Reactivation method of waste catalytic cracking catalyst, and application thereof

A catalytic cracking and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of complex process and high cost, achieve high micro-reaction activity, stable micro-reaction activity, and improve micro-reaction. Reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

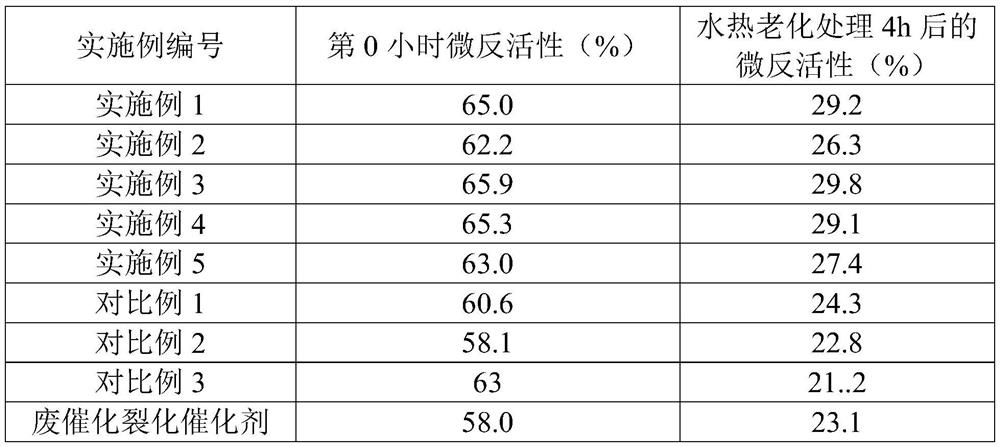

Examples

Embodiment 1-5 and comparative example 1-2

[0033] (1) 60g of spent catalytic cracking catalyst is placed in a microwave muffle furnace, and roasted according to the conditions shown in Table 1;

[0034] (2) Get 50 g of the product of step (1) and water to mix in a beaker according to the conditions shown in Table 1, and perform ultrasonication according to the conditions shown in Table 1.

[0035] (3) The product of step (2) is cooled to room temperature, suction filtered, washed with deionized water, and dried (180° C., 30 hours) in a blast drying oven according to the conditions shown in Table 1 to obtain a revived catalytic cracking catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com