Meat chopping machine

A technology of stuffing machine and refrigerator, which is applied in the field of stuffing processing, which can solve the problems of stuffing quality impact, stuffing taste decline, and inability to stuff stuffing, so as to improve product quality, improve product grade, and prolong shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

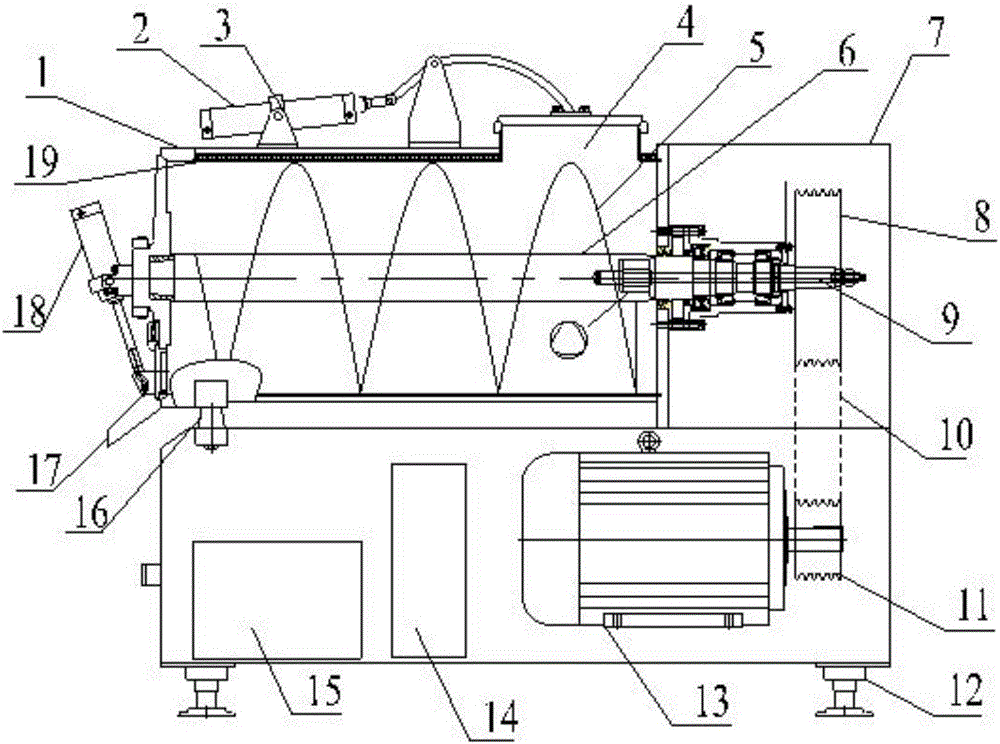

[0027] Such as Figure 1-3 As shown, this embodiment provides a stuffing machine, including a casing 7, a driving mechanism, a screw shaft 6, a tank body 1, a refrigerator 14 and a vacuum pump 15, and the tank body 1 is fixedly arranged on the top of the casing 7 and has a support plate 16 for Support, the top of the tank body 1 is provided with a feed port 4, and one side is provided with a discharge port. The tank body 1 is provided with a screw shaft 6, and the screw shaft 6 is fixedly connected with a helical blade 5, which is used to break up and mix the fillings. Stirring, one end of the screw shaft 6 is connected with the driving mechanism through the main transmission shaft 9, the driving mechanism, the refrigerator 14 and the vacuum pump 15 are all arranged in the shell 7, the inner wall of the tank body 1 is provided with a refrigeration space 19, and the refrigeration space 19 is connected with the refrigerator. 14 is connected to ensure that the temperature in the ...

Embodiment 2

[0030] Such as figure 1 -As shown, this embodiment provides a kind of stuffing machine, on the basis of embodiment one, the stuffing machine of this embodiment also has the following characteristics:

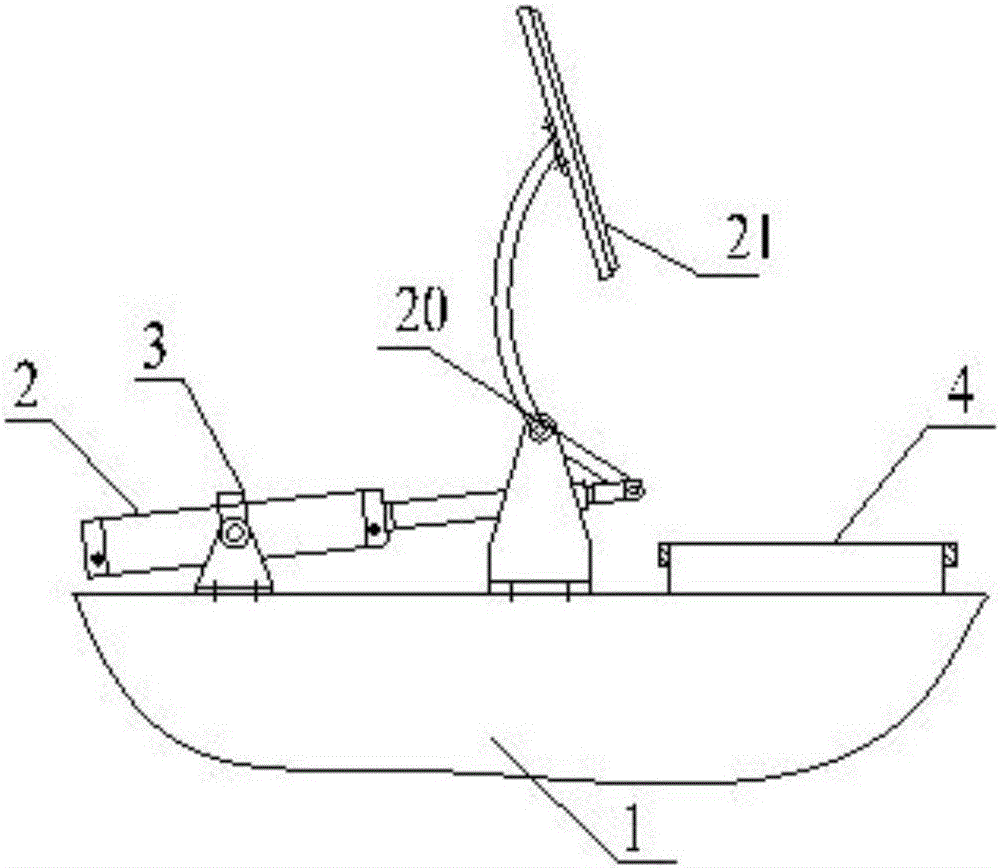

[0031] A feed door 21 is provided at the feed port 4, and a support is provided on the top of the tank body 1. The feed door 21 is connected with the rotating shaft 20 on the support through a connecting rod. The rotating shaft 20 is driven by the first cylinder 2, and the first cylinder 2 It is fixed by the first cylinder support 3; after the material is put into the feed port 4, the feed door 21 is controlled by the first cylinder 2 to close, so as to prevent the filling from splashing outward during the filling process.

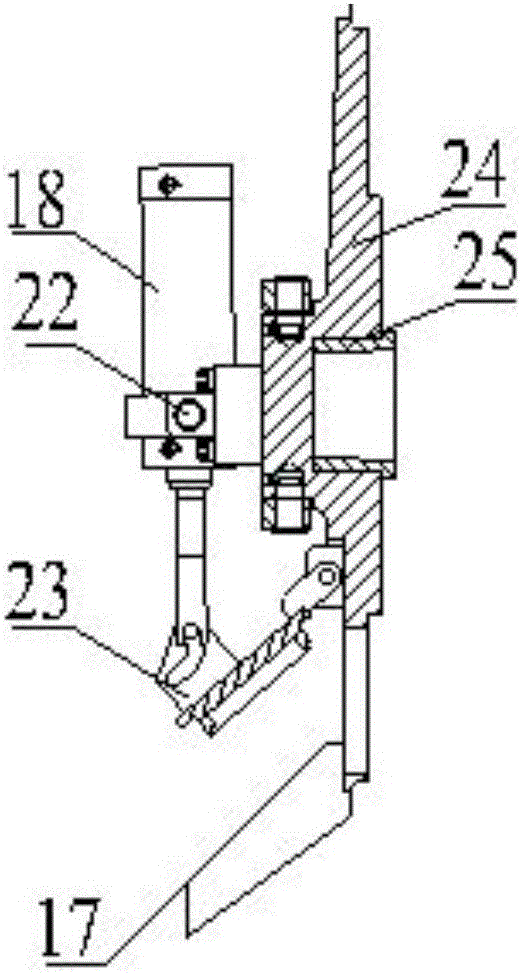

[0032] The discharge port is located at the bottom of the tank body door 24 of the tank body 1, and the discharge port is provided with a discharge door 23, which is driven by the second cylinder 18, and the second cylinder 18 is fixed by the second cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com