Production method of epoxy resin board for photo-elastic experimental test

A technology of epoxy resin board and production method, which is applied in the direction of force measurement, measurement force, and measurement device by measuring the change of optical properties of materials when they are stressed, can solve the problems affecting test accuracy, processing difficulties, limitations, etc., Achieve the effect of good transparency, wide application range and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

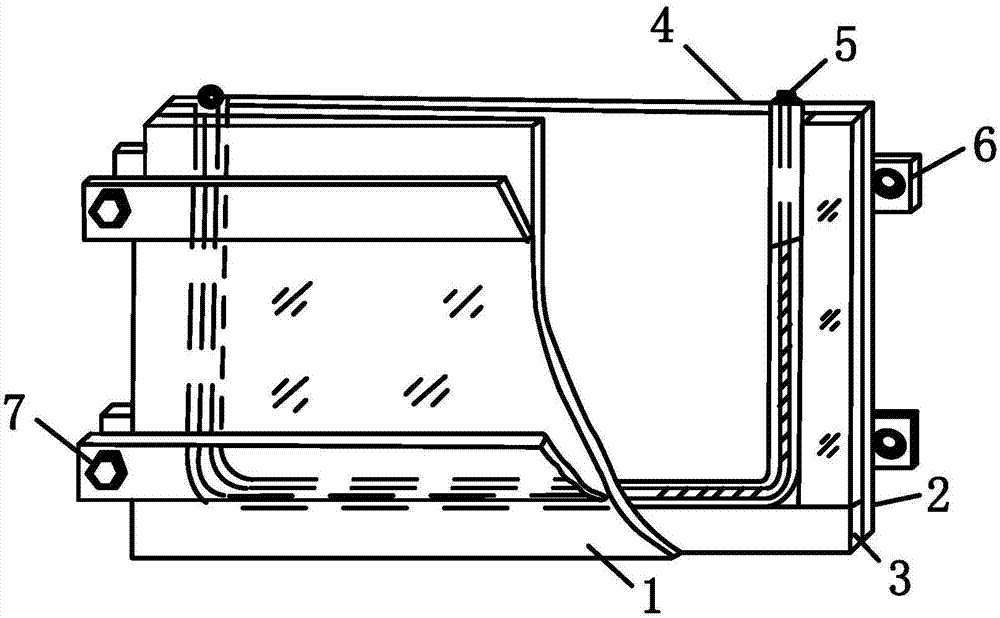

[0037] The used glass mold of the present invention sees figure 1 , including two glass plates 1, 2 and a rubber tube 4 pressed between the two glass plates, the rubber tube 4 is U-shaped, and the upper end surface of the U-shaped rubber tube is surrounded by the inner surfaces of the two glass plates. Into the molding space of the epoxy resin board.

[0038] The pretreatment of the glass mold comprises the following steps:

[0039] (a) Cleaning of glass plates and rubber tubes: first scrub with detergent, then rinse with water, and finally wipe with absolute ethanol and acetone in turn. The glass surface is required to be free of dust, grease, clean and transparent, and air-dry naturally;

[0040] (b) Release agent configuration: mix toluene and polystyrene according to the weight ratio of 10:1, fully dissolve, and the dissolution time is 4-5h;

[0041] (c) Film formation on the surface of the glass plate and rubber tube: Soak the glass plate, glass spacer and rubber tube i...

Embodiment 2

[0044] A kind of production method of the epoxy resin plate that is used for photoelastic experiment test, comprises the following steps:

[0045] (1) Heat 517.58g of 6101 epoxy resin to 120°C, keep it warm for 2 hours while stirring, cool down to 60°C naturally after the heat preservation is over, keep it warm, and set aside;

[0046] (2) Put 103.52g of maleic anhydride in a 70°C oil bath until the maleic anhydride melts, set aside;

[0047] (3) 77.64g dibutyl phthalate, 155.27g 304 polyester resin and the maleic anhydride of step (2) are added in the 6101 epoxy resin of step (1), obtain mixed solution;

[0048] (4) Stir the mixed solution of step (3) with an electric stirrer for 30 minutes under the condition of 60° C. oil bath, and then let stand for 2 hours;

[0049] (5) Preheat the glass mold (Example 1) for preparing the epoxy resin plate at 60°C for 40 minutes, then pour the mixed solution of step (4) into the preheated glass mold, and solidify at 42°C 5d, making a mo...

Embodiment 3

[0059] A kind of production method of the epoxy resin plate that is used for photoelastic experiment test, comprises the following steps:

[0060] (1) Heat 449.47g of 6101 epoxy resin to 120°C, keep it warm for 2 hours while stirring, cool down to 60°C naturally after the heat preservation is over, keep it warm, and set aside;

[0061] (2) Put 67.42g of maleic anhydride in a 70°C oil bath until the maleic anhydride melts, set aside;

[0062] (3) 67.42g dibutyl phthalate, 269.68g 304 polyester resin and the maleic anhydride of step (2) are added in the 6101 epoxy resin of step (1), obtain mixed solution;

[0063] (4) Stir the mixed solution of step (3) with an electronic stirrer for 30 minutes under the condition of 60° C. oil bath, and then let stand for 3 hours;

[0064] (5) Preheat the glass mold (Example 1) for preparing the epoxy resin plate at 60°C for 40 minutes, then pour the mixed solution of step (4) into the preheated glass mold, and solidify at 43°C 5d, making a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com