Method for producing electrical discharge copper matrix tool electrode for steel cavity mould

A tool electrode and manufacturing method technology, applied in electrode manufacturing, manufacturing tools, electric machining equipment, etc., can solve the problems of complex processing, inability to cut, difficult, etc., and achieve the effects of stable physical properties, improved efficiency, and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

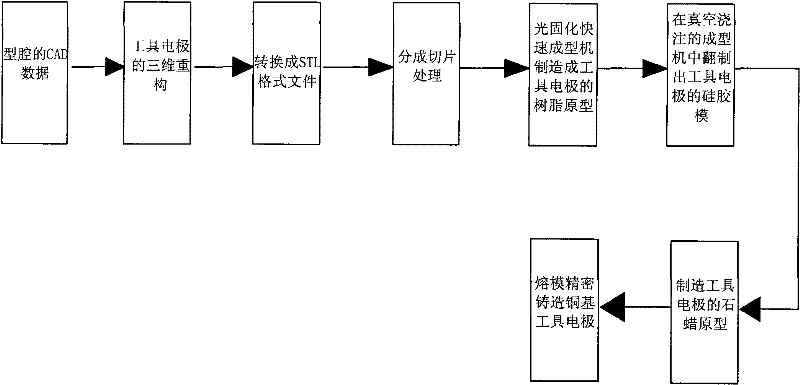

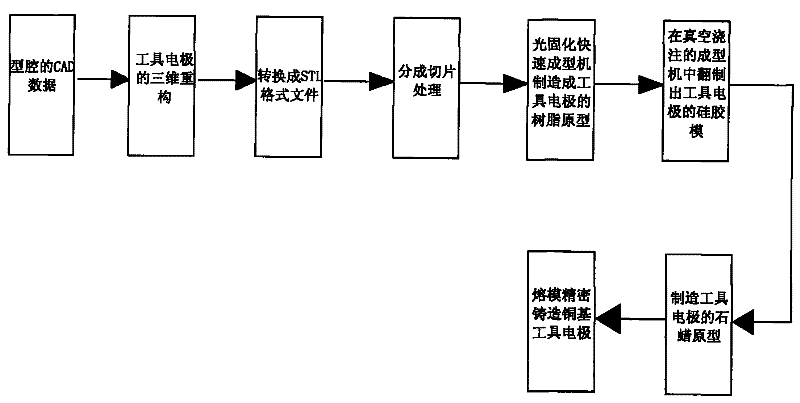

[0029] See attached picture, such as figure 1 Steps shown:

[0030] 1) Using CAD drawing software to realize the three-dimensional reconstruction of the tool electrode;

[0031] 2) Convert the above-mentioned three-dimensional reconstructed entity data into STL format files, and generate the default format file of the light-curing rapid prototyping equipment through Rpdata software layered slice processing, and input it into the light-curing rapid prototyping equipment;

[0032] 3) The light-curing rapid prototyping equipment receives the input instructions and manufactures the required resin prototype of the EDM tool electrode of the steel cavity mold;

[0033] 4) Put the resin prototype of the tool electrode obtained in the above steps into a vacuum casting molding machine, and turn out the silicone mold of the tool electrode;

[0034] 5) cast the paraffin prototype of the tool electrode with the silica gel mold produced in the above steps;

[0035] 6) Using the investmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com