Fire fighting method

A mixture and quality technology, applied in fire rescue, earthwork drilling, fire prevention, etc., can solve the problems of water gas explosion, unsatisfactory small range, sudden fire, long injection time, etc., to prevent the generation of water gas, Solve the effect of short storage time and ensure fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

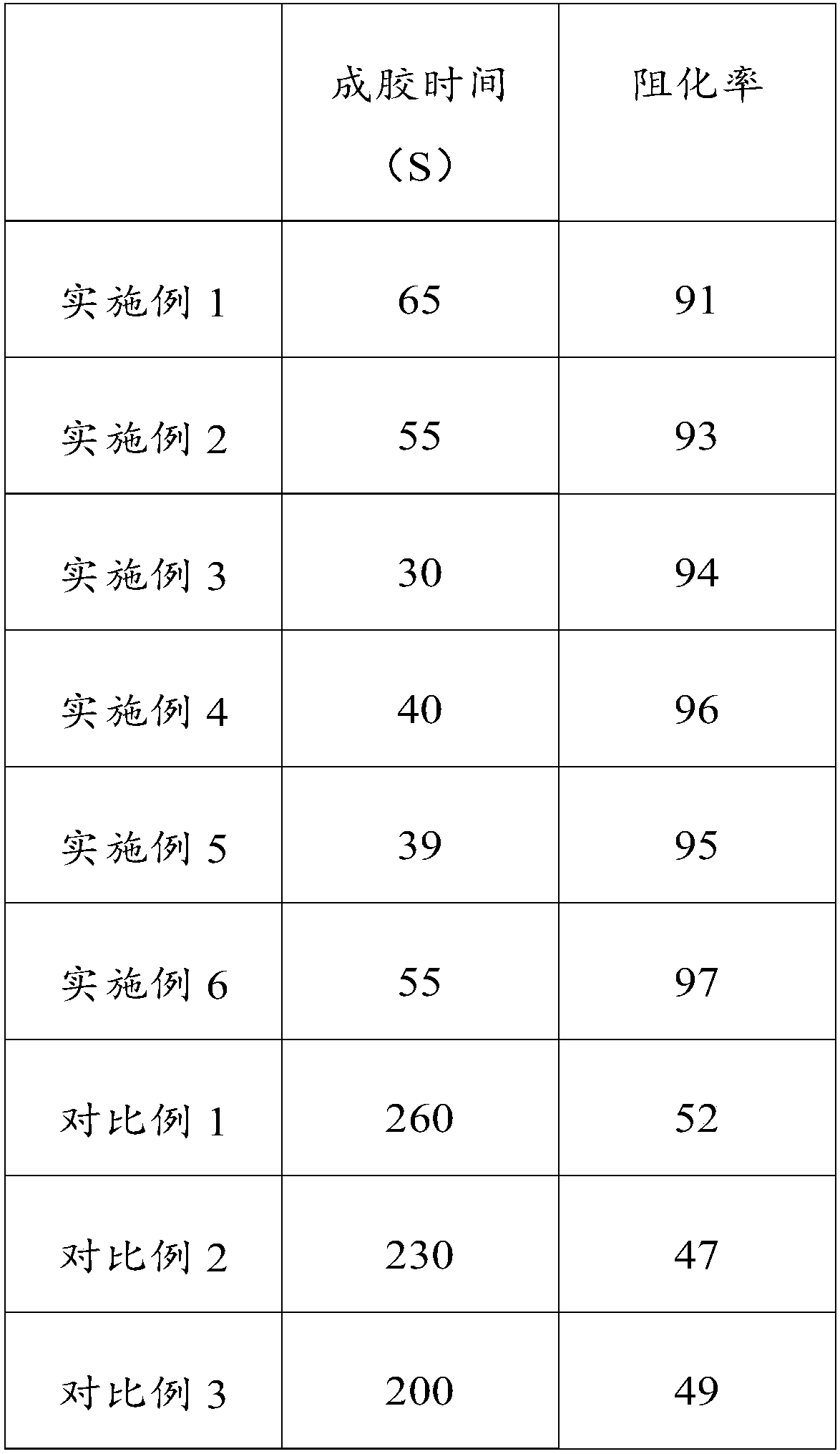

Examples

Embodiment 1

[0026] The present embodiment provides a kind of fire extinguishing method, comprises the following steps:

[0027] Sodium bicarbonate and 5% water were uniformly mixed to obtain a second mixture.

[0028] Mix the water glass with the polyferric sulfate and the remaining water evenly to obtain the first mixture.

[0029] Mix the first mix with 2m 3 / s flow rate and the second mixture at 1.5m 3 / s flow hedging and mixing to obtain the total mixture, and then inject the total mixture to the surface of the coal mine, various gaps and ignition points.

[0030] Wherein, water glass accounts for 13% of total mixture quality, sodium bicarbonate accounts for 3% of total mixture quality, polyferric sulfate accounts for 2% of total mixture quality, and balance is water.

Embodiment 2

[0032] The present embodiment provides a kind of fire extinguishing method, comprises the following steps:

[0033] Sodium bicarbonate and 10% water were uniformly mixed to obtain a second mixture.

[0034] Mix the water glass with the polyferric sulfate and the remaining water evenly to obtain the first mixture.

[0035] Mix the first mix at 2.5m 3 / s flow rate and the second mixture at 2m 3 / s flow hedging and mixing to obtain the total mixture, and then inject the total mixture to the surface of the coal mine, various gaps and ignition points.

[0036] Wherein, water glass accounts for 20% of total mixture quality, sodium bicarbonate accounts for 15% of total mixture quality, polyferric sulfate accounts for 3% of total mixture quality, and balance is water.

Embodiment 3

[0038] The present embodiment provides a kind of fire extinguishing method, comprises the following steps:

[0039] Sodium bicarbonate and 15% water were uniformly mixed to obtain a second mixture.

[0040] Mix the water glass with the polyaluminum chloride and the remaining water evenly to obtain the first mixture.

[0041] Mix the first mix at 3m 3 / s flow rate and the second mixture at 2.5m 3 / s flow hedging and mixing to obtain the total mixture, and then inject the total mixture to the surface of the coal mine, various gaps and ignition points.

[0042] Wherein, water glass accounts for 15% of total mixture quality, sodium bicarbonate accounts for 4% of total mixture quality, polyaluminum chloride accounts for 2.5% of total mixture quality, and balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com