Method for adding residual sludge anaerobic fermentation liquor of reinforced municipal sewage SBR

A technology for anaerobic fermentation liquid and excess sludge, applied in chemical instruments and methods, biological treatment adjustment methods, special compound water treatment, etc., can solve problems such as inability to dynamically adjust, waste, and insufficient carbon sources, and reduce exposure Effect of Gas Energy Consumption and Fermentation Broth Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

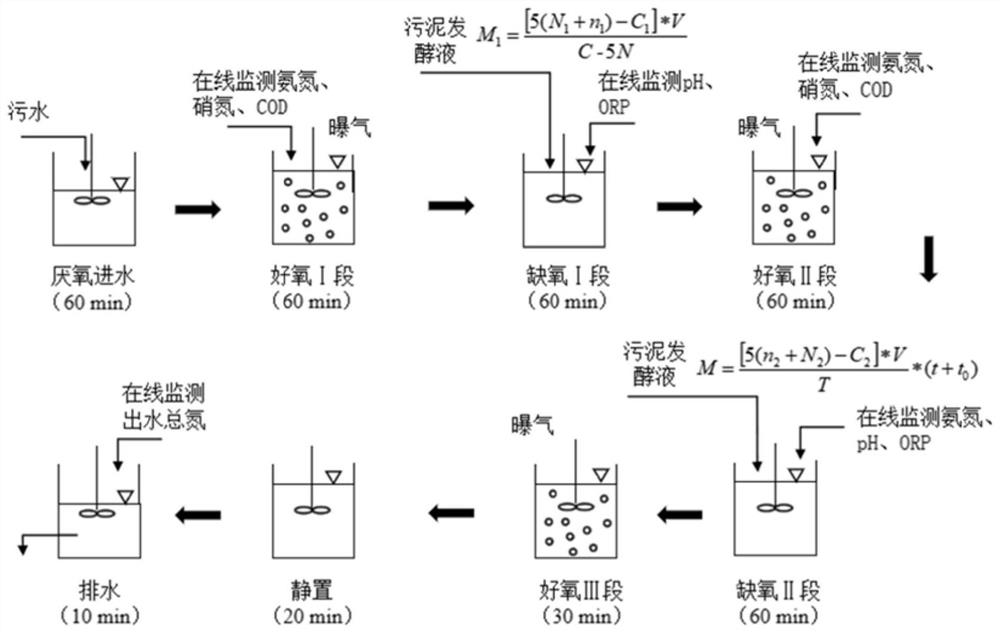

[0046] The invention provides a method for adding sludge fermentation liquid to strengthen the denitrification and phosphorus removal of municipal sewage SBR reactor. Under the method for adding sludge fermentation liquid of the present invention, each operation cycle of the SBR reactor includes Oxygen feed water stirring, aeration stirring (aerobic stage I), anoxic sludge fermentation liquid stirring (anoxic stage I), aeration stirring (aerobic stage II), anoxic sludge fermentation liquid stirring (anoxic Oxygen II stage), aeration stirring (aerobic stage III), and static and drainage operations. The method can cooperate with the SBR reactor commonly used on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com