Method for silt soil with ectopic activated magnesium oxide carbonization and solidification

A technology of activated magnesia and solidified sludge, which is applied in soil protection, dehydration/drying/concentrated sludge treatment, construction, etc. It can solve the difficulties in the application of low-permeability sludge engineering, unsuitable for high moisture content sludge, waste of carbon dioxide, etc. problems, to achieve the effect of increasing the scope of application, high integrity, and avoiding escape and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

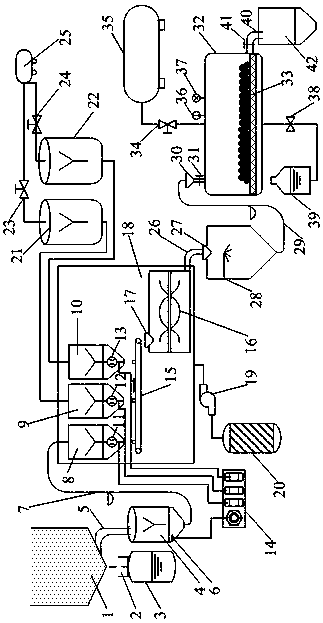

[0033] A method for carbonizing and solidifying silt soil with ex-situ active magnesium oxide comprises the following steps:

[0034] a. Sludge pretreatment: The sludge to be treated is transported to the pretreatment device 1 by a transport vehicle or a mud pump, and the procedures of debris removal, sediment separation and dehydration and volume reduction are carried out in sequence, and the debris removal is mainly for solid debris , such as grass roots and debris bags in the soil, then turn on the sediment separation function, separate the sediment through a mechanical sieve, and finally perform dehydration and volume reduction to separate the pretreated water and soil and store them in the water storage tank 3 and cache bin 4;

[0035] b. Uniform mixing of curing agent: the soil in the buffer storehouse 4 is transported to the metering hopper A8 through the feeder A7, and the first pressure regulating valve 23 and the second pressure regulating valve 24 are opened at the ...

Embodiment 2

[0042] On the basis of Example 1, the soil pretreated in step a obtains the moisture monitoring value through the moisture sensor 6, and the soil, the first curing agent and the second curing agent in step b are respectively equipped with metering sensor A11 and metering sensor B12 and metering sensor C13, first determine the metering sensor A11 to any reference value, then adjust the metering sensor B12 according to the moisture monitoring value, and adjust the metering sensor C13 according to the target strength and hardness of the sludge particles;

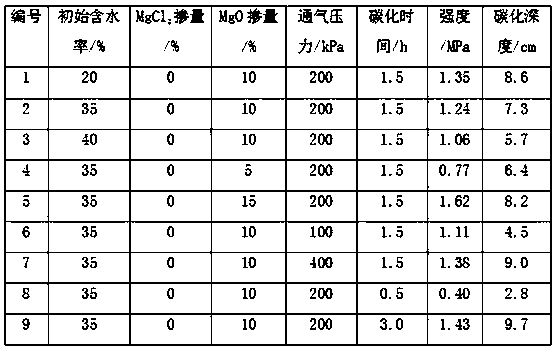

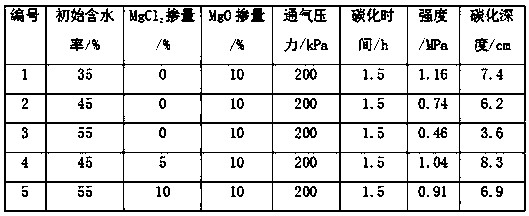

[0043] Specifically, the carbonation degree and strength of silt soil are significantly affected by factors such as silt moisture content, clay (fine particle) content, curing agent content, aeration pressure, and carbonization time. Taking the silt soil in Nanjing, Huai'an and Wenzhou as examples, the characteristics of the silt soil in the three places are different, and then the indoor unit experiment of magnesia solidified s...

Embodiment 3

[0055] On the basis of the above embodiments, the solid debris in step a is removed by mechanical rakes or mechanical sieves, and the separation of sediment is mainly through mechanical centrifugation or geotechnical mesh bag barrier, the overall operation is simple and the efficiency is higher;

[0056] The first curing agent can be anhydrous magnesium chloride powder or a powder mixture of anhydrous magnesium chloride and anhydrous calcium chloride, and the second curing agent is active magnesium oxide powder or a powder mixture of active magnesium oxide and calcium oxide. Magnesium is the main curing agent, and the carbonization and reinforcement process can fully absorb a large amount of carbon dioxide gas and avoid environmental pollution as much as possible.

[0057] The lye in step e can be sodium hydroxide solution, which is easy to obtain and has low economic cost, and is convenient and safe to use. The overall method does not require long-term maintenance and can be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com