Bamboo chip polishing equipment for bamboo summer sleeping mat

A technology of bamboo chips and mats, which is applied in the field of grinding equipment for bamboo mats and bamboo mats. It can solve problems such as the inability of the conveyor belt to achieve effective limit orientation, the thickness of bamboo chips, the influence of surface quality, and the instability of the grinding amount, so as to ensure stability. and uniformity, reducing the warping of bamboo pieces, and improving the supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

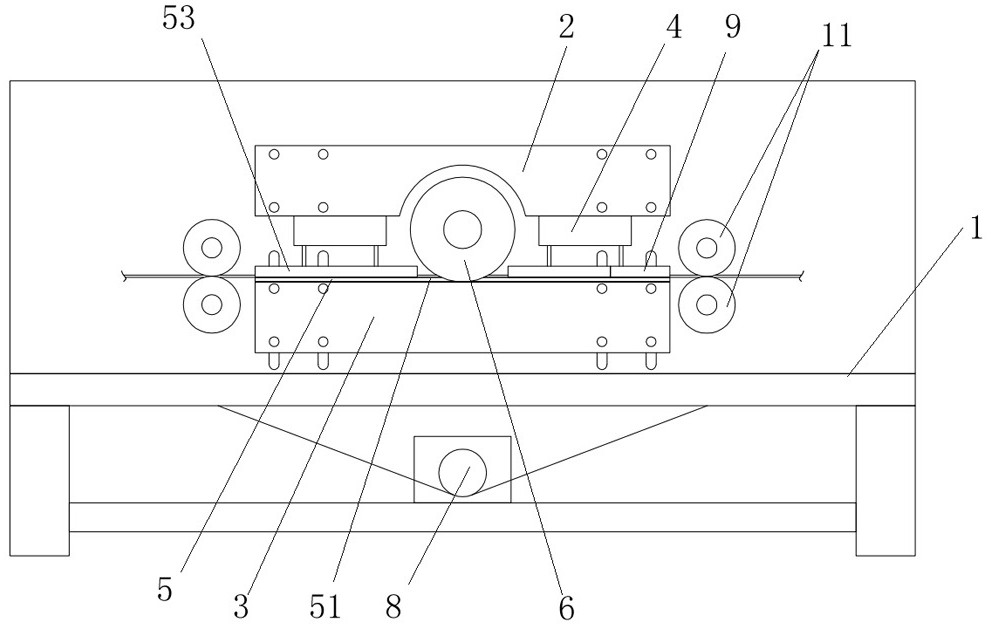

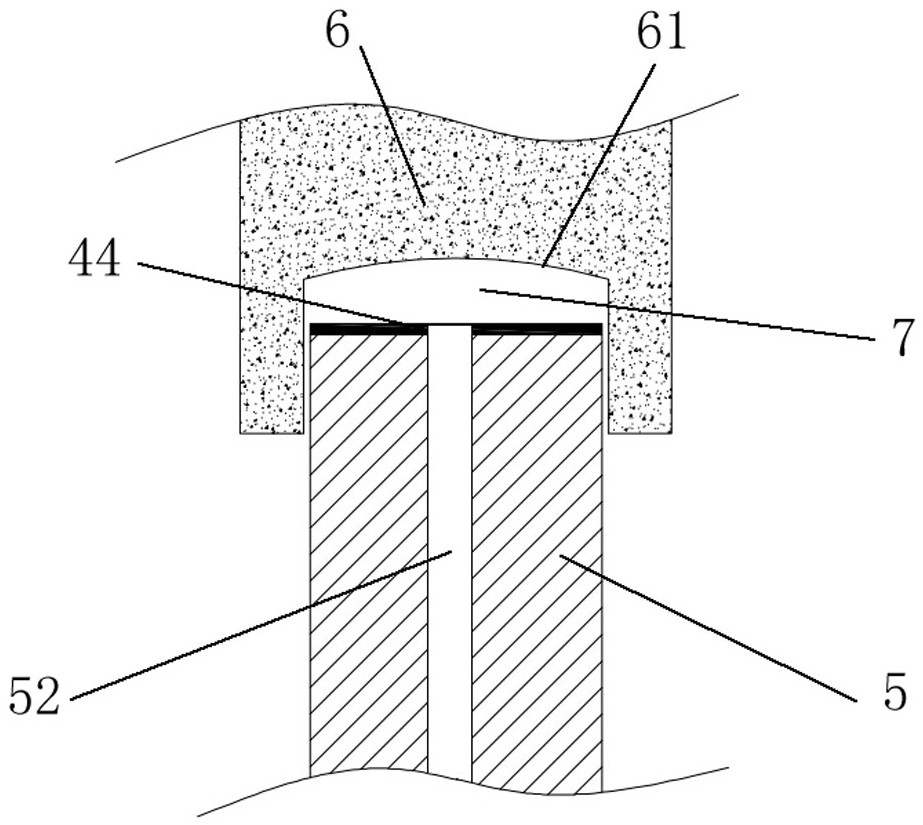

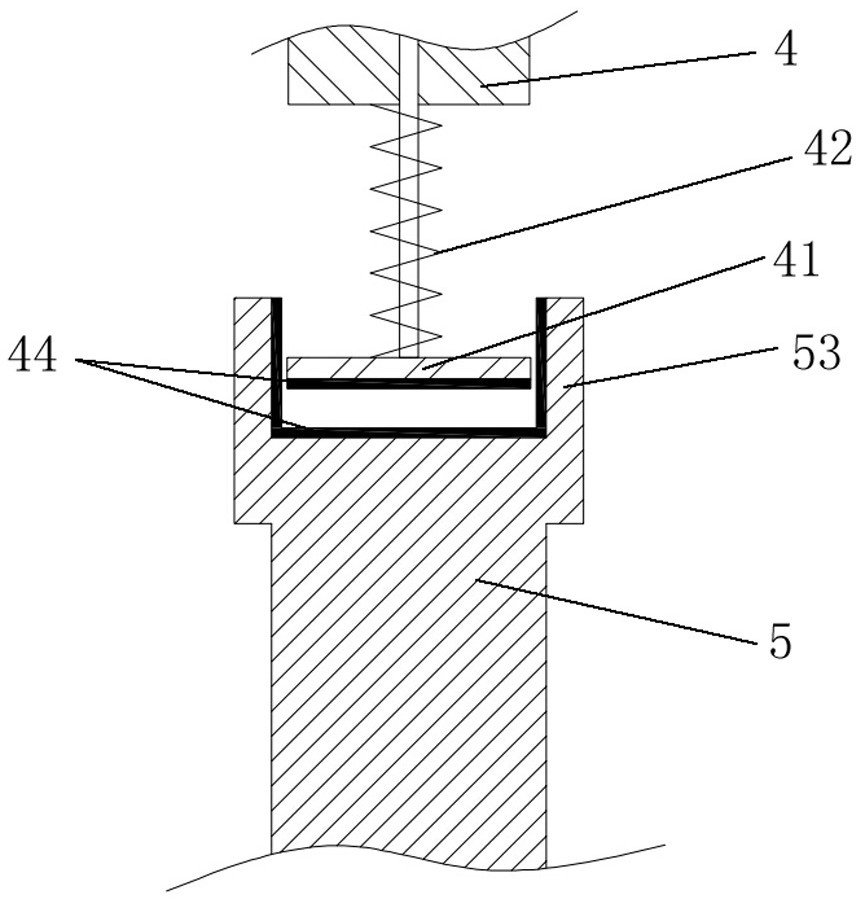

[0029] like Figure 1-6 A kind of bamboo mat bamboo chip polishing equipment shown, comprises support 1 and is located on support 1 and is the upper base 2 and the lower base 3 that are opposite up and down, wherein support 1 comprises at least as figure 1 A vertical plate that is used to install various parts shown in the present embodiment selects the tabletop stand as the foundation of this vertical plate in the present embodiment, can be the foundation of other forms in other preferred embodiments, upper base 2 and The lower base 3 is installed on the vertical plate through bolts, and the lower base 3 cooperates with the vertical holes on the vertical plate to realize the connection and the adjustable position in the height direction (its position adjustment is to adjust the height of the grinding space) . The opposing surfaces of the upper base 2 and the lower base 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com