Method for separating alkane and olefin by using simulated moving bed

A technology for simulating moving bed and olefins, applied in adsorption purification/separation, organic chemistry, etc., can solve the problems of large amount of eluent, high cost of eluent, long separation time, etc. cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

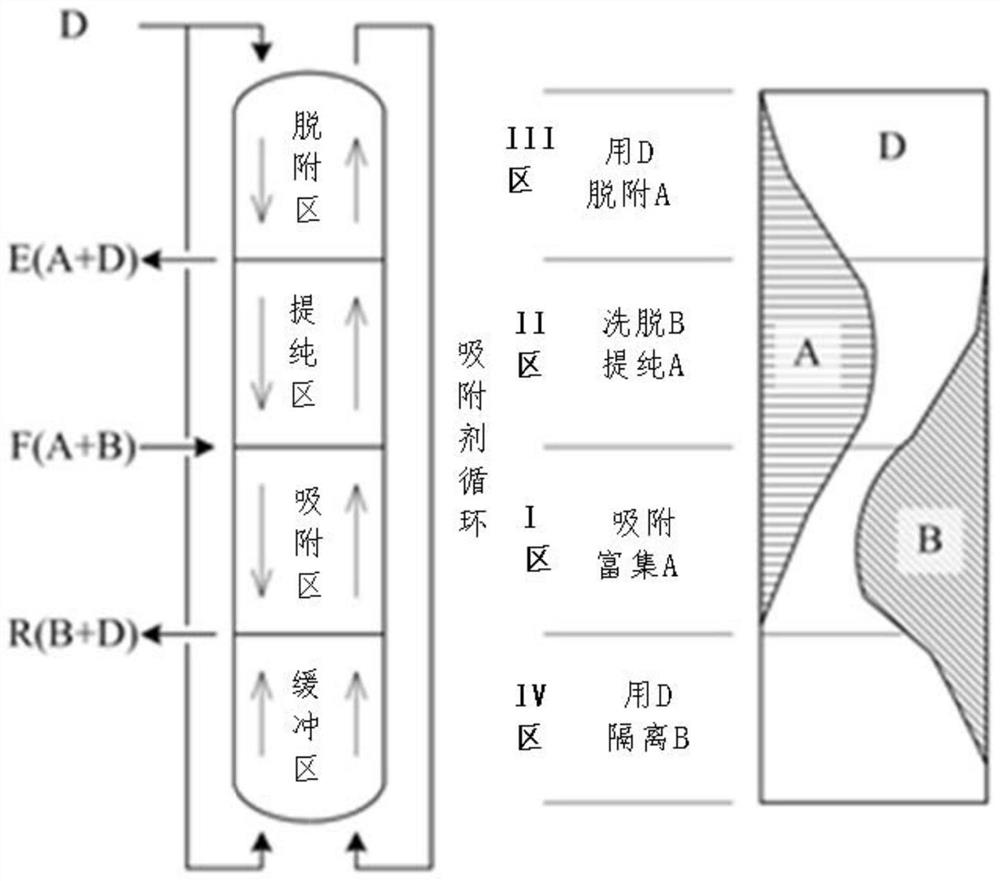

Method used

Image

Examples

Embodiment 1

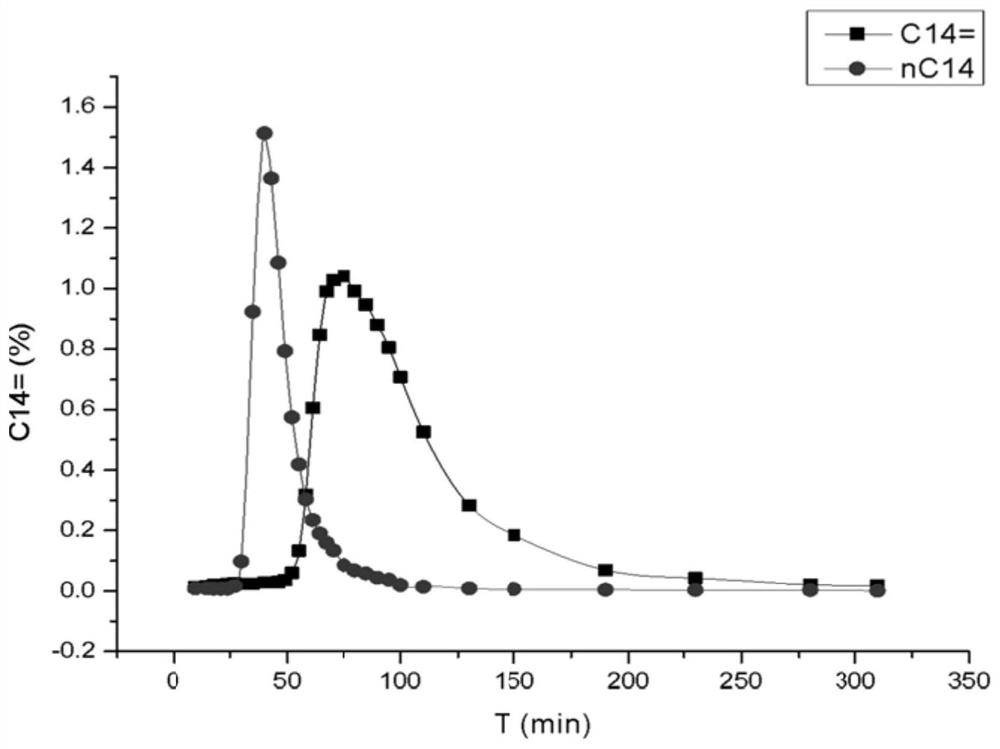

[0046] In this embodiment, the raw material to be separated is C14 component, and the eluent is C10 paraffin.

[0047] C14 raw materials: n-tetradecane 30% (w / w), 1-tetradecene 70% (w / w), before the alkanes are separated, the raw materials are pretreated to remove poisons that may cause adsorption failure ( such as oxygenated organic compounds, benzene, water, etc.).

[0048] C10 eluent: n-decane. Before alkanes are separated, the eluent is pretreated to remove poisons that may cause adsorption failure (such as oxygen-containing organic compounds, benzene, water, etc.).

[0049] Separation of the C14 feed was performed in a simulated moving bed unit using the C10 eluent. Operating conditions of the simulated moving bed: molecular sieve adsorbents and not limited to modified molecular sieve adsorbents are used as the adsorbent; the operating temperature is 250°C; the operating pressure is 2Mpa.

[0050] The distribution of C14 in the simulated moving bed adsorption tube is as...

Embodiment 2

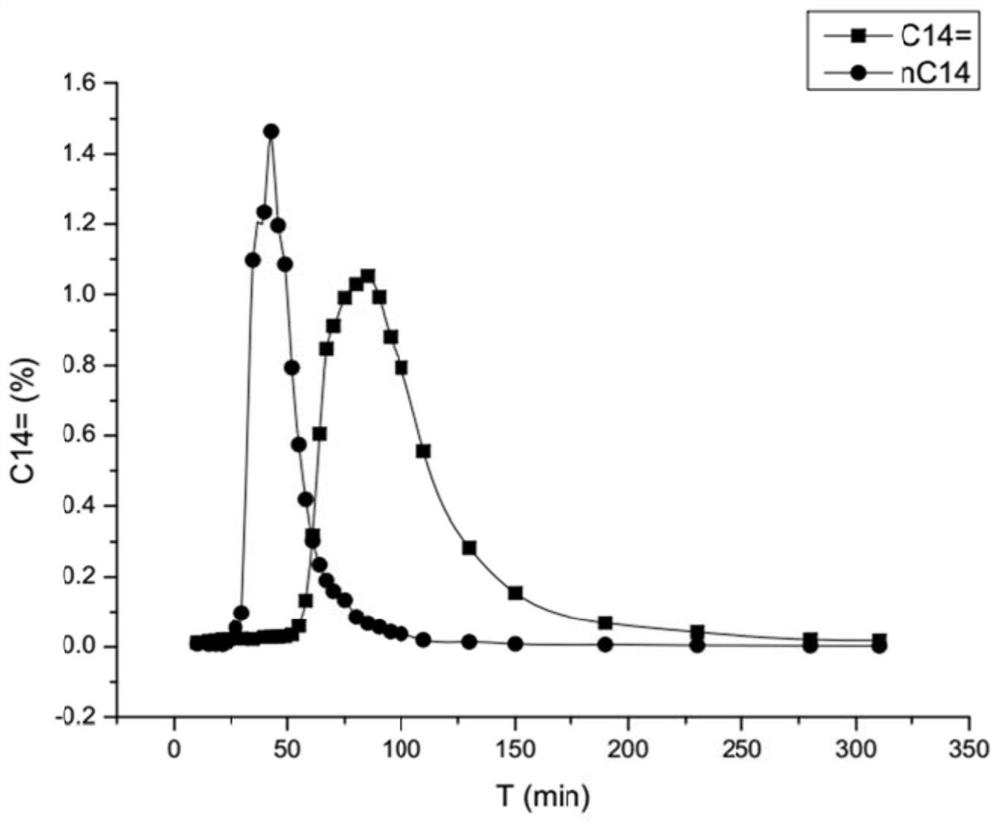

[0055] In this embodiment, the raw material to be separated is C14 component, and the eluent is C16 alkanes.

[0056] C14 raw materials: n-tetradecane 30% (w / w), 1-tetradecene 70% (w / w), before the alkanes are separated, the raw materials are pretreated to remove poisons that may cause adsorption failure ( such as oxygenated organic compounds, benzene, water, etc.).

[0057] C16 eluent: n-hexadecane. Before alkanes are separated, the eluent is pretreated to remove poisons that may cause adsorption failure (such as oxygen-containing organic compounds, benzene, water, etc.).

[0058] Separation of the C14 feed was performed in a simulated moving bed unit using the C16 eluent. Operating conditions of the simulated moving bed: molecular sieve adsorbents and not limited to modified molecular sieve adsorbents are used as the adsorbent; the operating temperature is 100°C; the operating pressure is 1Mpa.

[0059] The distribution of C14 in the simulated moving bed adsorption tube is...

Embodiment 3

[0064] In this embodiment, the raw material to be separated is C10 component, and the eluent is C16 alkanes.

[0065] C10 raw material: n-decane 30% (w / w), 1-decene 70% (w / w), before the alkanes are separated, the raw material is pretreated to remove poisons that may cause adsorption failure (such as containing oxygen organic compounds, benzene, water, etc.).

[0066] C16 eluent: n-hexadecane. Before alkanes are separated, the eluent is pretreated to remove poisons that may cause adsorption failure (such as oxygen-containing organic compounds, benzene, water, etc.).

[0067] Separation of the C10 feed was performed in a simulated moving bed unit using a C16 eluent. Operating conditions of the simulated moving bed: the adsorbent adopts molecular sieve adsorbent and modified molecular sieve adsorbent; the operating temperature is 180°C; the operating pressure is 0.5Mpa.

[0068] The distribution of C10 in the simulated moving bed adsorption tube is as follows: Figure 4 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com