Automatic production system for brewing of liquor

A production system and liquor technology, applied in the field of brewing, can solve the problems of high maintenance costs in the later stage of equipment, complicated equipment installation and debugging, and difficult equipment cleaning, so as to improve the workshop brewing environment, reduce operation and maintenance costs, and shorten the installation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

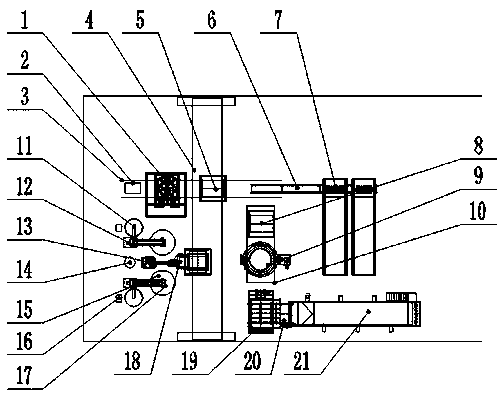

[0073] like figure 1 As shown, the liquor brewing automatic production system of the present invention is composed of a batching unit, an intelligent crane, an integral mixing unit, an automatic steamer unit, a distillation unit and an air-drying unit that cooperate with each other.

[0074] Specifically, the batching unit includes a hopper 5, a grain moistening machine 1, a chaff hopper 2 and a hopper shifter 3, the hopper 5 is placed on the hopper shifter 3, and the hopper The bucket shifter 3 is installed below the grain moistening machine 1 and the bran adding bucket 2; the grain is quantitatively input to the grain moistening machine through the metering device, the bran is quantitatively added to the bran hopper through the metering device, and the grain is quantitatively conveyed through the quantitative conveyor To the hopper, the hopper is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com