General purpose type wire stranding machine

A strand twisting machine and host technology, applied in the strand twisting machine field, can solve problems such as inability to change flexibly, uneven twisting of steel cords, and affecting the quality of steel cords, etc., to achieve convenient threading, energy saving, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

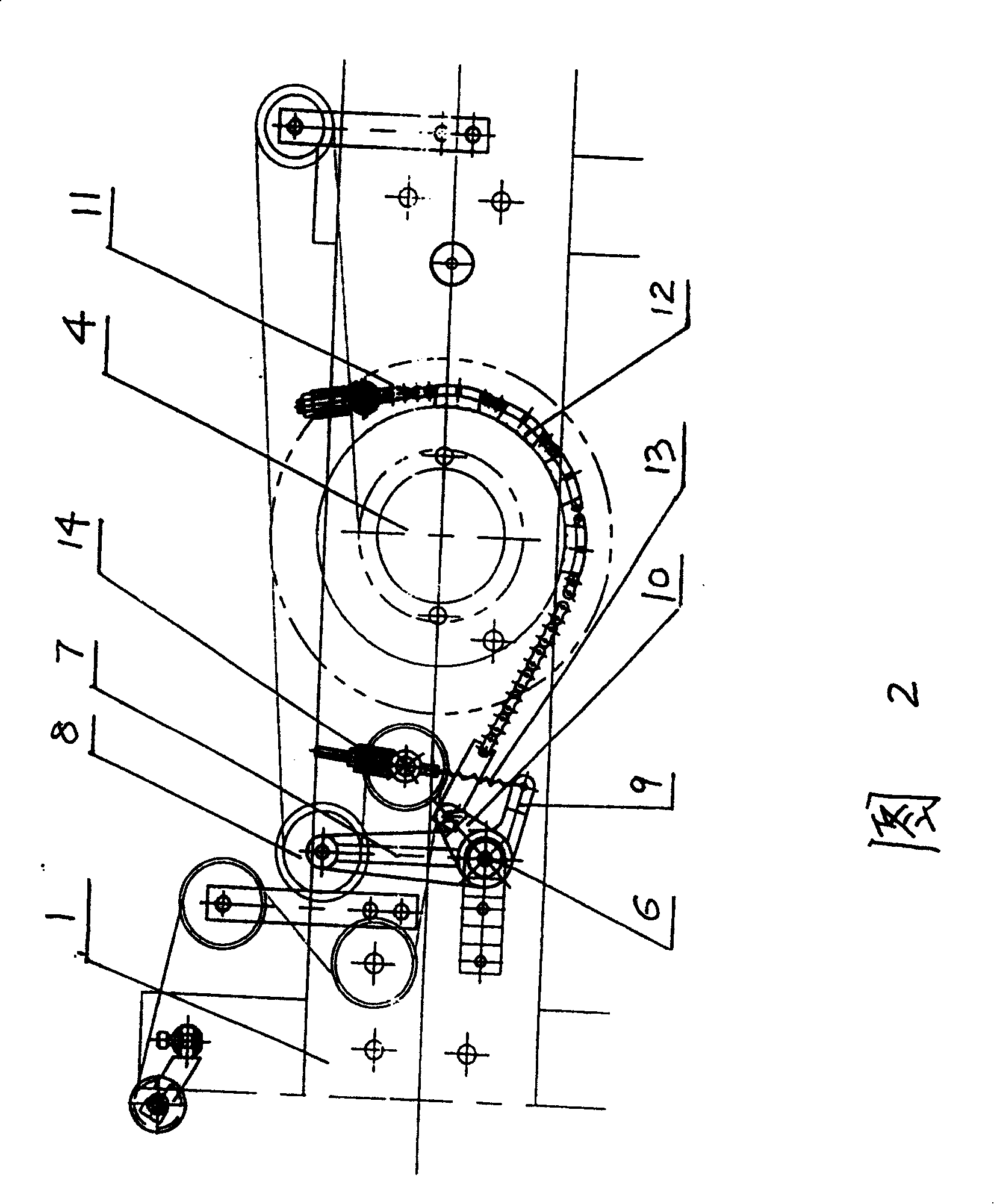

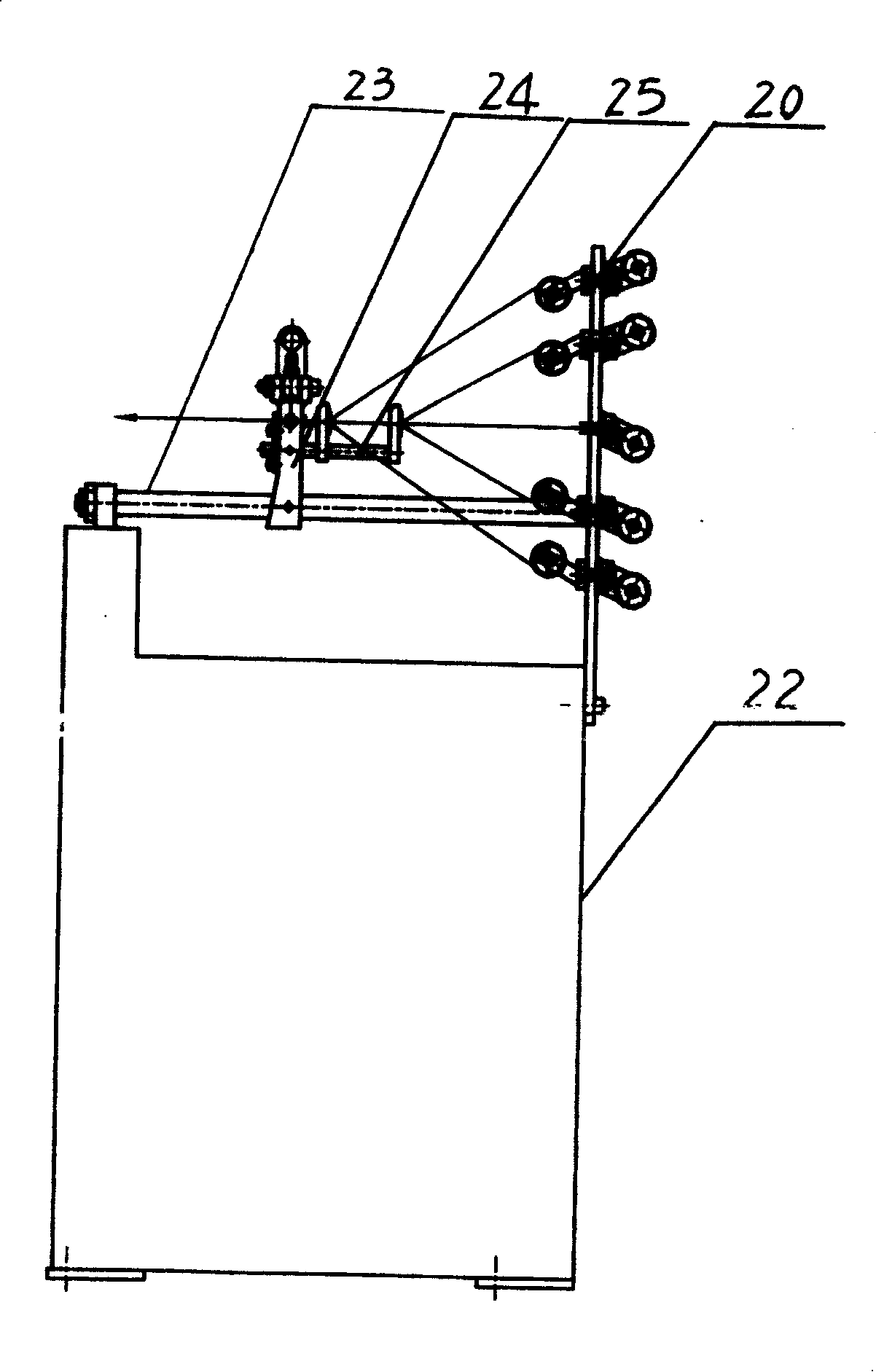

[0022] The present invention is a strand twisting machine, which is mainly composed of a wire-releasing part, a split-line mold-closing part, and a host strand-twisting take-up part. Over-twisting parts can be optionally provided between the twisting and receiving parts of the main machine, which vary according to the structure of the twisted steel cord.

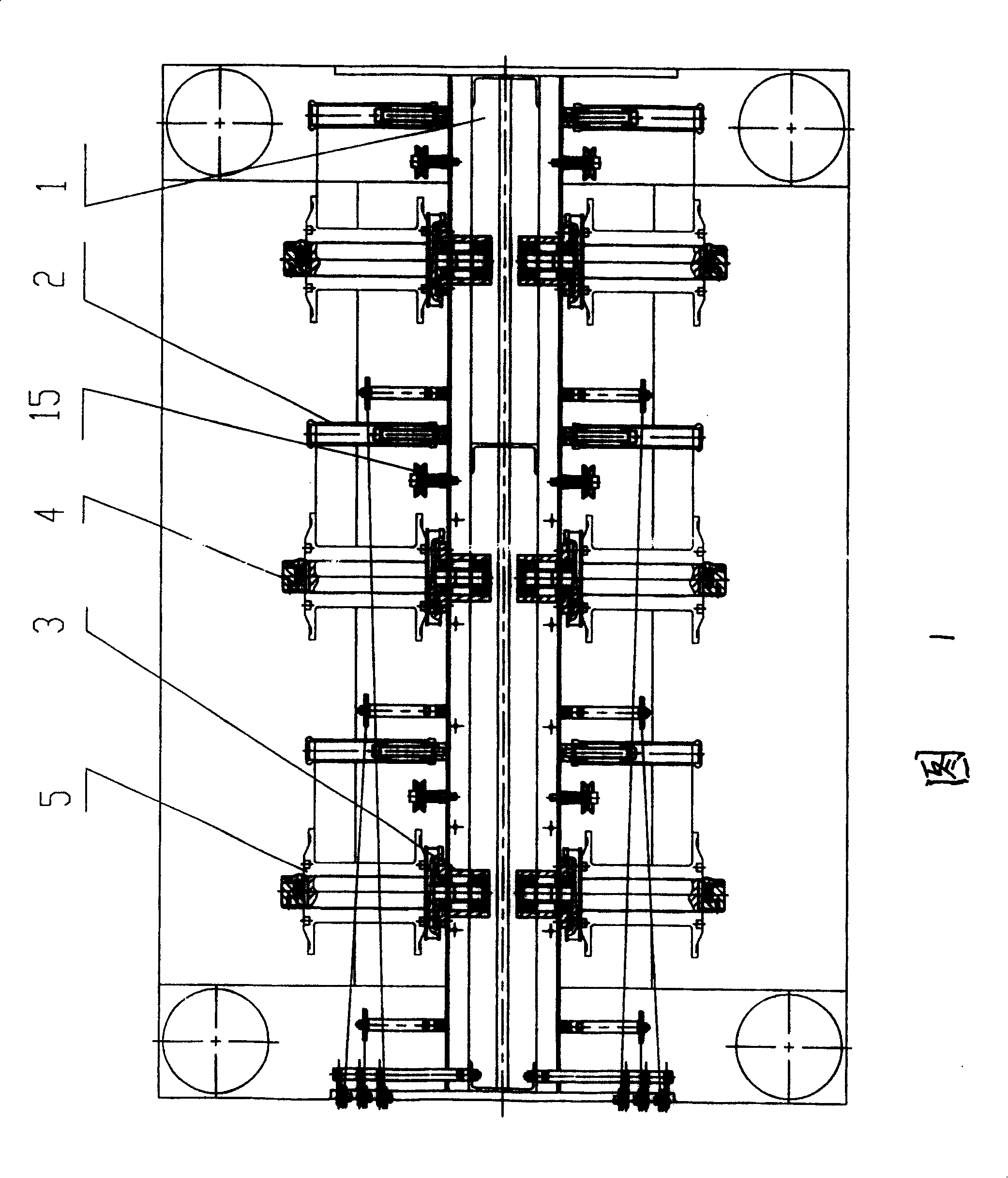

[0023] As shown in Figure 1, the pay-off part includes a pay-off rack 1 and a pay-off seat, the pay-off rack 1 is installed vertically on the ground or on the base, each pay-off seat is composed of a chassis 3 and a main shaft 4, and the chassis 3 is fixed to pay off the wire On the frame 1, the bearings between the chassis 3 and the main shaft 4 are connected, and the main shaft 4 is perpendicular to the pay-off frame 1, that is, each main shaft 4 is horizontally arranged in parallel, and the I-shaped wheel 5 is just placed on the main shaft 4. Conduit 2 and a plurality of guide wheels 15 are arranged around each pay-off se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com