An Artificial Intelligence Compensation Method for Thermal Deformation Error of Machine Tool

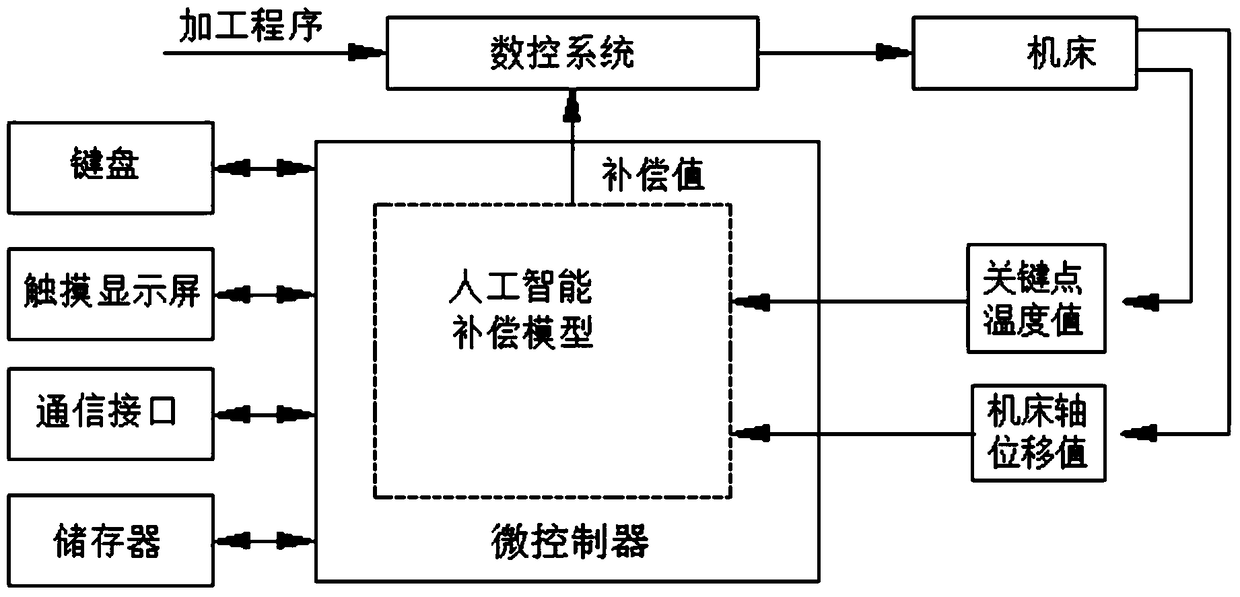

A thermal deformation error, artificial intelligence technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of real-time error compensation technology stay and other problems, achieve the effect of strong versatility, improve processing accuracy, and reduce thermal error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

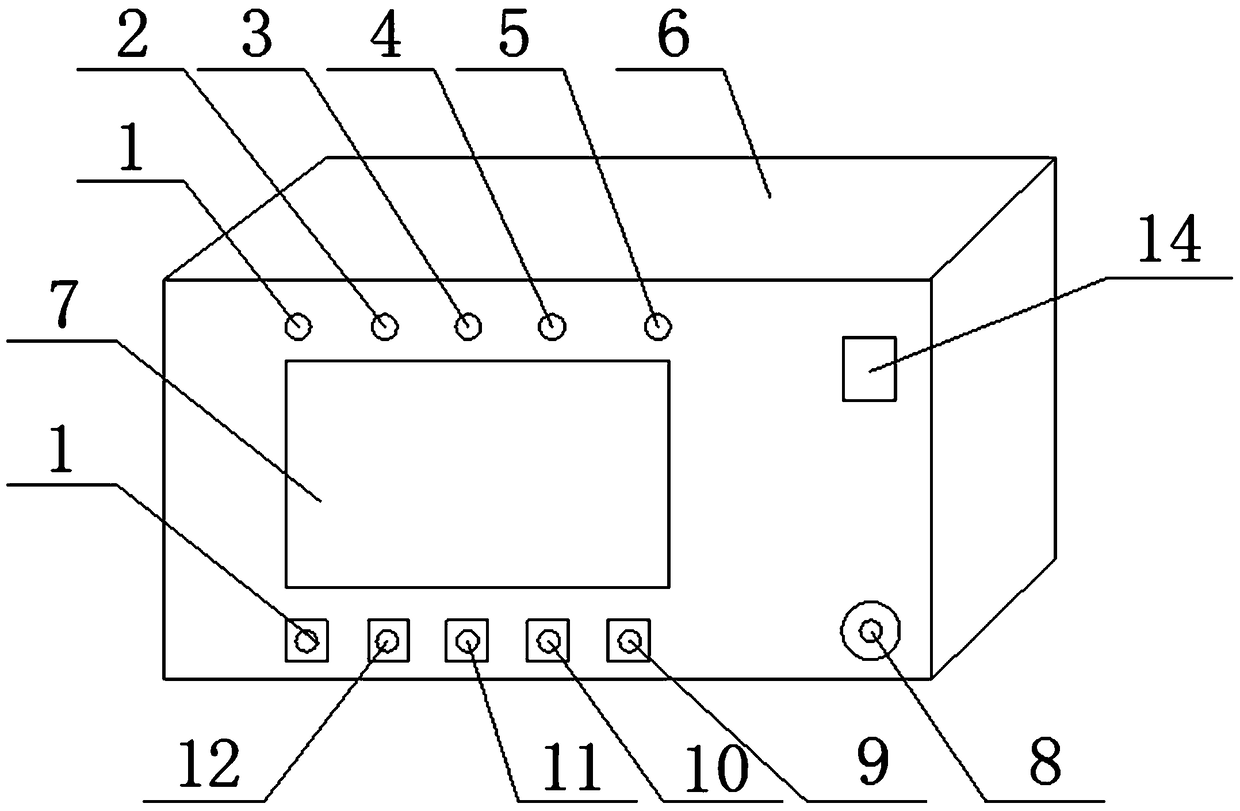

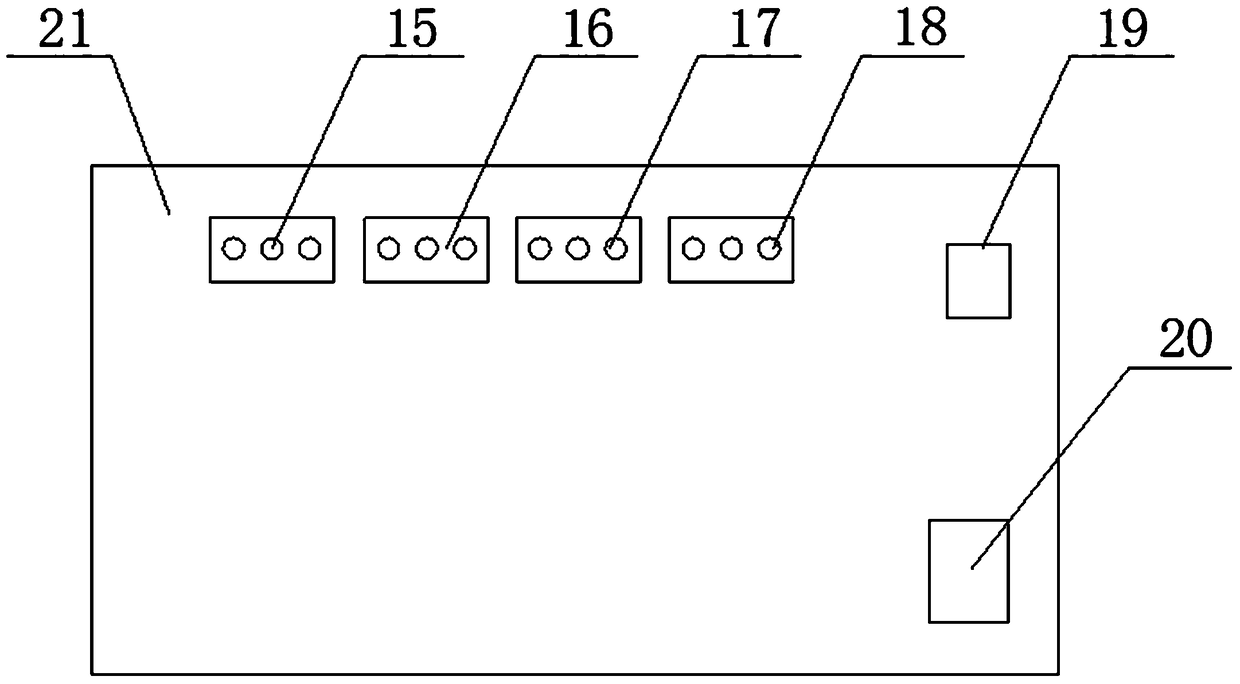

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] see figure 1 , figure 2 and image 3 , the present invention provides a thermal deformation error artificial intelligence compensator for machine tools, including a housing 6, a rear panel 21, a liquid crystal display 7, a temperature sensor interface group, an indicator light group, a compensator button group, a microprocessor and a memory, and the rear panel 21 is installed on the rear side of the housing 6, the liquid crystal display 7 is installed on the front of the housing 6, the housing 6 is located above the liquid crystal display 7 and is provided with an indicator group, and a compensator button group is provided below, and the rear panel 21 A temperature sensor interface group is arranged on the top, and the temperature sensor interface group, the indicator light group, the compensator button group and the storage are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com