Liftable steel belt reel loading mechanism

A steel strip and reel technology is applied in the field of the loading mechanism of the preloaded high-pressure mold to be wound on the steel reel, which can solve the problems of uneven preloading force and achieve the effect of uniform and accurate prestressing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: overall structure of the present invention and the effect of each part

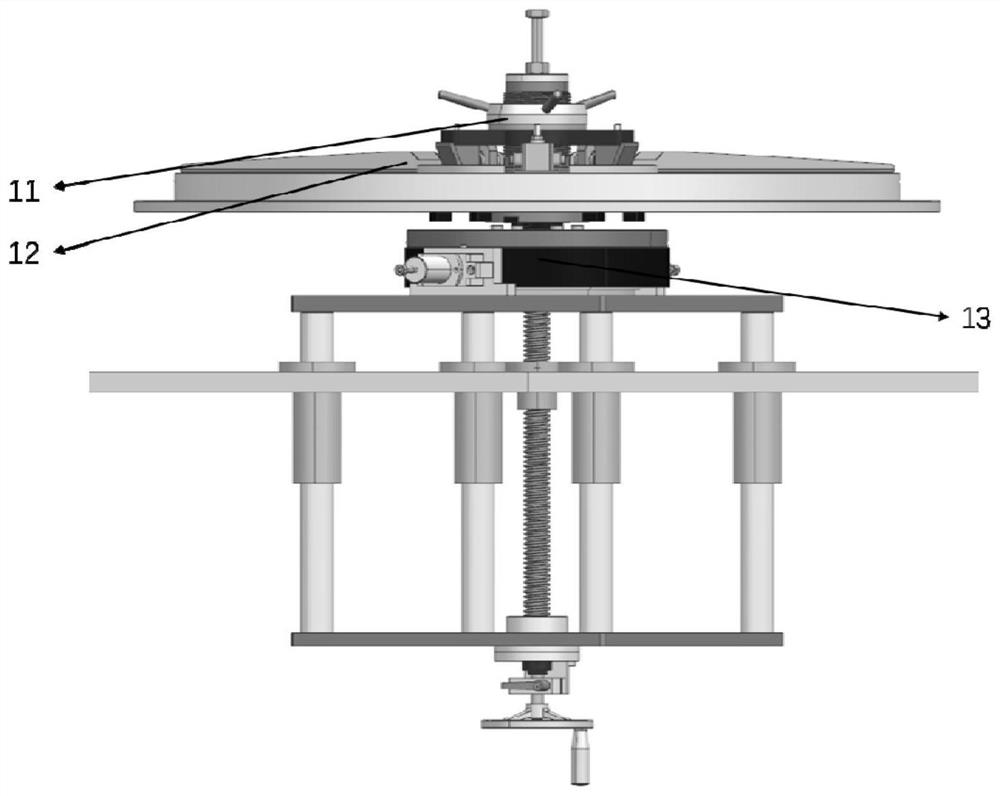

[0026] Such as figure 1 As shown, a liftable steel strip reel loading mechanism of the present invention includes a steel strip tensioning assembly 11, a steel strip upper limit assembly 12 and a steel strip reel lifting assembly 13; the steel strip to be wound is placed on the steel strip carrying turntable 1204, the steel strip reel 1106 is tightened from the inner ring of the steel strip outward by the steel strip tensioning assembly 11, and then the steel strip upper limit assembly 12 is used to limit the axial position of the steel strip reel 1106 to ensure that the steel strip reel 1106 is axially limited during the continuous winding process. The strip output is stable, and the steel strip reel 1106 , the steel strip carrying turntable 1204 , the steel strip tensioning assembly 11 and the steel strip upper limit assembly 12 realize the steel strip height adjustment function thr...

Embodiment 2

[0027] Embodiment 2: the specific structure of steel strip tensioning assembly 11

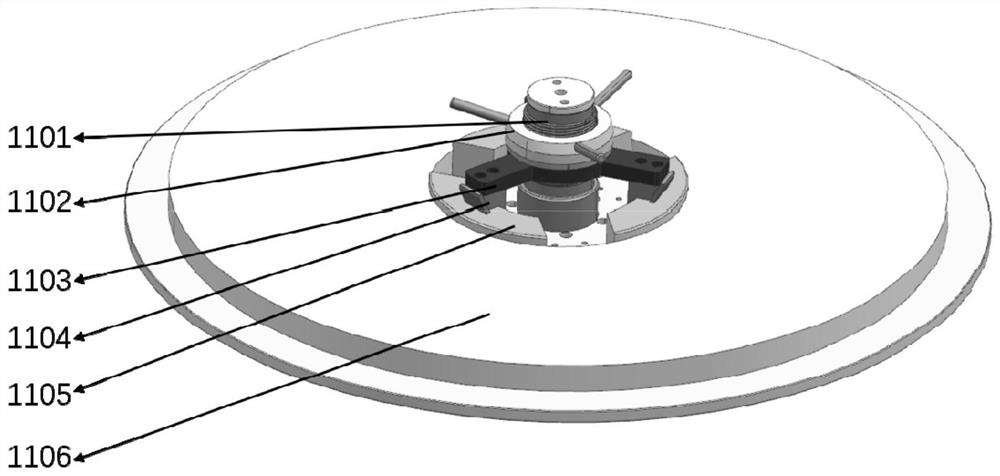

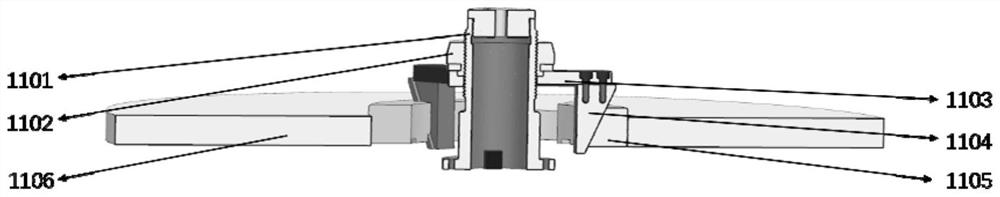

[0028] Such as figure 2 , image 3 As shown, the steel strip reel 1106 to be wound is placed on the steel strip carrying turntable 1204, and the steel strip tensioning push block 1105 passes through the inner diameter of the steel strip reel 1106, and rotates clockwise to lock with the mandrel sleeve 1101. The nut 1102 pushes the inclined pin frame 1103 to move downward, and then the inclined pin 1104 pushes the tensioning push block 1105 to complete the tensioning action of the steel strip reel.

Embodiment 3

[0029] Embodiment 3: the specific structure of the steel band upper limit assembly 12

[0030] Such as Figure 4 , Figure 5 As shown, the tail of the steel strip upper limit plate 1201 in the steel strip upper limit assembly 12 is connected with the rotating shaft seat 1203 through pins, and can realize the action of folding up 90°. The above parts can make the steel strip tighten when the station is folded upward. The components pass through the inner hole of the steel strip reel smoothly, and when the station is folded down, the steel strip reel 1106 can be pressed against the steel strip carrying turntable 1204 through the compression cap 1202, thereby realizing the axial compression limit of the steel strip reel. bit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com