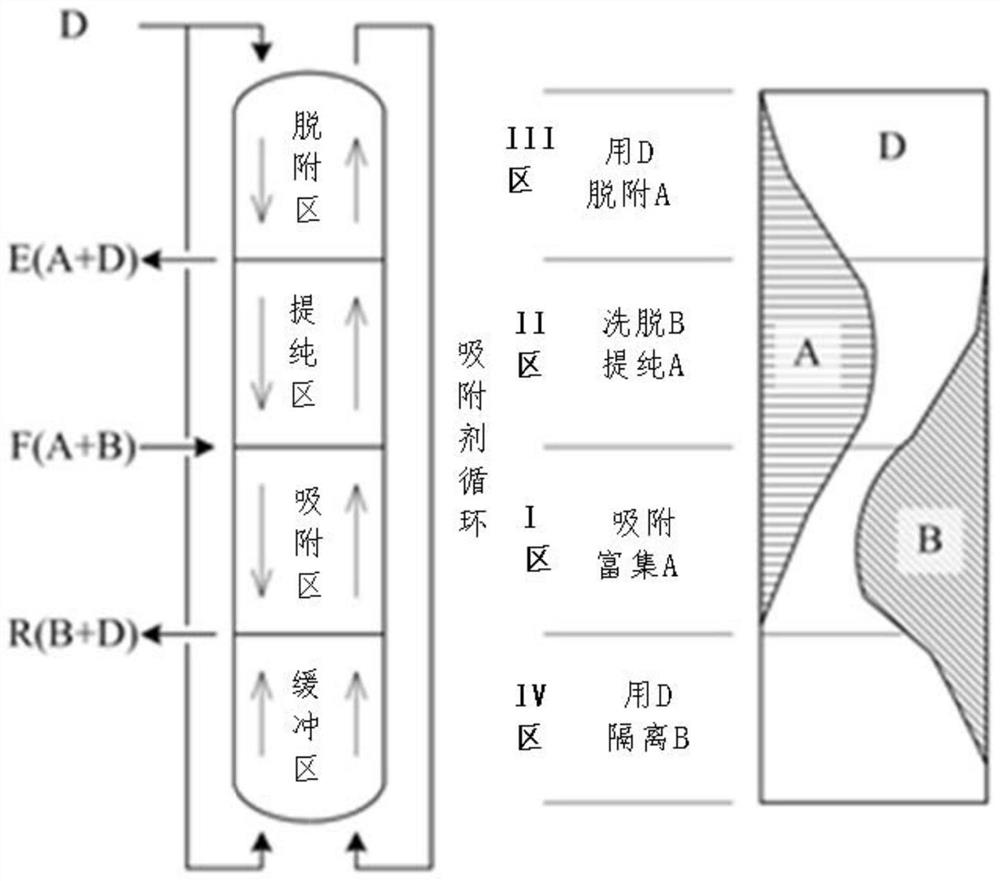

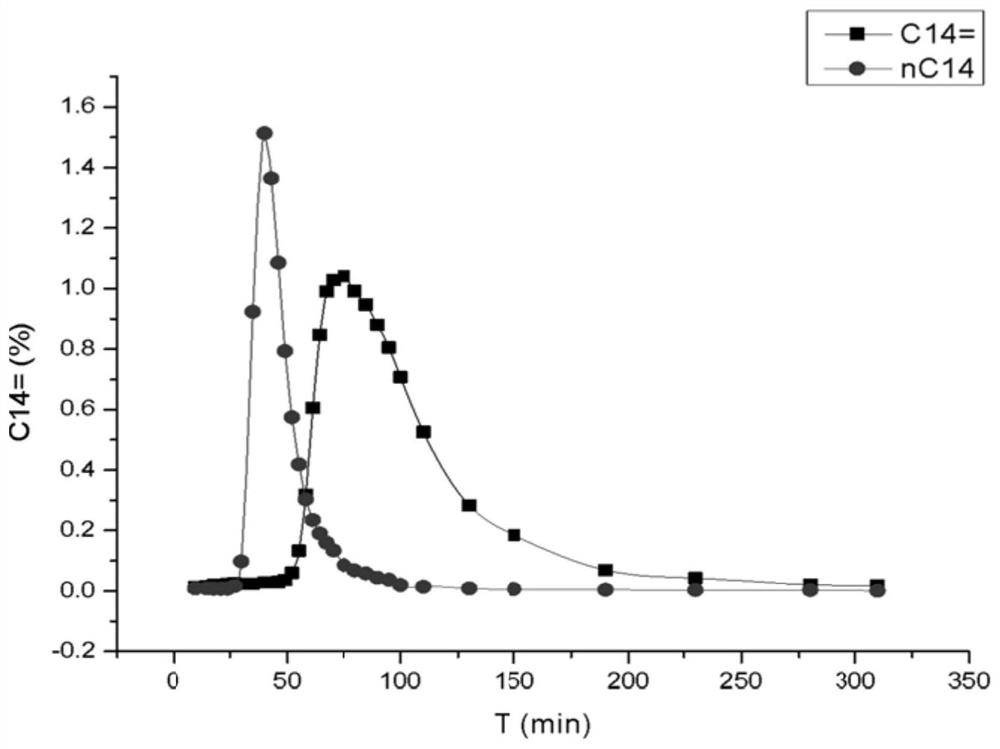

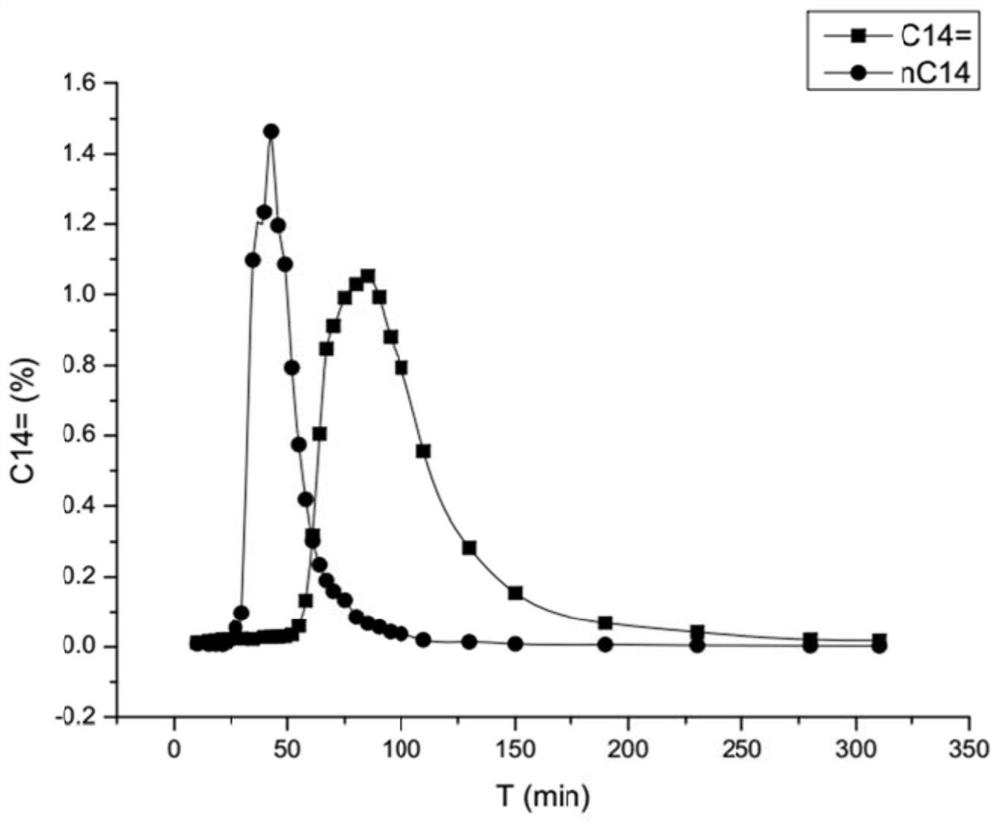

Method for separating alkane and olefin by using simulated moving bed

PendingCN113087587AFlexible ratioCheap and easy to getAdsorption purification/separationAlkaneCarbon number

The invention provides a method for separating alkane and olefin by using a simulated moving bed. The method comprises the following steps: eluting by using an eluent, wherein the eluent is n-alkanes, and the difference between the carbon number of the n-alkanes and the carbon number of olefins in a raw material to be separated is greater than 1 and less than 7 (e.g., 2, 3, 4, 5 or 6), preferably greater than 1 and less than 5 (e.g., 2, 3 or 4). The eluent can reduce the cost and improve the product recovery rate.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

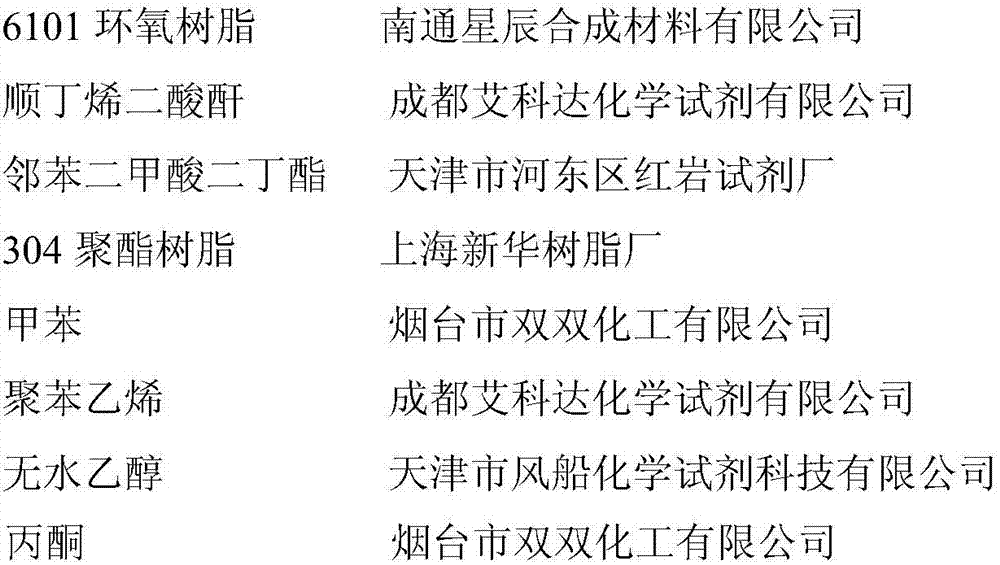

Production method of epoxy resin board for photo-elastic experimental test

InactiveCN106928657AFlexible ratioPerformance tuningForce measurement by measuring optical property variationEpoxyPolyester resin

The invention discloses a production method of an epoxy resin plate used for photoelastic experiment testing. The method uses epoxy resin, maleic anhydride, dibutyl phthalate and polyester resin as raw materials. Epoxy resin boards with different properties can be prepared by adjusting the amount of raw materials and optimizing the curing process of the mixed raw materials. The method of the invention is simple, rich in raw materials, easy to produce, high in optical sensitivity, good in transparency, small in time edge effect, and capable of producing novel photoelastic epoxy resins with elastic modulus from 1.29MPa to 57.32MPa and Poisson's ratio from 0.35 to 0.68 It can be used to make structural similar models in mechanical, water conservancy, civil engineering and other engineering, and it is an excellent material for photoelastic experiments of plane stress models.

Owner:HENAN POLYTECHNIC UNIV

A 3D additive T-shaped structure double-sided laser welding method

ActiveCN105710536BImprove mechanical propertiesEvenly regulatedLaser beam welding apparatusLight beamAlloy

The invention provides a 3D additive-manufacturing bilateral laser welding method for a T-shaped structure, relates to a double-laser-beam welding method, and aims to solve the problems that under the conditions of high welding speed and long weld beads, in a bilateral laser welding process of a T-shaped structure, the circumstance that welding wires are continuously and stably fed into a molten pool at constant speed and even, coherent and non-defective bilateral weld joints are obtained by one-time welding is difficult to ensure, and alloy of weld microstructures is difficult to regulate and control specifically and flexibly. The method comprises the following steps: 1, chemically cleaning the surface of a stringer; 2, designing of a sedimentary layer: designing the sedimentary layer in a region to be welded on the surface of the stringer, wherein the cross section of the sedimentary layer is square or rectangular; 3, vertically placing a laser cladding head at a position right above the region to be welded on the surface of the stringer, carrying out laser 3D additive-manufacturing on regions to be welded on two sides of the stringer to obtain the sedimentary layer in a mode of coaxially feeding laser beams and alloy powder; and 4, carrying out bilateral laser welding on the stringer and an envelope to obtain bilateral symmetric weld joints. The 3D additive-manufacturing bilateral laser welding method for the T-shaped structure is used for double-laser welding of the T-shaped structure.

Owner:HARBIN INST OF TECH

Fire fighting method

InactiveCN108343465AAvoid it happening againInhibit sheddingDust removalFire preventionCombustionEngineering

The invention relates to the field of fire fighting, in particular to a fire fighting method. The fire fighting method comprises the following steps that a setting accelerator is mixed with 5-15% of ablender by mass, then mixed with a first mixture of water glass compounds, a clarifying agent and the rest of the blender, and then injected. The fire fighting method is high in maneuverability, flexible, practical, and capable of treating point-shaped and small-space treating coal self-combustion disasters which are not suitable for being put out by water and achieving safe, rapid and effectivefire fighting effects.

Owner:INNER MONGOLIA YITAI COAL

A double-sided laser welding method controlled by powder metallurgy

ActiveCN105728944BImprove mechanical propertiesEvenly regulatedVehicle componentsMetal working apparatusAlloyLaser beams

The invention discloses a double-side laser welding method for powder metallurgy control, relates to a double-laser beam welding method, and solves the problem that welding wire elements cannot perform full alloy control for a welding line structure in the double-side laser welding process of a T-shaped structure. The method comprises the following steps: (1) a groove is mechanically milled in the center of a position to be welded on the upper surface of a cover in the welding direction; and the cover is chemically cleaned to remove an oxide film and machining stains; (2) alloy powder is prefilled in the groove to form a deposition layer; a laser cladding head is vertically placed rightly above the groove; the laser powder feeding material adding is performed on the surface of the groove to obtain the deposition layer by using a mode of coaxial feeding of laser beams and the alloy powder; and a deposition material higher than the surface of the cover is grinded off by using a grinding machine, so that a deposition surface is coplanar with the surface of the cover; and (3) the double-laser wire filling welding is performed for a long purlin and the cover to obtain symmetric welding lines on two sides. The method is used for double-laser beam welding of the T-shaped structure.

Owner:HARBIN INST OF TECH

Glass, glass forming method, pressing device and calender

PendingCN112777930AHigh optical clarityImprove flexural strengthGlass rolling apparatusBar pressingGlass forming

The invention relates to glass, a glass forming method, a pressing device and a calender. The glass is prepared by a calendaring molding method; the glass is prepared from the following raw materials: SiO2, Li2O, Na2O, CaO, MgO, Al2O3 and TiO2+ZrO2; the pressing device comprises two pressing mechanisms which are oppositely arranged, each pressing mechanism comprises a base, a cross beam, a pressing rod, a stand column and a driving mechanism, the stand columns and the driving mechanisms are installed on the bases, the first ends of the pressing rods, the ends, away from the bases, of the stand columns and the ends, away from the bases, of the driving mechanisms are all pivoted to the cross beams, and the stand columns are located between the pressing rods and the driving mechanisms; the calender comprises the pressing mechanism. The glass provided by the invention has relatively good performance and relatively high mechanical strength.

Owner:SIPING HONGDA HYDRAULIC MECHANICAL MFG CO LTD

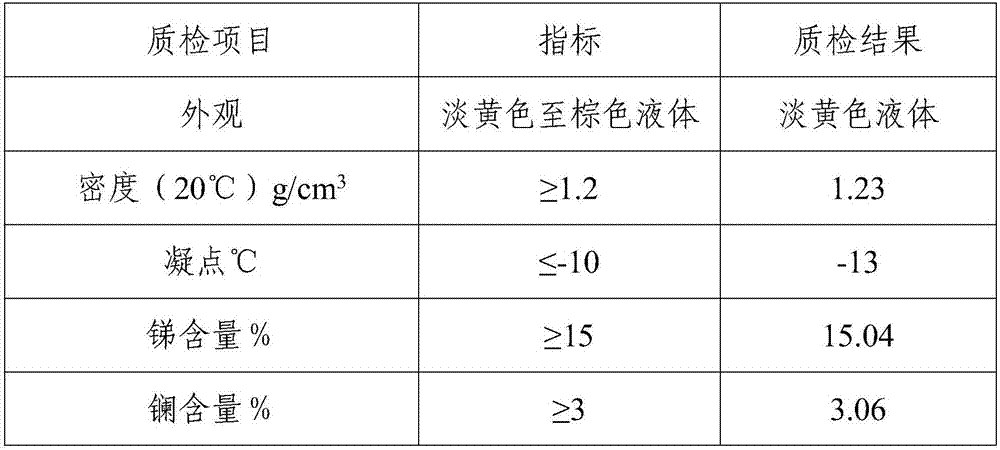

Multi-metal deactivator for catalytic device of refinery plant and preparation method thereof

InactiveCN107159315AImprove microreactivityImprove hydrolysis resistanceCatalytic crackingCatalyst protectionAntimony trioxideLanthanum

The invention provides a multi-metal deactivator for a catalytic device of a refinery plant and a preparation method thereof. An agent A and an agent B at the mass ratio of 1:(0.2-0.3) are compounded into the multi-metal deactivator; the agent A comprises antimonous oxide, triethylamine, tartaric acid, hydrogen peroxide and deionized water; and the agent B comprises lanthanum acetate, glacial acetic acid and deionized water. Reasonable compound ratio is adopted for the poison of the metal, such as, nickel and vanadium in the raw materials of the refinery plant to the splitting catalyst according to the invention, the hydrogen methane ratio is reduced while the micro-activity of the catalyst is promoted, the deactivating effect is effectively improved, the technical efficiency is promoted, the preparation technology is simple and convenient, the matching ratio is flexible and the applicability is high.

Owner:安徽卓远化工科技有限公司

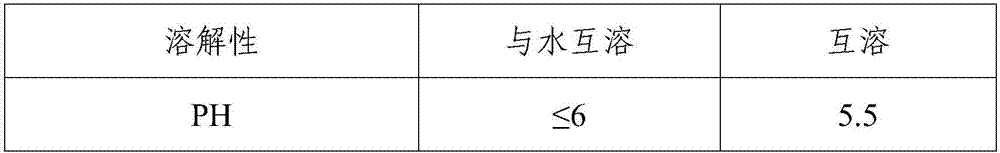

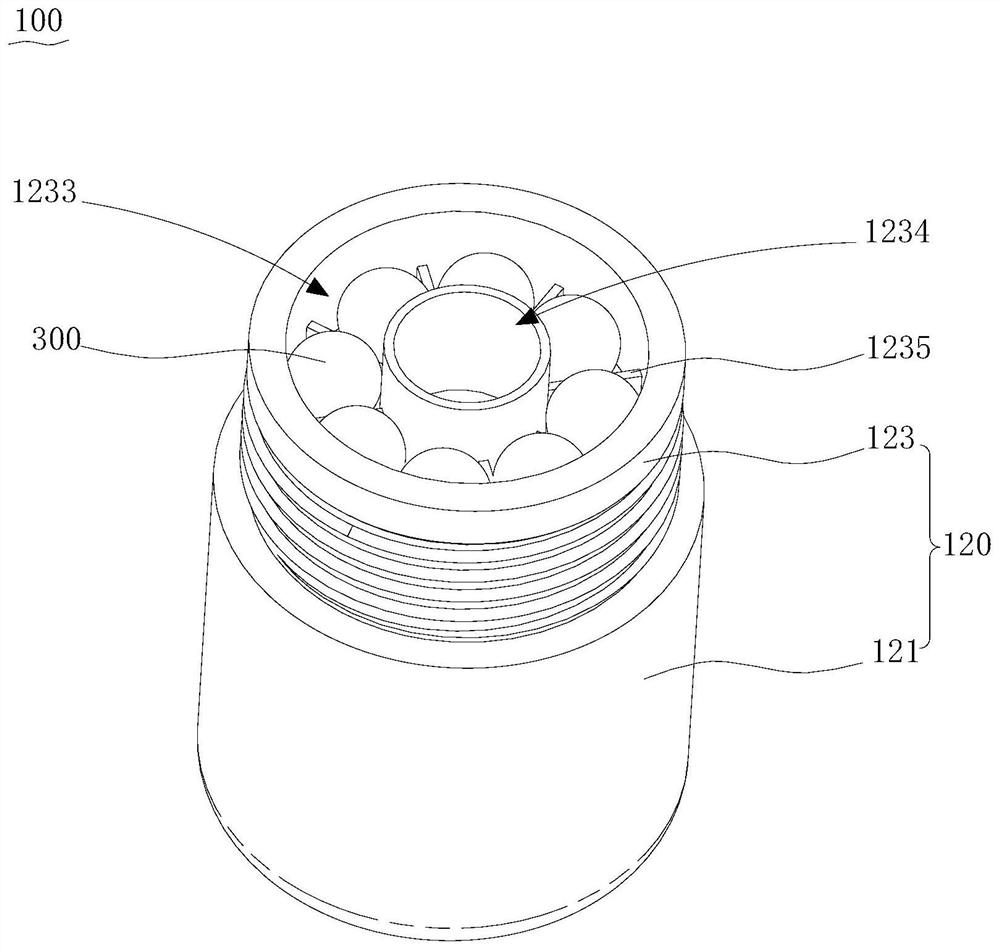

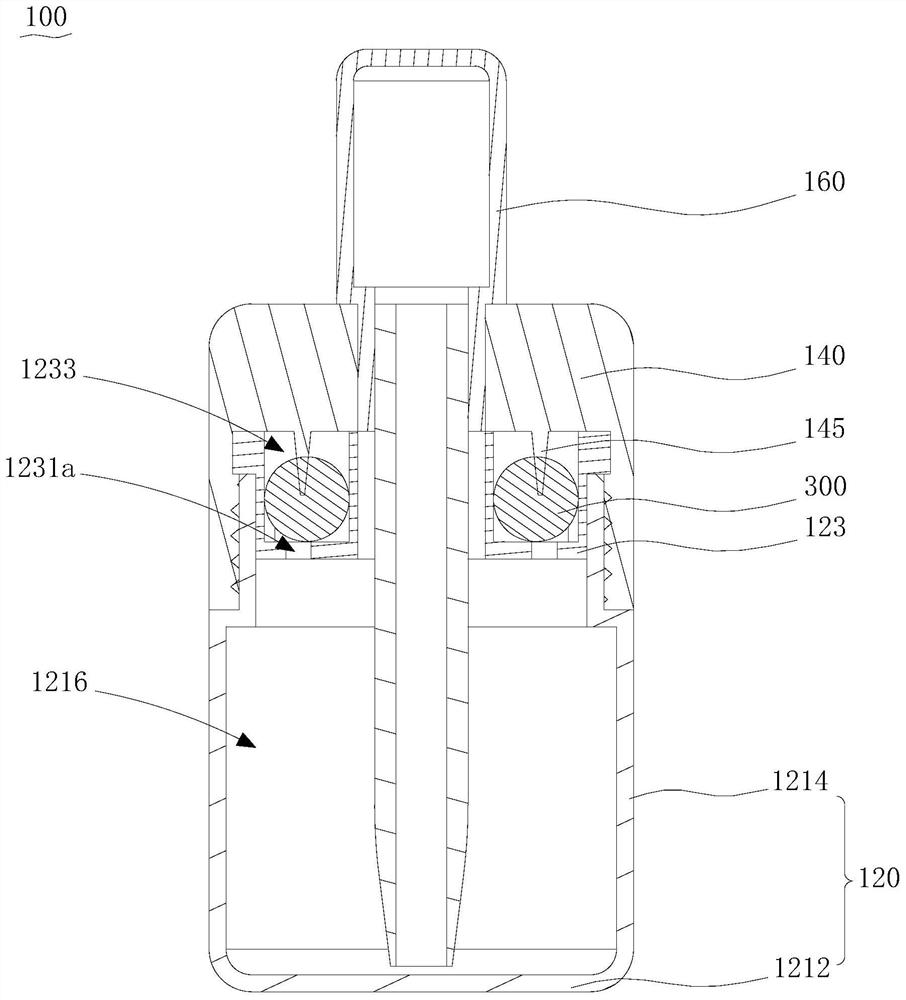

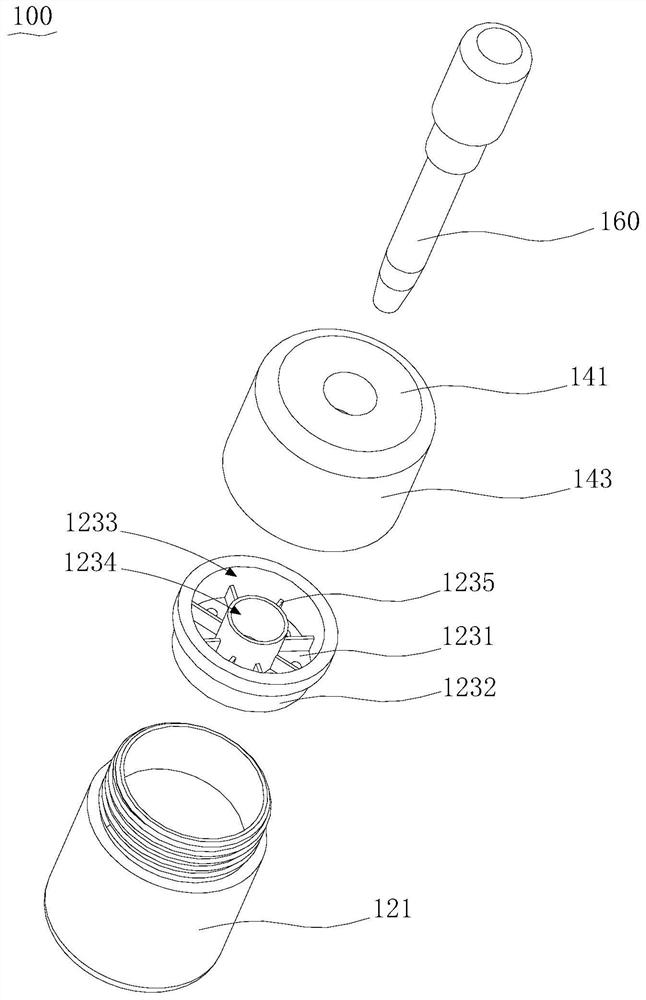

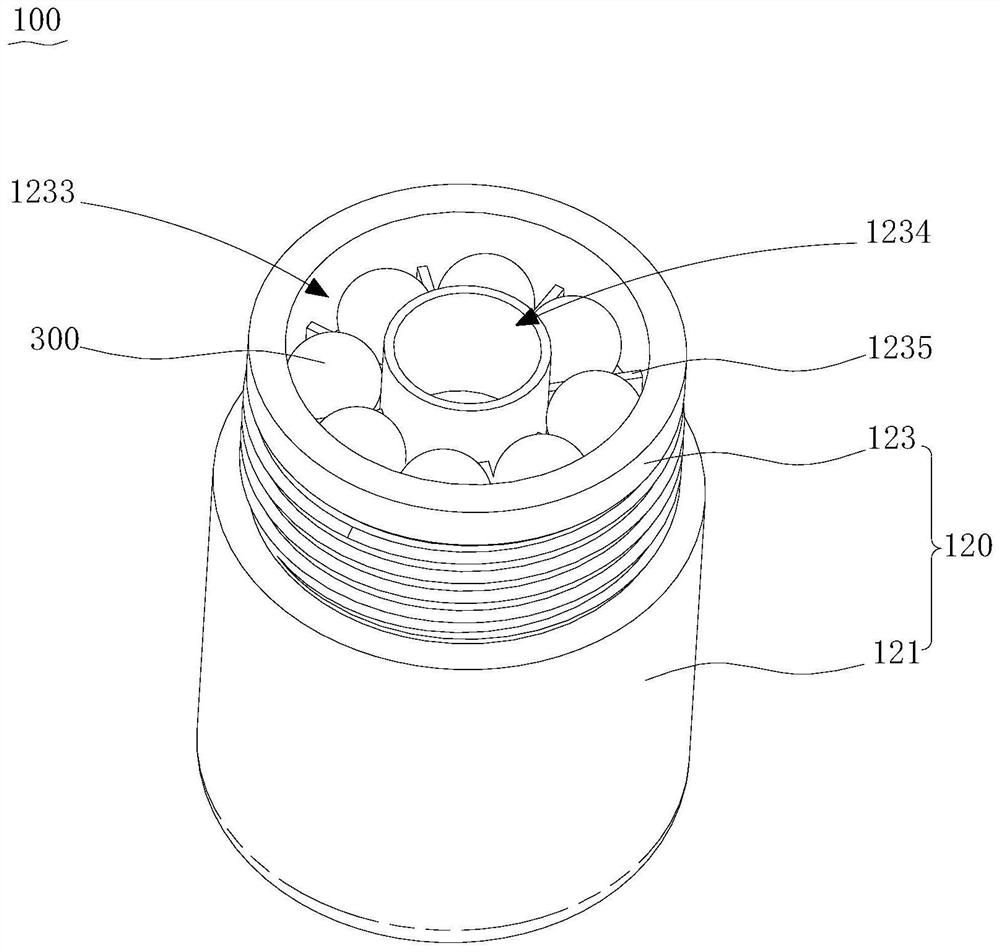

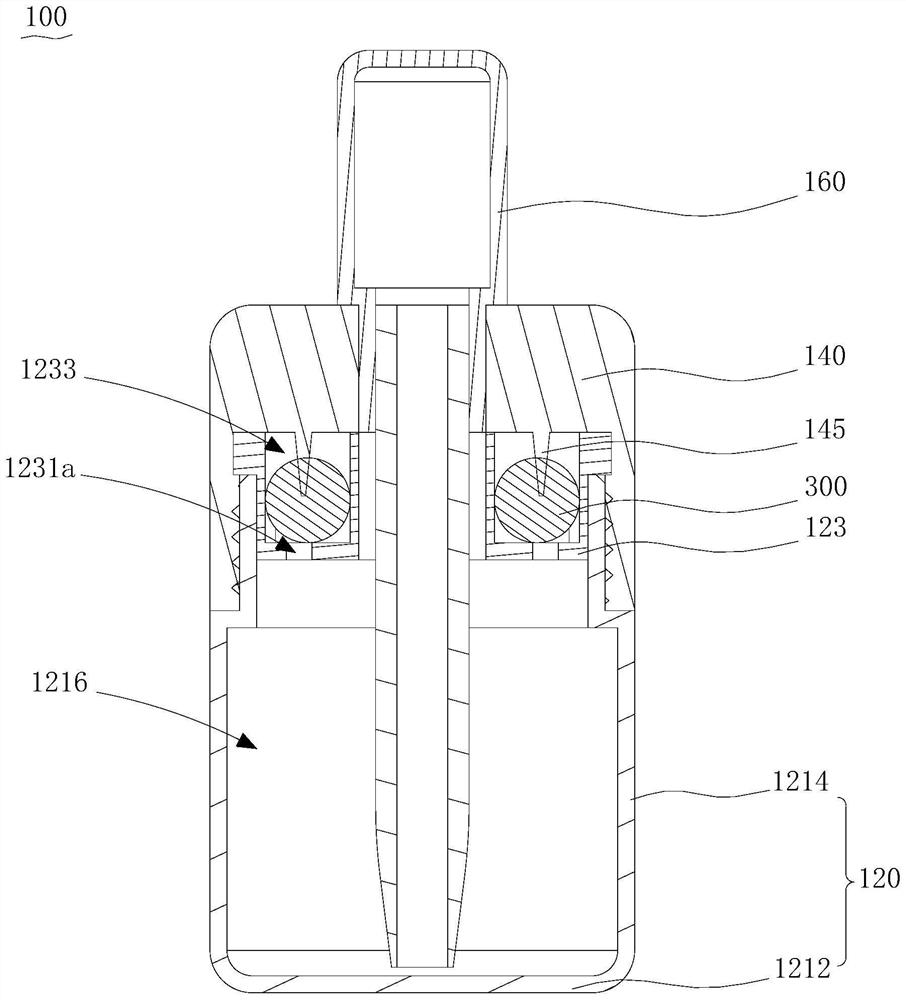

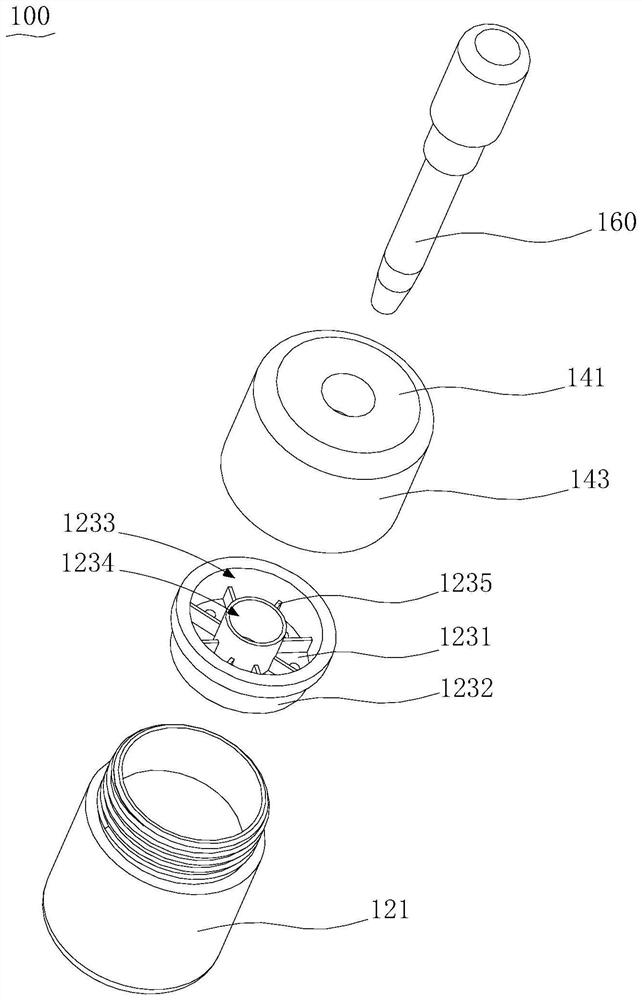

Atomized liquid storage device

ActiveCN111942753AMeet different needsFlexible ratioClosure with auxillary devicesMixersEngineeringPhysics

The invention relates to an atomized liquid storage device. The device comprises a main housing and a mixing cover. The main housing comprises a main containing cavity and an auxiliary containing cavity which are communicated with each other, the main containing cavity is used for containing atomized liquid, and the auxiliary containing cavity is used for containing a unit to be blended; and the mixing cover is detachably connected to the main housing in a matched manner, and the mixing cover is provided with a crushing piece. When the mixing cover is connected to the main housing in the matched manner, the crushing piece stretches into the auxiliary containing cavity so as to crush the unit to be blended. According to the atomized liquid storage device, a user can select different units to be blended to be placed in the auxiliary containing cavity, when the mixing cover is connected to the main housing in the matched manner, the crushing piece on the mixing cover stretches into the auxiliary containing cavity to crush the units to be blended, and the crushed units to be blended release materials to be blended into the main containing cavity to be mixed with atomized liquid, so that different materials are flexibly proportioned to adjust the components of the atomized liquid, and different requirements of users are met.

Owner:镁乐生物科技(深圳)有限公司

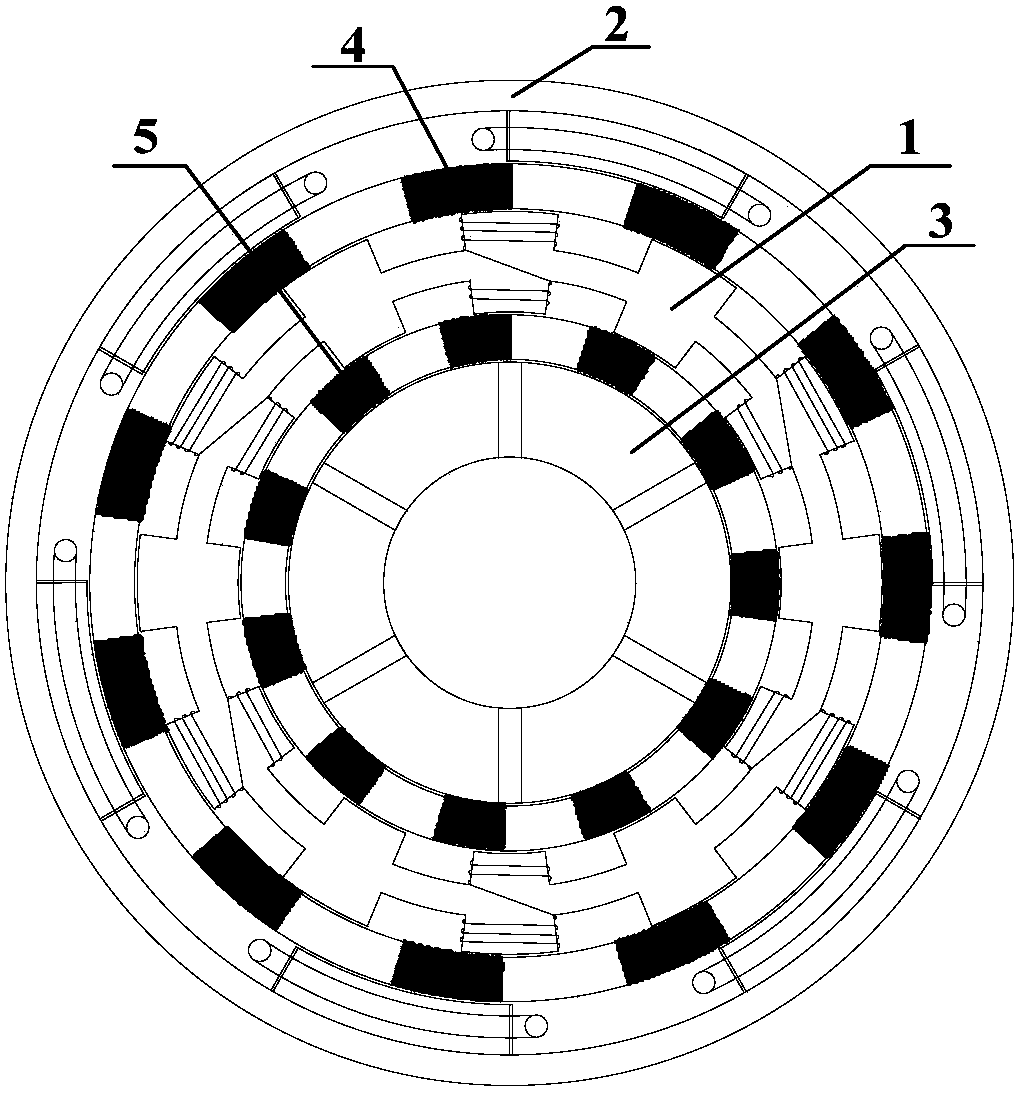

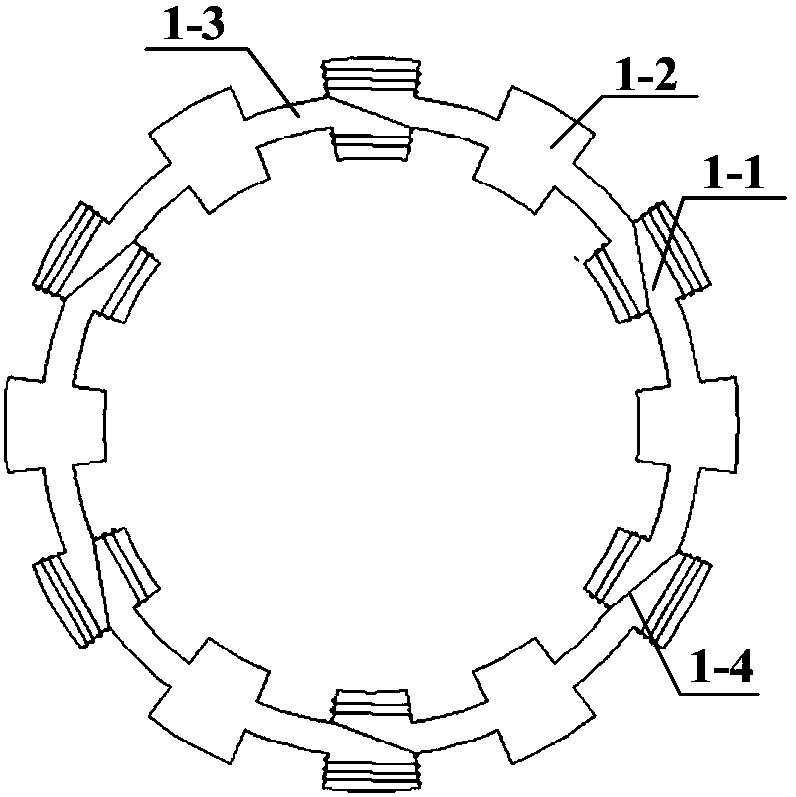

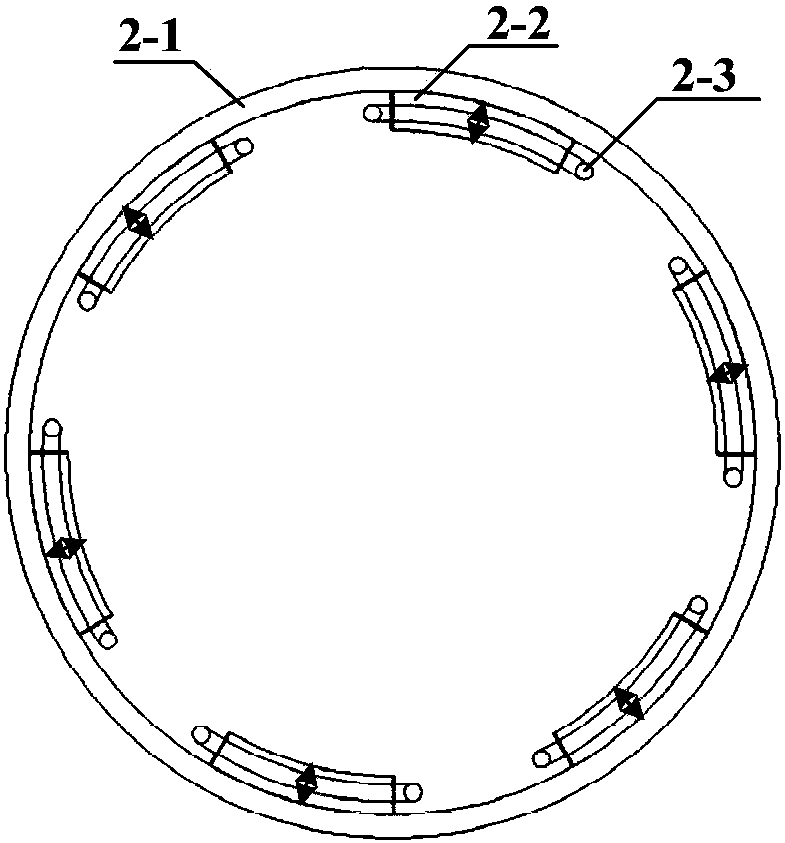

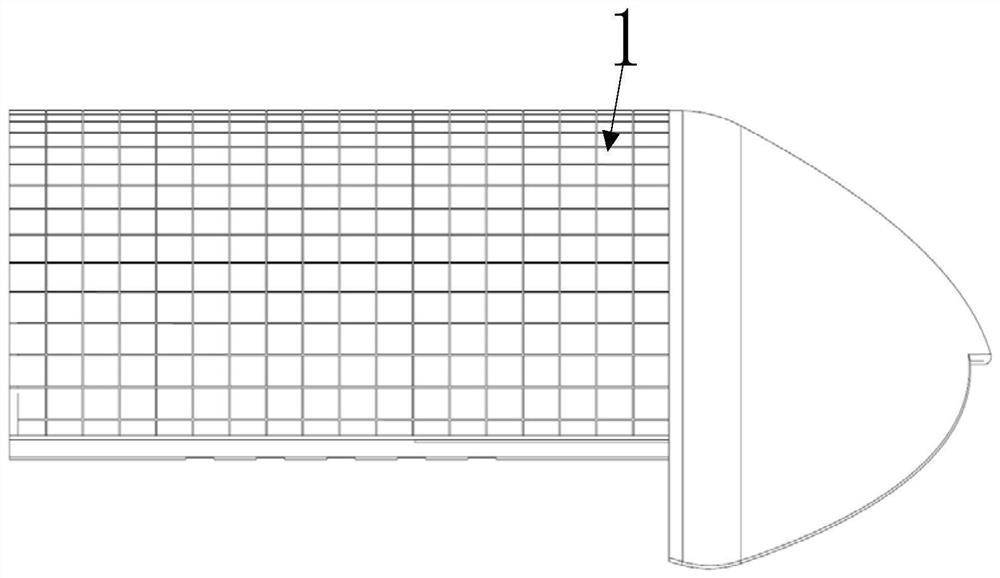

A rare-earth combined excitation type stator-rotor dual-section adjustable flux permanent magnet motor

ActiveCN105914979BSolve the problem of mutual limitation of dosageReduce dosageSynchronous machine detailsRare earthConductive materials

The invention discloses a rare-earth combined excitation type stator-rotor dual-section adjustable flux permanent magnet motor. zone rotor and inner zone stator; the doubly salient pole middle zone stator is composed of stator yoke, stator slot, radially bilaterally protruding stator teeth and fault-tolerant teeth, among which, centralized distributed three-phase armature windings are wound on the stator teeth; the inner zone In the stator, tangentially magnetized rare earth NdFeB permanent magnets are evenly embedded along the circumferential direction; in the outer stator, radially magnetized AlNiCo permanent magnets are evenly surface-mounted along the circumferential direction, and the adjacent AlNiCo permanent magnets Slots are left between them for placing pulse magnetized windings; both the inner and outer rotors exhibit a salient pole structure, and the gaps between the salient poles are filled with non-magnetic materials. The present invention realizes the purpose of increasing the torque density, widening the speed regulation range and further reducing the usage amount of the rare earth permanent magnet material by adopting the double partition structure of the stator and the rotor.

Owner:YANGZHOU UNIV

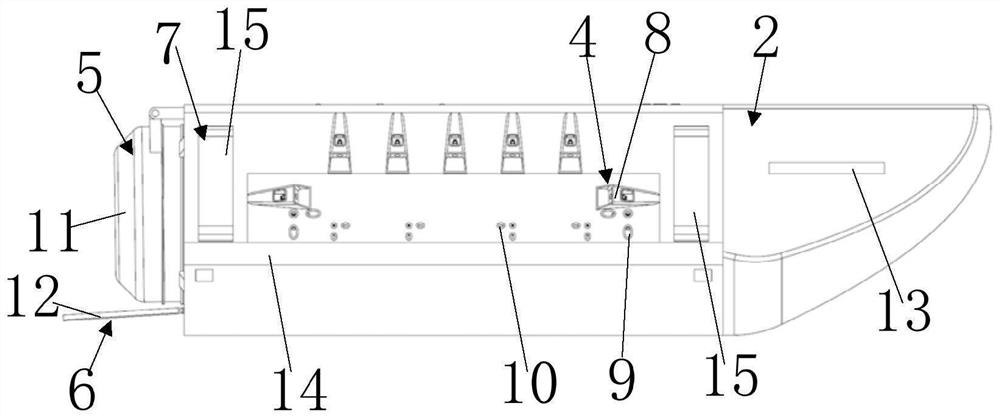

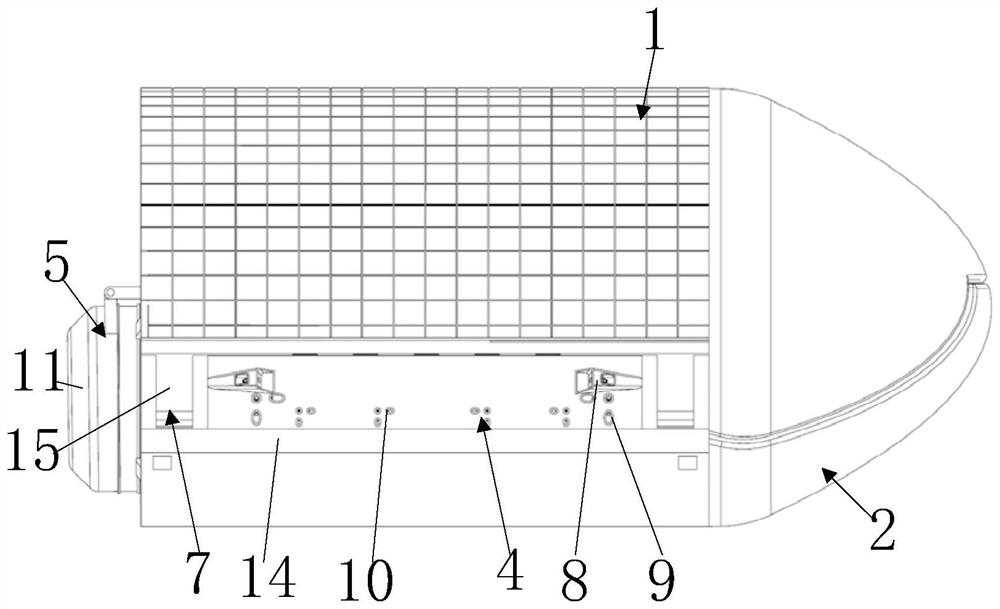

Freight spaceship for space station cargo transportation and freight method

ActiveCN114408217ALow costReduce Freight CostsCosmonautic vehiclesSystems for re-entry to earthFlight vehicleButt joint

The invention provides a freight spaceship for space station cargo transportation and a freight method. The freight spaceship for space station cargo transportation comprises a cargo hold, an aircraft, a flange butt-joint mechanical locking mechanism, a power system, a space station butt-joint mechanism, a pneumatic control flap and a landing recovery mechanism, and the flange butt-joint mechanical locking mechanism is installed on the butt-joint face of the aircraft and the cargo hold; the cargo hold is detachably installed on the butt joint face of the aircraft through the flange butt joint mechanical locking mechanism, the power system, the space station butt joint mechanism, the pneumatic control flap and the landing recovery mechanism are all installed in the aircraft, and the power system and the landing recovery mechanism are installed on the side wall of the aircraft. The space station docking mechanism is installed at the tail of the aircraft, and the pneumatic control flaps are correspondingly installed at the head and the tail of the aircraft.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Atomized liquid storage device

ActiveCN111942753BMeet different needsFlexible ratioClosure with auxillary devicesMixersProcess engineeringIndustrial engineering

The present invention relates to an atomized liquid storage device, comprising: a main housing, including a main accommodation chamber and an auxiliary accommodation chamber communicated with each other, the main accommodation chamber is used to accommodate the atomized liquid, and the auxiliary accommodation chamber is used to accommodate units to be prepared; and The mixing cover is detachably connected to the main casing, and the mixing cover is provided with a crushing part; wherein, when the mixing cover is connected to the main casing, the crushing part extends into the secondary accommodation chamber to crush the unit to be prepared. In the above-mentioned atomized liquid storage device, the user can select different units to be prepared and put them into the auxiliary storage chamber. When the mixing cover is connected to the main housing, the broken parts on the mixing cover will protrude into the auxiliary storage chamber to be broken. The blending unit releases the crushed unit to be blended into the main chamber to mix with the atomized liquid, so as to realize the flexible ratio of different materials to adjust the composition of the atomized liquid to meet the different needs of users.

Owner:镁乐生物科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com