Machine head of rubber supply extruder of three-roller calender

A three-roll calendering and extruder technology, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of insufficient film compactness and air bubbles, and achieve the effect of film compaction, elimination of film air bubbles, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

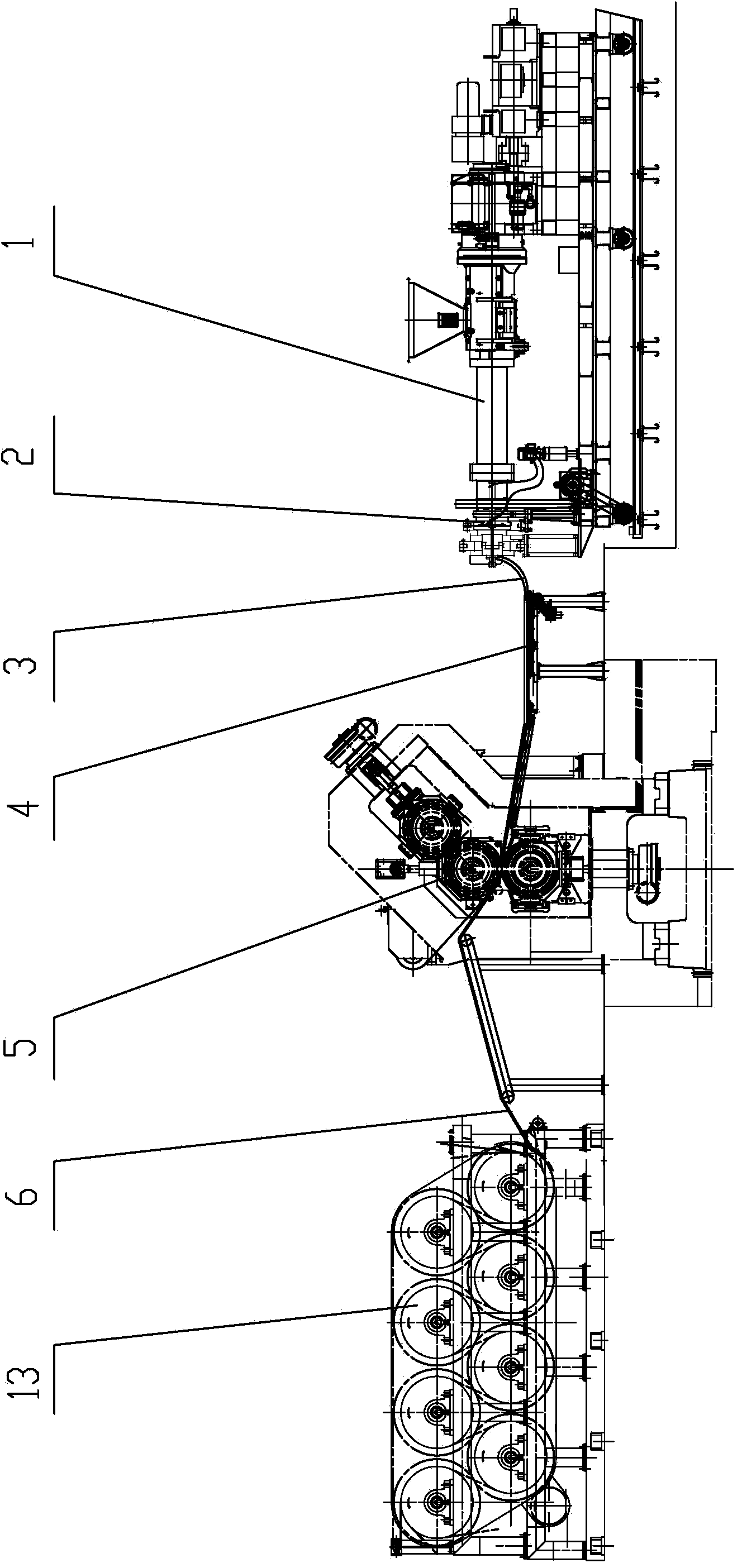

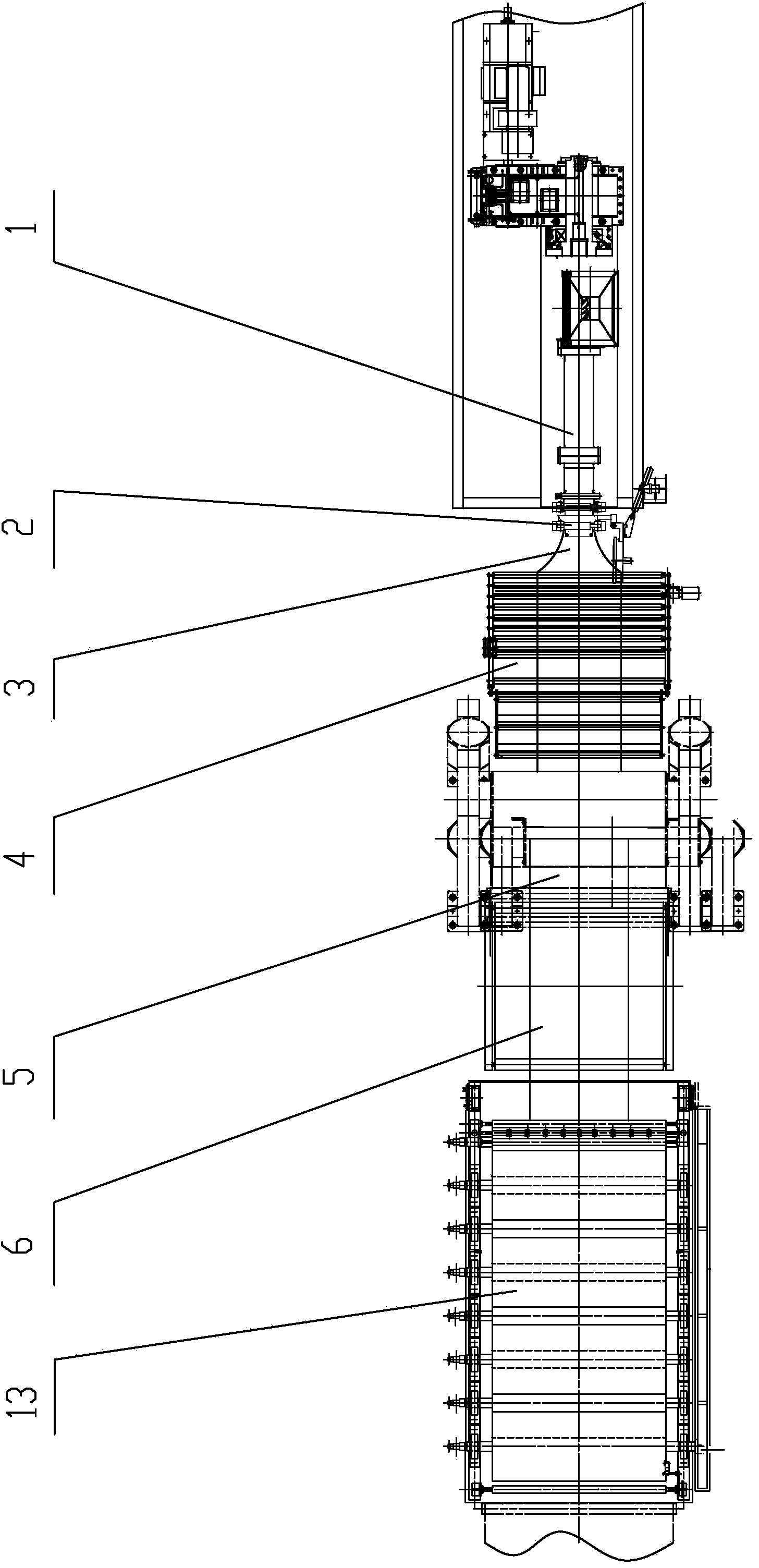

[0028] The wide-width cooling film extrusion and calendering production line includes a pin cold-feed extruder 1, a three-roll calender 5 and a stocker 13 arranged in sequence, and the pin cold-feed extruder 1 and the three-roll calender 5 are arranged in sequence. Connected by feed rack 4, such as figure 1 , figure 2 shown.

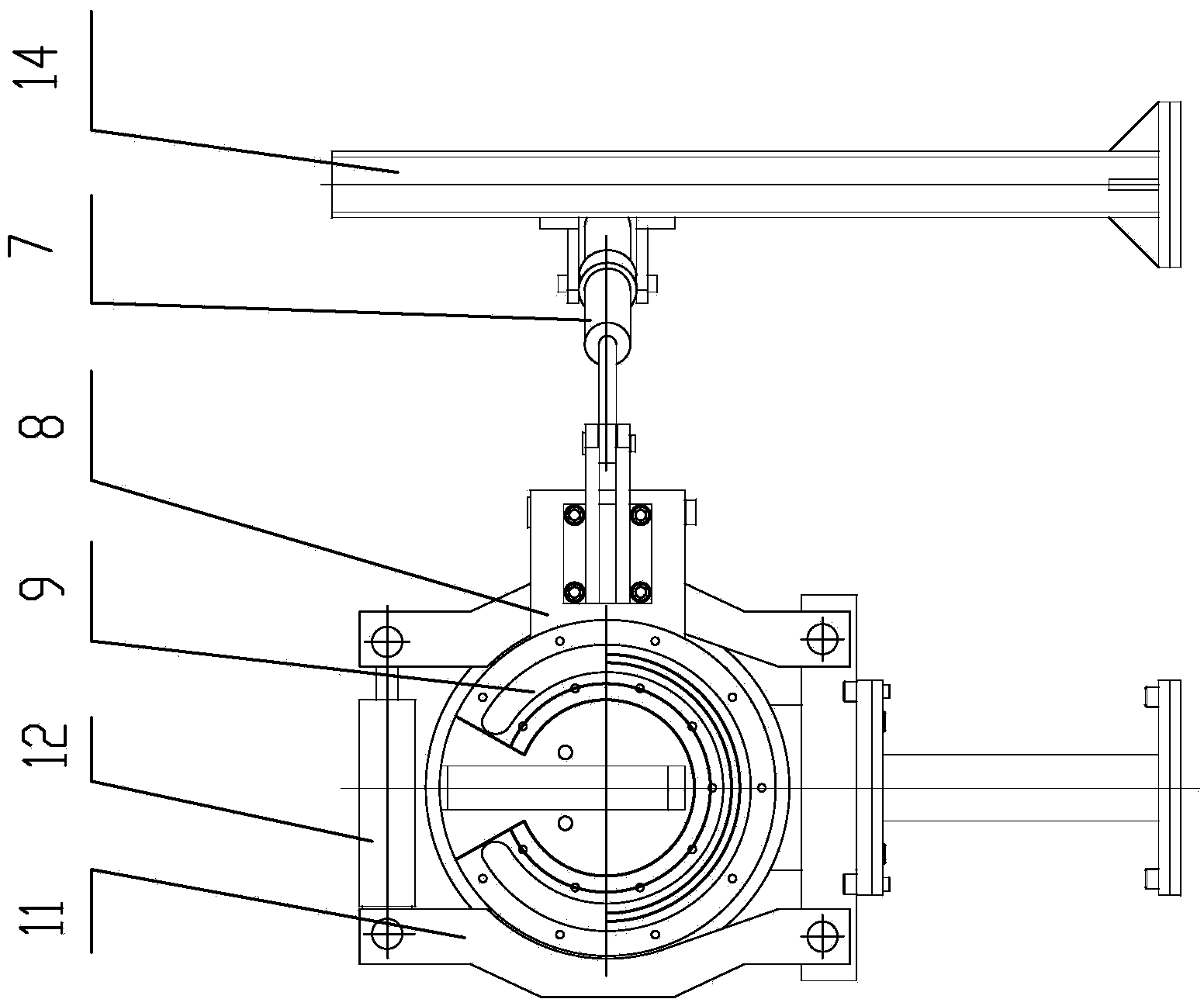

[0029] The mold body 2 of the head of the three-roller calender of the present invention includes a movable head die 8 and a fixed die 10 that are hinged to each other, and the fixed die 10 is fixed on the pin cold feed extrusion The barrel mouth of the nose of the machine 1, the movable mold 8 of the nose is hinged with the fixed mold 10 of the nose and connected with the mold opening and closing device, and the mold opening and closing device is a hydraulic opening and closing mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com