Apparatus for studying electrochemical behavior of material corrosion, and in-situ TEM method thereof

A technology for studying materials and electrochemistry, applied in the field of devices for studying the electrochemical behavior of corrosion of materials, to achieve the effect of corresponding observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

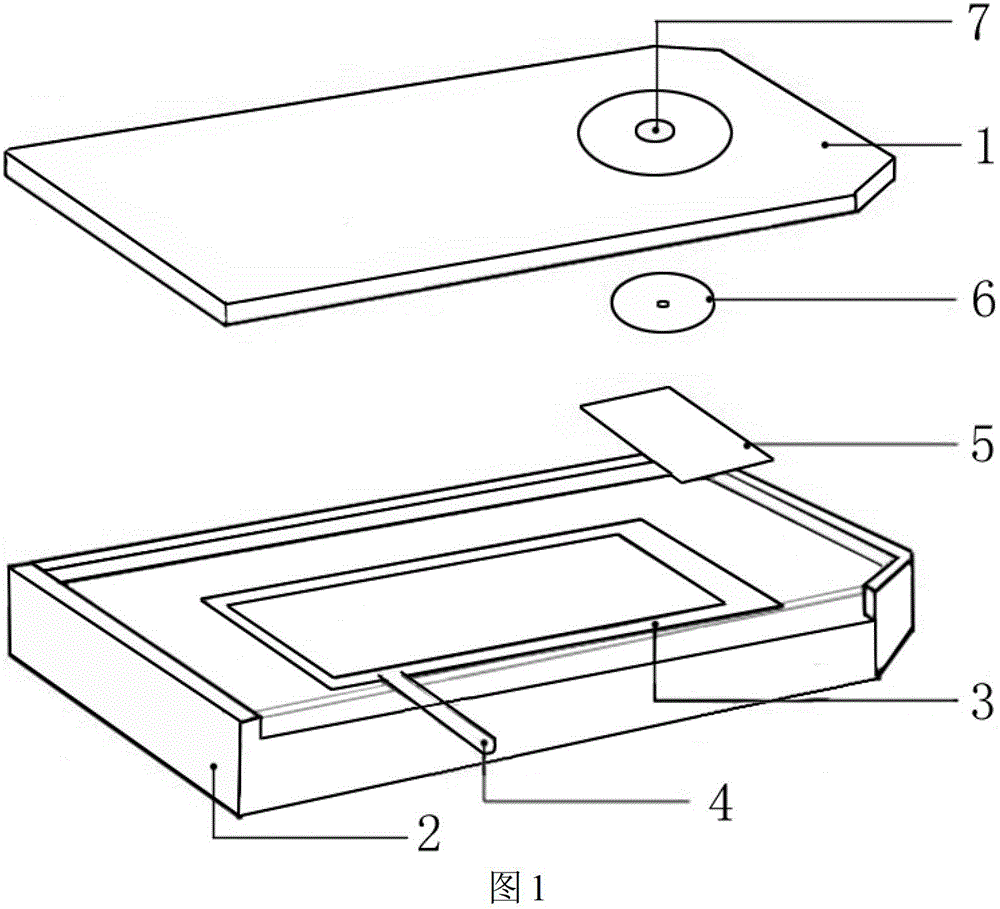

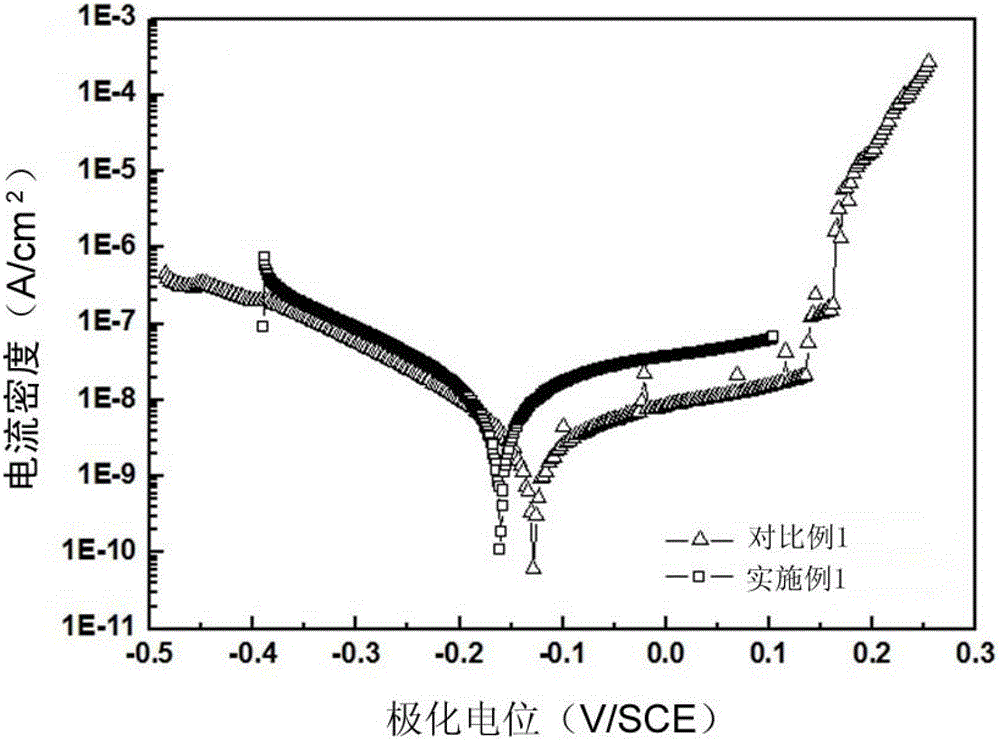

[0026] Cut a 316F cold-rolled stainless steel rod with a diameter of 10mm (Nippon Steel Corporation, Japan) into thin slices with a length of 1 cm and a thickness of about 300 μm in the axial direction, and grind the thin slices to about 120 μm with SiC sandpaper with a particle size of 2000. The hole is punched into a disc with a diameter of 3 mm, and it is ground to about 30 μm, and then polished, pitted, and ion-thinned to make a TEM sample, and then used such as figure 1 The fixture shown is packaged as an electrode, the working electrode. Configure 0.5mol / L NaCl solution, the test solution is kept at 28°C by a constant temperature water bath, and the packaged sample is tested for the potentiodynamic polarization curve in the solution, and the test is stopped when the transient current peak does not appear on the curve. Test results such as figure 2 shown. The sample after the polarization test was removed from the fixture, soaked in absolute ethanol to remove the resid...

Embodiment 2

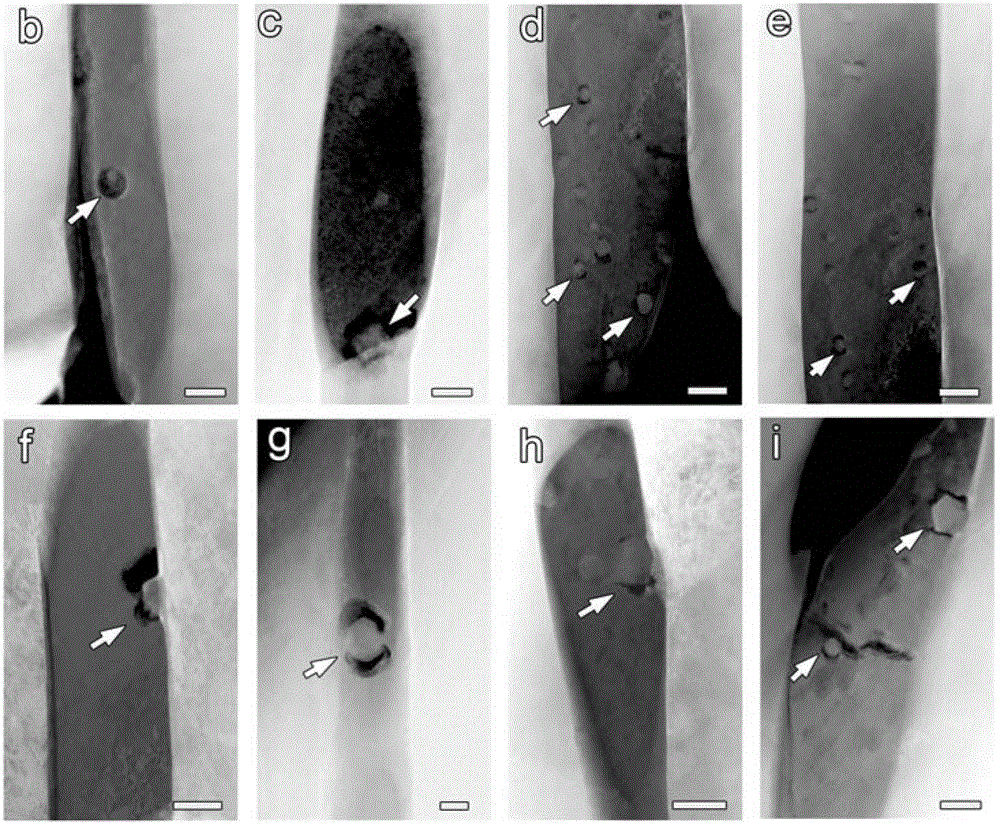

[0031] Solution preparation, electrode packaging, and subsequent processing are the same as in Example 1. Conduct potentiodynamic polarization curve test on TEM sample in 0.5mol / L NaCl solution, stop polarization test when transient current peak appears on the curve (such as Figure 4 shown), and then observed by TEM, the obtained HAADF-STEM morphology is as follows Figure 5 (b~f) shown. The results show that at this time, the MnS inclusions are severely dissolved, and the dissolution has extended to the stainless steel substrate, forming corrosion pits with a size of 1~2um, that is, metastable pits, indicating that the anode corresponding to the passivation interval of the polarization curve The transient current peak is the process of metastable pitting corrosion. In previous studies, due to the limitation of the spatial resolution of the observation means, it has been controversial whether the corrosion process corresponding to the transient current peak is the dissoluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com