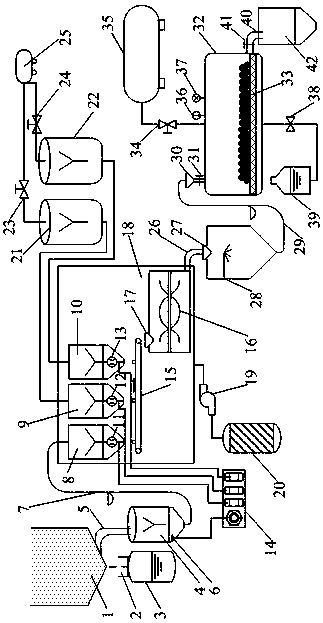

An ex-situ active magnesium oxide carbonization and solidification sludge treatment system

A technology of activated magnesium oxide and solidified sludge, which is used in fixed/solidified sludge treatment, sludge treatment, water/sludge/sewage treatment, etc. , not suitable for high moisture content and other problems, to achieve the effect of high efficiency, environmental protection and sustainability, reducing economic costs and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

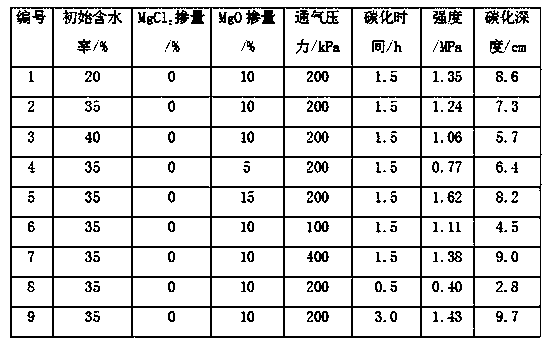

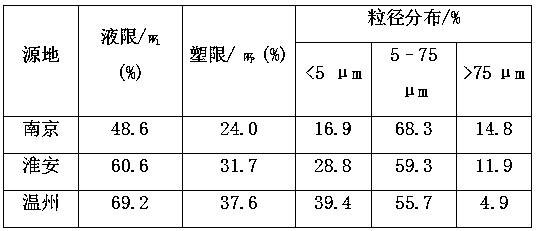

experiment example 1

[0053] If the clay content of the pretreated silt soil is less than 20%, the moisture content is 30%-40%, and the target strength is 0.6MPa, the first curing agent is not selected during the curing agent homogenization process, and the second curing agent content is adjusted to 10%. The granulation process adjusts the maximum particle size to 7cm, the carbonization process controls the ventilation pressure to 200kPa, and the carbonization time to 1.5h.

experiment example 2

[0055] If the clay content of the pretreated silt soil is 20%-30%, the moisture content is less than 45%, and the target strength is 0.6MPa, the curing agent uniform mixing process adjusts the first curing agent to 5%, and adjusts the second curing agent The content is 10%, the maximum particle size is adjusted to 6cm during the granulation process, the aeration pressure is controlled to 200kPa during the carbonization process, and the carbonization time is 1.5h.

experiment example 3

[0057] If the clay content of the pretreated silt soil is less than 20%, the moisture content is 30%-40%, and the target strength is 0.8MPa, the first curing agent is not selected in the curing agent homogenization process, and the second curing agent content is adjusted to 15%. The granulation process adjusts the maximum particle size to 6cm, the carbonization process controls the ventilation pressure to 200kPa, and the carbonization time to 3.0h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com