A recycling mechanism for discarded side yarn of air-jet loom

A technology of recovery mechanism and discarded side yarn, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of affecting the quality of fabrics and inaccurate cutting sizes, and achieve the goals of ensuring accuracy, easy cutting, and preventing deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

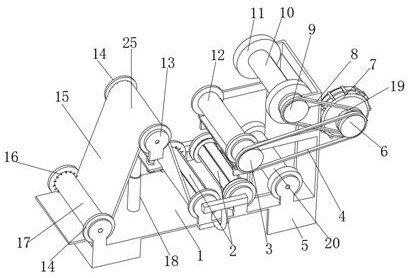

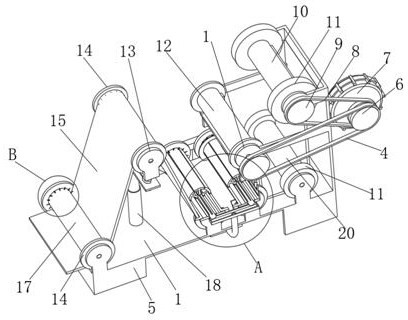

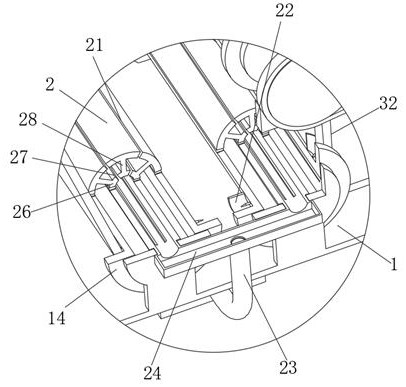

[0029] Such as Figure 1-Figure 7 The shown side yarn recovery mechanism of an air-jet loom includes a base frame 1, and the upper part of the base frame 1 is rotatably installed with a first guide roller 17 and a second guide roller 20 parallel to each other, and the first guide roller 17 and the second guide roller Two guide rollers 2 are installed on the base frame 1 between the two guide rollers 20. The guide rollers 2 are parallel to the first guide roller 17. The first guide roller 17 and the second guide roller 20 are of the same height as the two guide rollers 2. , between the guide roller 2 near the first guide roller 17 and the first guide roller 17, a mounting frame 13 is provided, the mounting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com