A method for improving the activity of a vanadium-contaminated catalytic cracking catalyst

A catalytic cracking and catalyst technology, used in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of negative impact of catalyst performance, limited improvement of catalyst activity, and difficulty in accurate control of dosage, etc. The reaction conditions are economical and not harsh, the equipment investment is reduced, and the effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

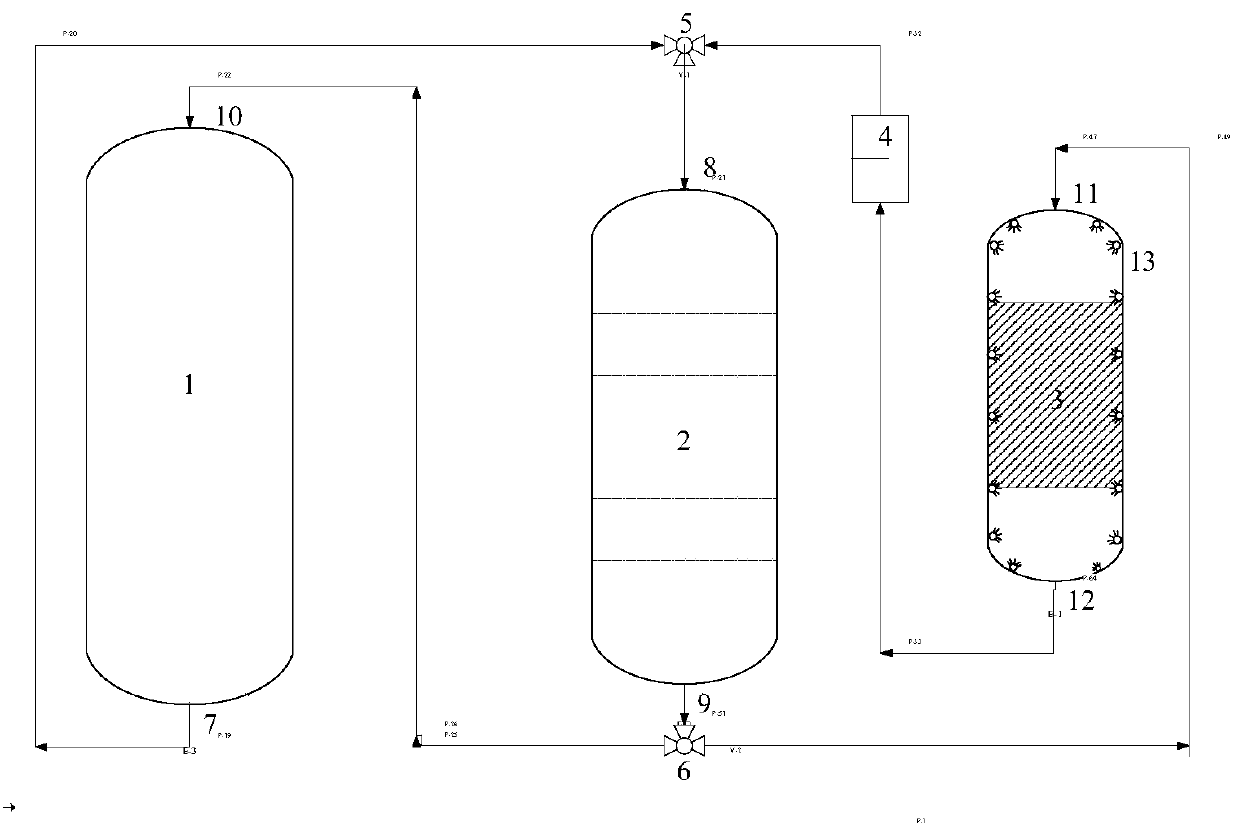

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

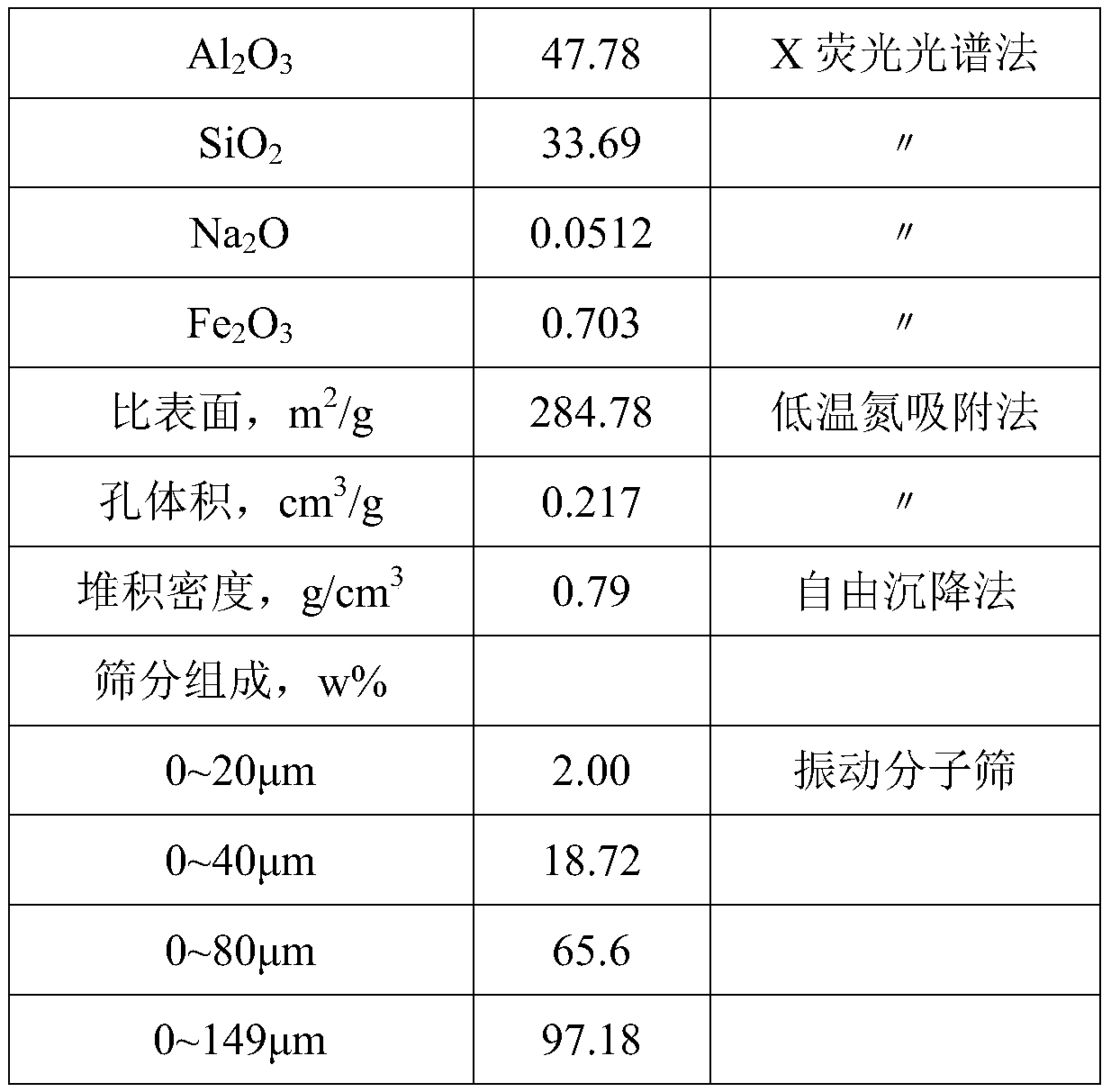

[0038] Determination of Ni, V, Fe and other metal content in the catalyst: use ZSX Primus Ⅱ X-ray fluorescence spectrometer (XRF) to measure, test basis: SN / T 1504.5-2005 standard.

[0039] The V price position measurement of catalyst adopts the chemical adsorption method (TPR) of American AutoChem II2920 multifunctional adsorption instrument to measure the average valence state of V on the catalyst, and the reducing gas composition (volume fraction) is H 2 25%, N 2 75%, the gas flow rate is 50ml / min, and the heating rate is 10°C / min. After the temperature is raised to 450°C for reduction, the sample is oxidized in air at 300°C for 1 hour, and cooled to room temperature for the second temperature-programmed reduction.

[0040] Determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com