Multi-metal deactivator for catalytic device of refinery plant and preparation method thereof

A catalytic device, multi-metal technology, applied in catalytic cracking, catalyst protection, chemical instruments and methods, etc., can solve the problems of irritating odor, poor high temperature resistance, long reaction time, etc., to improve the passivation effect, The effect of improving process efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

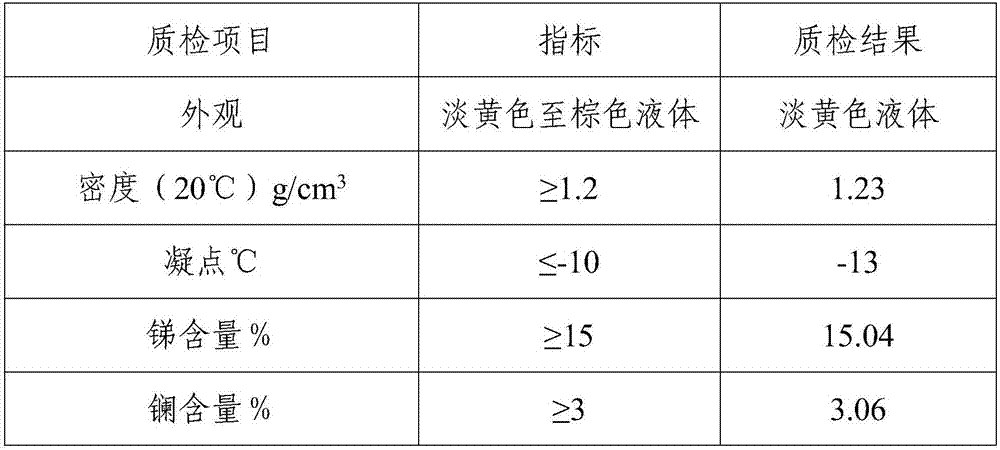

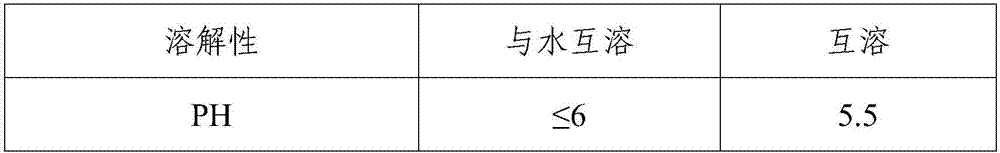

Embodiment 1

[0018] A kind of multi-metal passivation agent for refinery catalytic device, it is compounded by A agent and B agent with a mass ratio of 1:0.25, and the A agent includes antimony trioxide, triethylamine, tartaric acid, hydrogen peroxide and desulfurized Ionized water, agent B includes lanthanum acetate, glacial acetic acid and deionized water.

[0019] Among them, the percentage content of each component in Agent A is as follows: 25% antimony trioxide, 5.5% triethylamine, 3.2% tartaric acid, 35% hydrogen peroxide, and the balance of deionized water; the percentage content of each component in Agent B For example: rare earth acetate 15%, glacial acetic acid 3%, deionized water 82%.

[0020] The preparation method of agent A is as follows: add antimony trioxide, tartaric acid, and triethylamine into deionized water, stir and heat to 50°C, then add hydrogen peroxide dropwise, react at 102°C for 2 hours, after the addition is completed, keep warm at 100°C for 1 hour , get A age...

Embodiment 2

[0024] A multi-metal passivation agent for a refinery catalyst unit, which is compounded by A agent and B agent with a mass ratio of 1:0.22, and the A agent includes antimony trioxide, triethylamine, tartaric acid, hydrogen peroxide, and desulfurized Ionized water, agent B includes cerium acetate, glacial acetic acid and deionized water.

[0025] Among them, the percentage content of each component in Agent A is as follows: 28% antimony trioxide, 5.2% triethylamine, 3% tartaric acid, 40% hydrogen peroxide, and the balance of deionized water; the percentage content of each component in Agent B For example: rare earth acetate 15%, glacial acetic acid 3%, deionized water 82%.

[0026] The preparation method of agent A is as follows: add antimony trioxide, tartaric acid, and triethylamine into deionized water, stir and heat to 50°C, then add hydrogen peroxide dropwise, react at 102°C for 2 hours, after the addition is completed, keep warm at 100°C for 1 hour , get A agent.

[00...

Embodiment 3

[0030] A multi-metal passivation agent for refinery catalytic devices, which is compounded by A agent and B agent with a mass ratio of 1:0.2, and the A agent includes antimony trioxide, triethylamine, tartaric acid, hydrogen peroxide and detoxified Ionized water, agent B includes lanthanum acetate, glacial acetic acid and deionized water.

[0031] Among them, the percentage content of each component in Agent A is as follows: 20% antimony trioxide, 5% triethylamine, 3.6% tartaric acid, 38% hydrogen peroxide, and the balance of deionized water; the percentage content of each component in Agent B For example: rare earth acetate 15%, glacial acetic acid 3%, deionized water 82%.

[0032] The preparation method of agent A is as follows: add antimony trioxide, tartaric acid, and triethylamine into deionized water, stir and heat to 50°C, then add hydrogen peroxide dropwise, react at 102°C for 2 hours, after the addition is completed, keep warm at 100°C for 1 hour , get A agent.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com