Large-sheet single-table inkjet machine

A single-table, ink-jet technology, applied to typewriters, transfer materials, power transmission devices, etc., can solve problems such as board warping and cannot be produced normally, and achieve the effects of solving abnormal production, fast alignment, and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

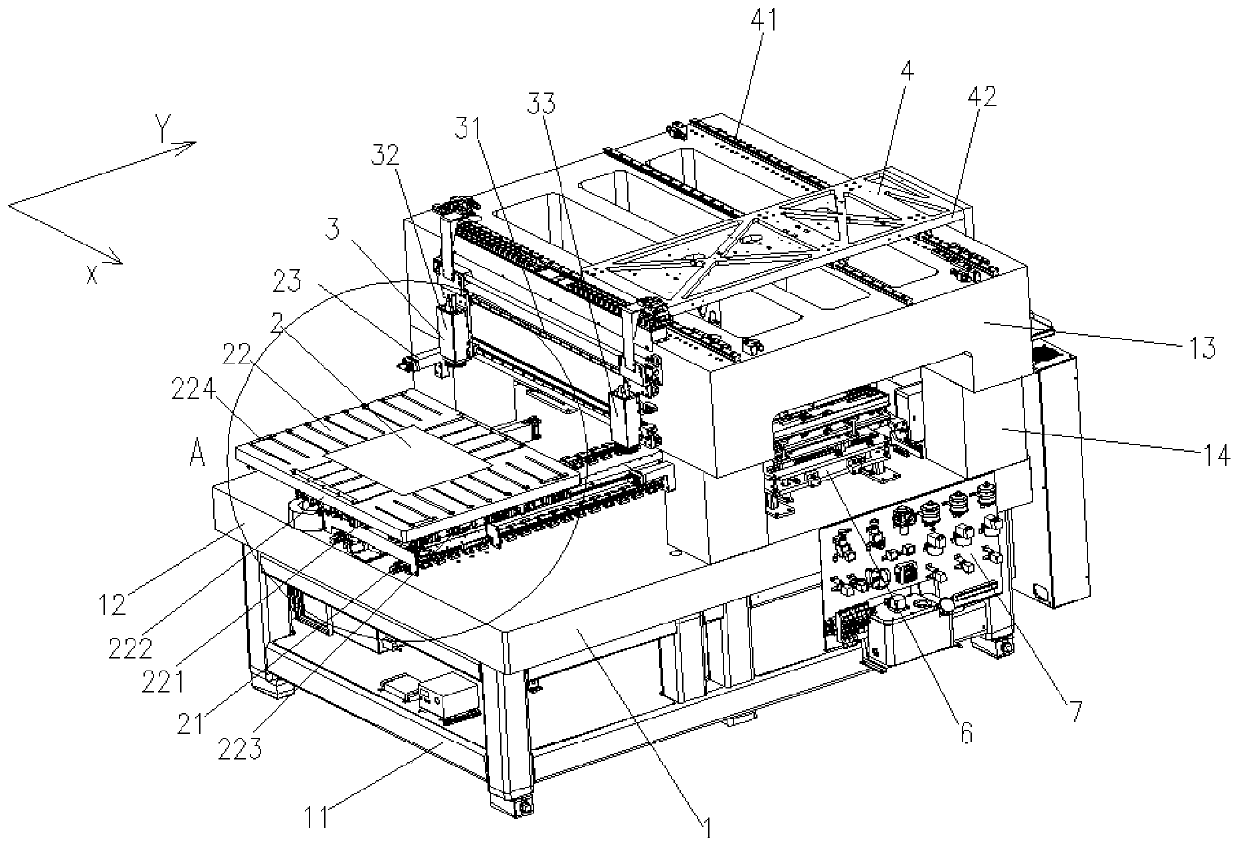

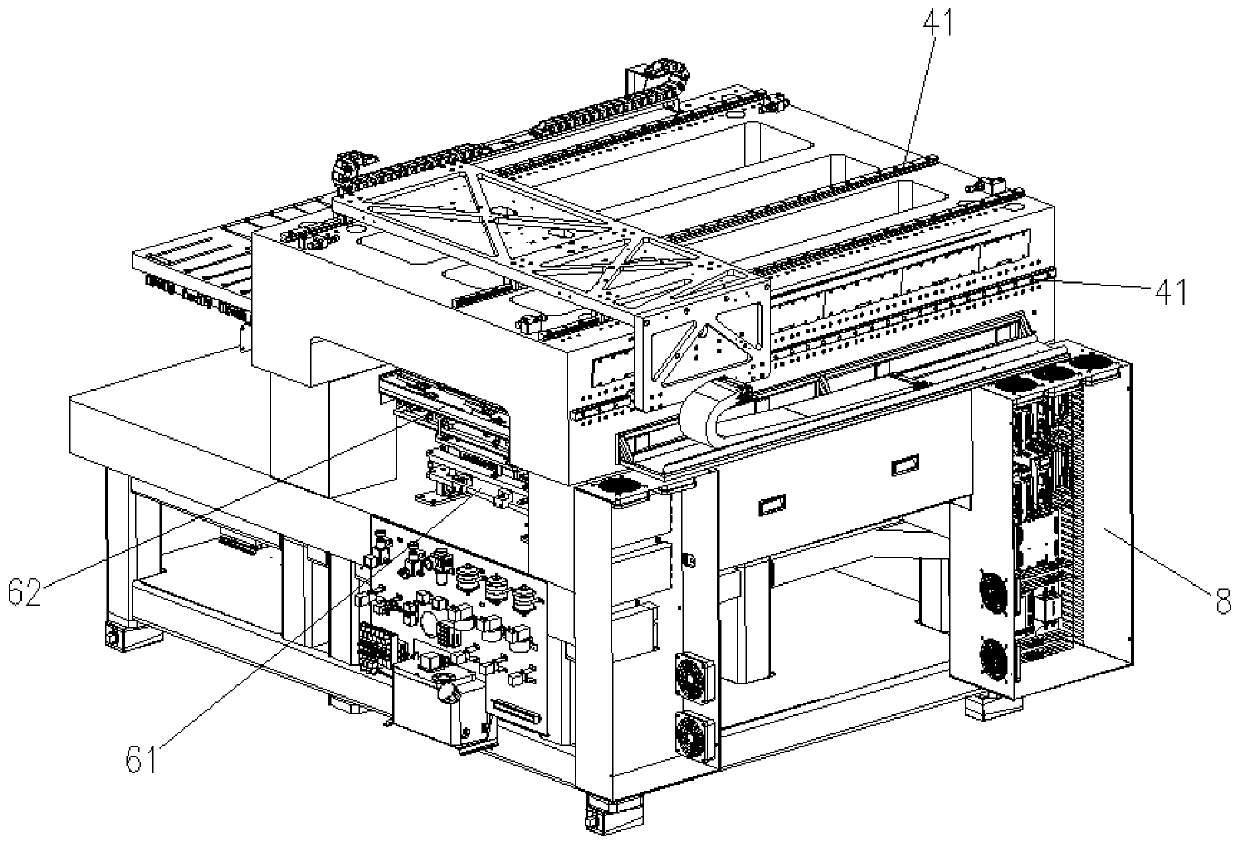

[0025] see Figure 1 to Figure 4 , the present invention provides a single-table inkjet machine for large sheets, comprising: a machine assembly 1, a printing table assembly 2, a CCD alignment system 3, an inkjet printing trolley assembly 4, a platen device 5, and nozzle cleaning Device 6, ink supply system 7 and control system 8.

[0026] The machine platform assembly 1 comprises: a frame 11, a base plate 12 arranged on the frame, a frame beam 13 arranged at the rear end of the base plate 12, the four corners of the frame beam 13 are supported by four columns 14 On the substrate 12, the substrate 12 is a marble substrate.

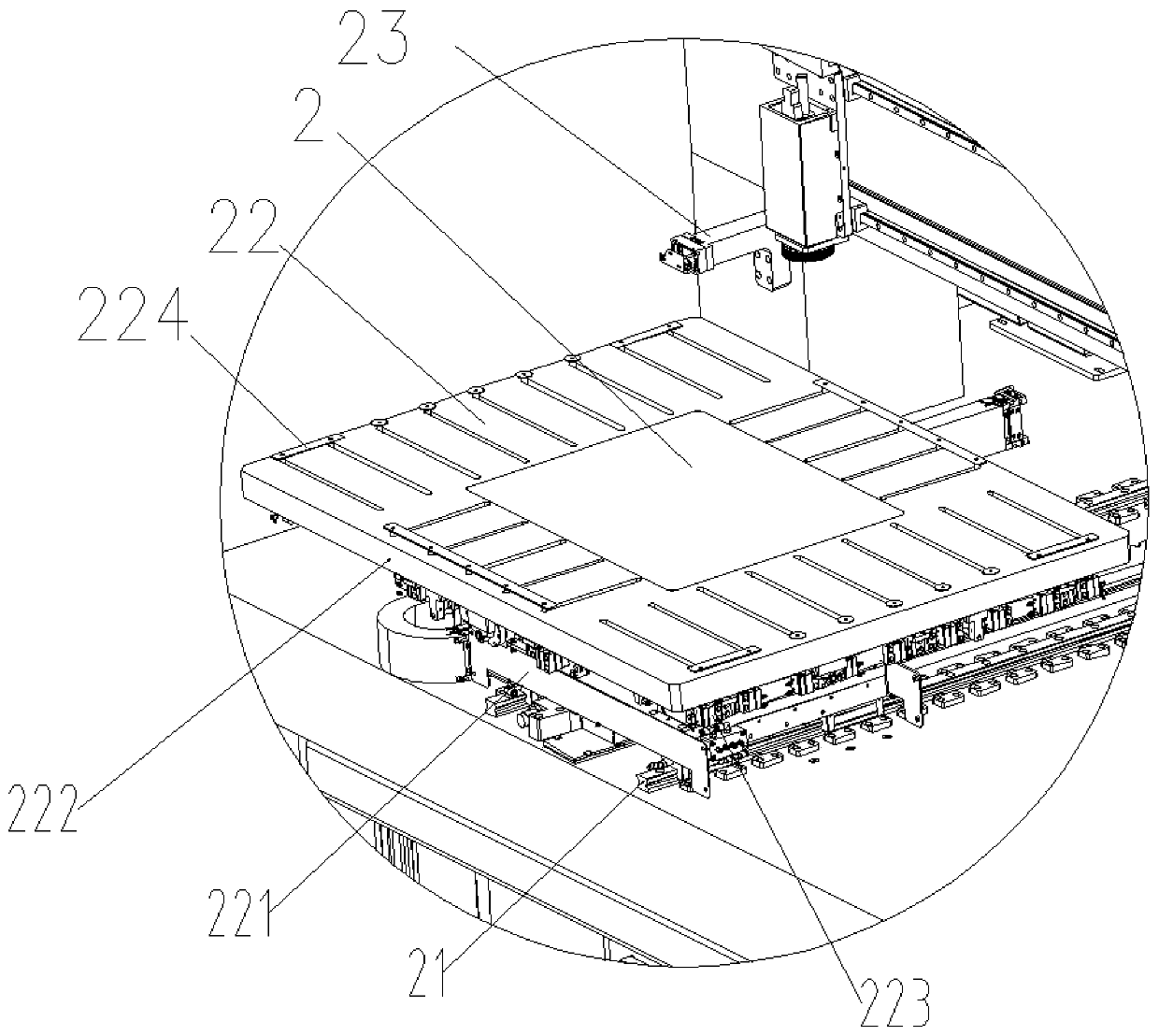

[0027] The printing table assembly 2 is arranged on the base plate 12, which includes: a Y-guiding rail 21 arranged on the base plate 12, a Y-direction slider arranged on the Y-guiding rail 21, and a Y-direction slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com