High-efficiency composite flux for lowering the melting point of coal ash and its preparation method and application

A technology of flux and melting point, used in the manufacture of combustible gas, gasification process, granular/powder fuel gasification, etc., can solve the problems of high cost and large amount of addition, and achieve low ash content, small amount of addition, and fluxing obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

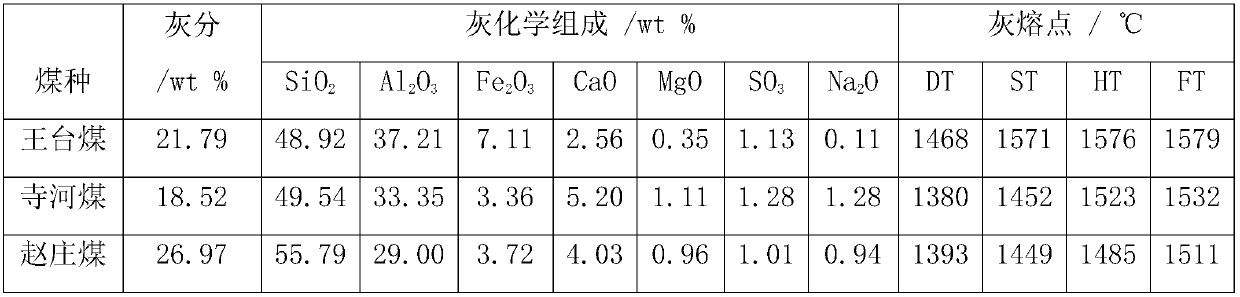

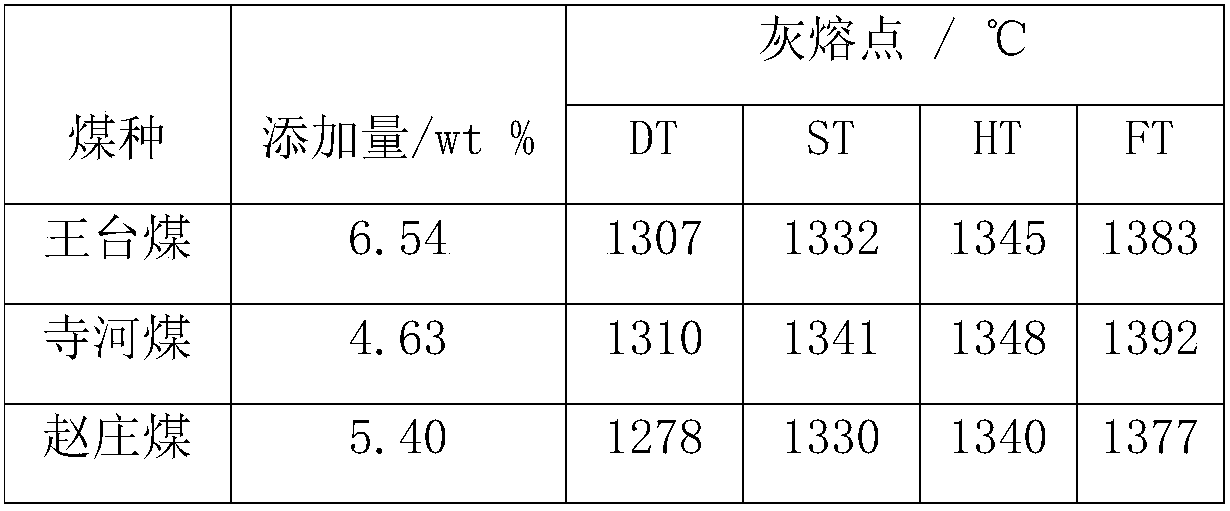

Embodiment 1

[0022] Embodiment 1: Limestone ore powder (containing 98.2wt% CaCO 3 ) and industrial by-product Yuanming powder (mainly containing 98.6wt% Na 2 SO 4 , 1.3wt% CaO) is fully mixed with a ratio of 1:1 to make a composite flux, and then the mass fraction is 1.09%, 0.93% and 1.08% (based on coal, the number of flux parts added in 100 parts of coal ) were added to Wangtai coal, Sihe coal and Zhaozhuang coal respectively, and mixed evenly. The effect of composite flux on the melting point of coal ash is shown in Table 3.

Embodiment 2

[0023] Embodiment 2: Limestone ore powder (mainly containing 97.8wt% CaCO 3 ) and industrial by-product Yuanming powder (mainly containing 98.3wt% Na 2 SO 4, 1.1wt% CaO) is fully mixed with a ratio of 6:4 to make a composite flux, and then the mass fraction is 1.52%, 1.11% and 1.21% (based on coal, the number of flux parts added in 100 parts of coal ) were added to Wangtai coal, Sihe coal and Zhaozhuang coal respectively, and mixed evenly. The effect of composite flux on the melting point of coal ash is shown in Table 4.

Embodiment 3

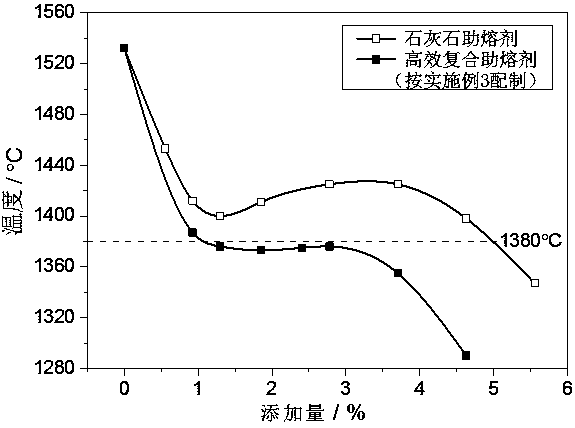

[0024] Embodiment 3: Limestone ore powder (containing 98.3wt% CaCO 3 ) and industrial by-product Yuanming powder (containing 98.3wt%Na 2 SO 4 , 1.1wt% CaO) is fully mixed with a ratio of 7:3 to make a composite flux, and then the mass fraction is 1.74%, 1.30% and 1.35% (based on coal, the number of flux added in 100 parts of coal) The composite flux was added to Wangtai coal, Sihe coal and Zhaozhuang coal respectively, and mixed evenly. The effect of composite flux on the melting point of coal ash is shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com