Crank type elevator with small operation area

A small-area, curved-arm technology, applied in the direction of the lifting device, can solve problems such as the collision between the support arm and the bracket, the inability to achieve effective lifting, and the inability to meet the working space, etc., to achieve reduced volume, good buffer protection effect, and convenient movement The effect of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

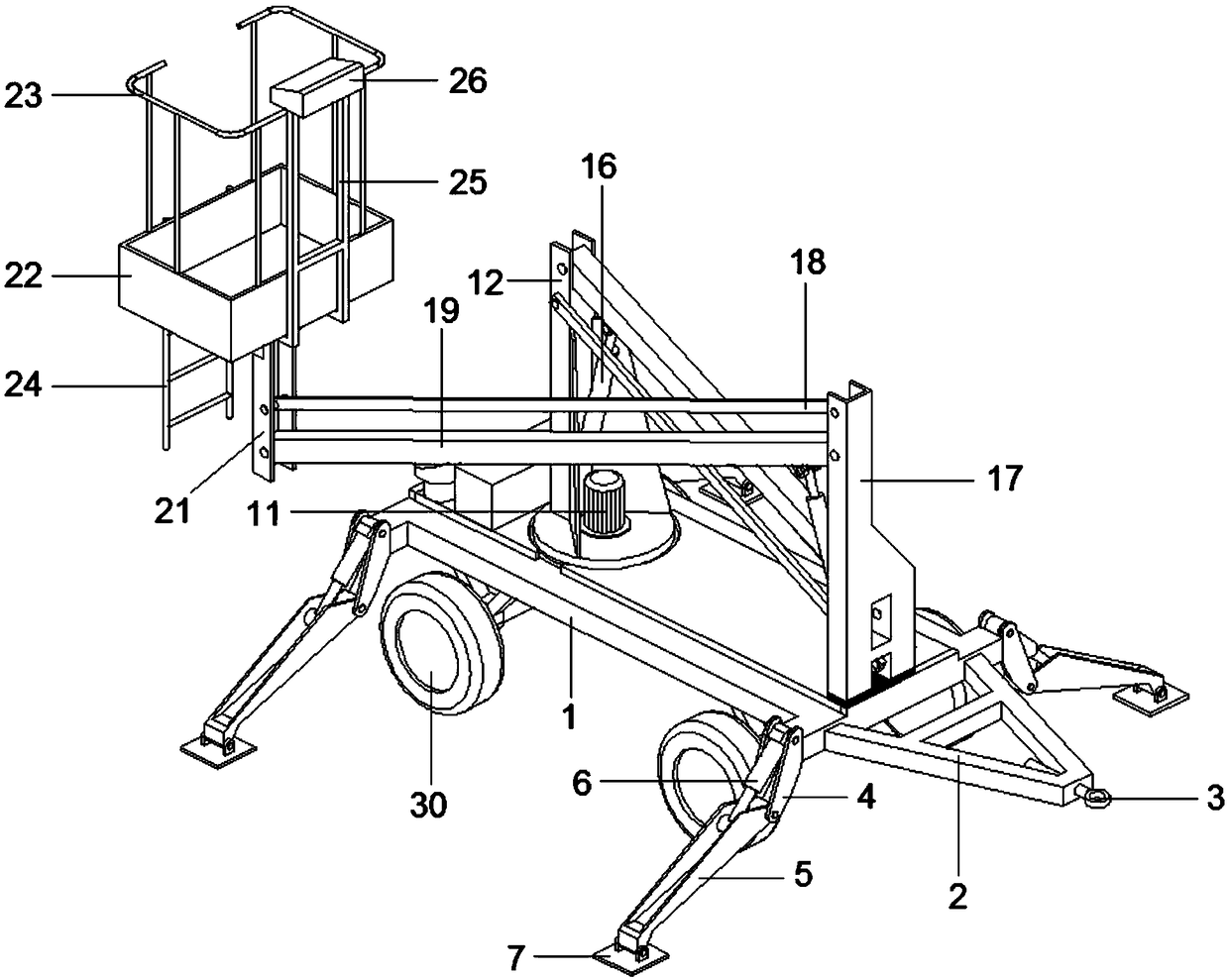

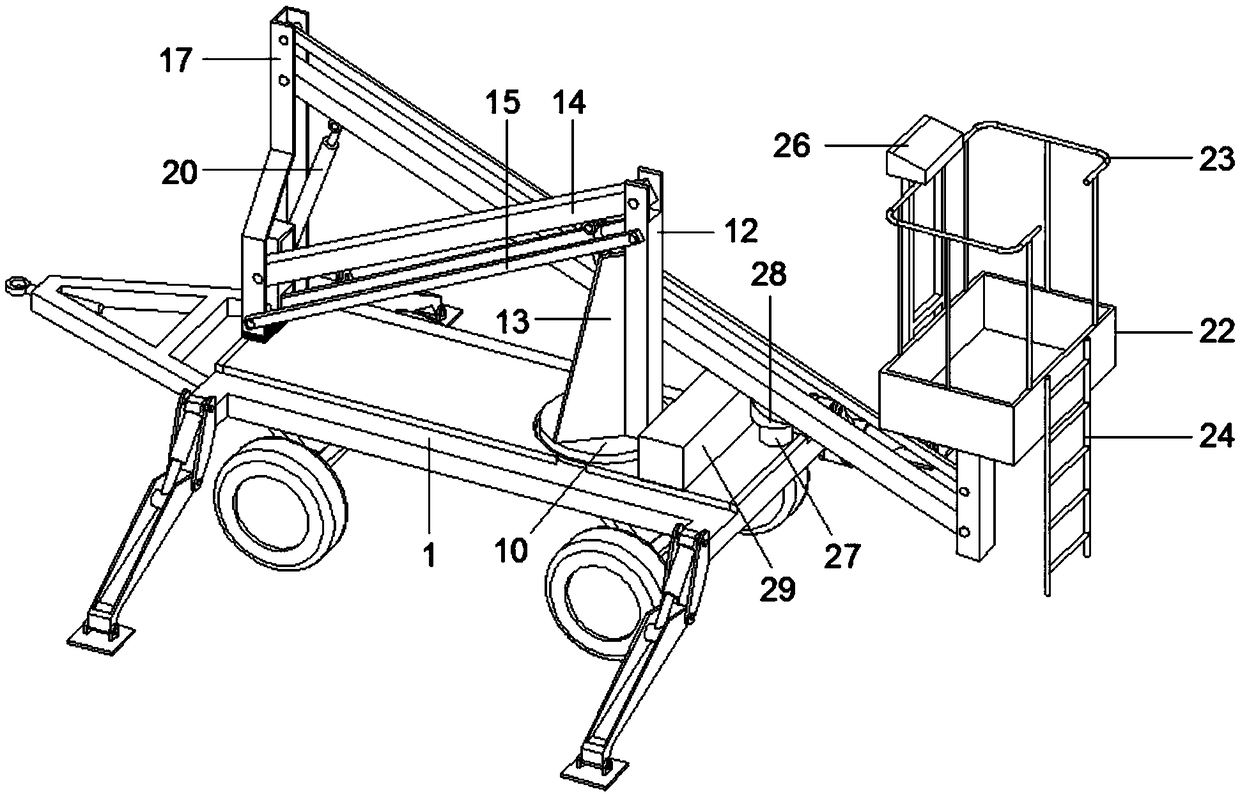

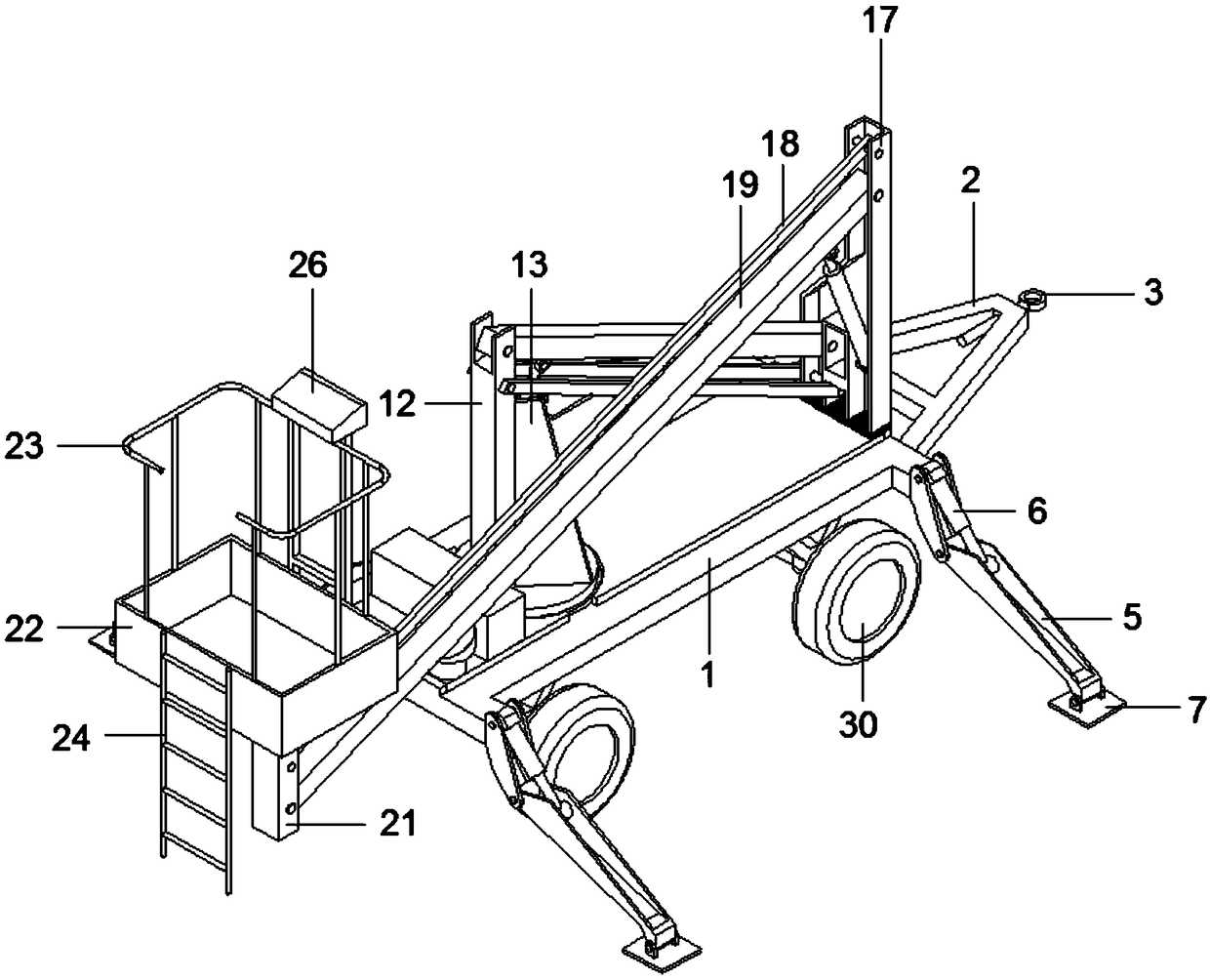

[0030] A curved arm lift with a small working area, comprising: a base 1, a trailer 2, a hanging ring 3, a side bracket 4, a supporting leg 5, a first oil cylinder 6, a foot 7, a bottom beam 8, a transmission shaft 9, a rotating Platform 10, drive motor 11, support column 12, side baffle 13, first support arm 14, first connecting beam 15, second oil cylinder 16, bracket 17, second connecting beam 18, second supporting arm 19, third Oil cylinder 20, base 21, workbench 22, guardrail 23, ladder 24, console support 25, console 26, pad 27, spacer 28, hydraulic station 29, traveling wheel 30; There are four places arranged symmetrically on both sides, and the side bracket 4 is connected with the base 1 by welding to install the support leg 5, increase the distribution area of the support leg 5, and improve the support effect; the top of the support leg 5 is hinged to the side The bottoms of the bracket 4 are connected, and the feet 7 are mounted on the bottom of the support legs 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com