False tooth machine tool thermal error online temperature compensation method

A processing machine tool and temperature compensation technology, which is applied in the field of denture processing for denture restoration, can solve problems affecting the accuracy of dentures and the positioning accuracy of denture restorations, and achieve the effect of thermal error compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

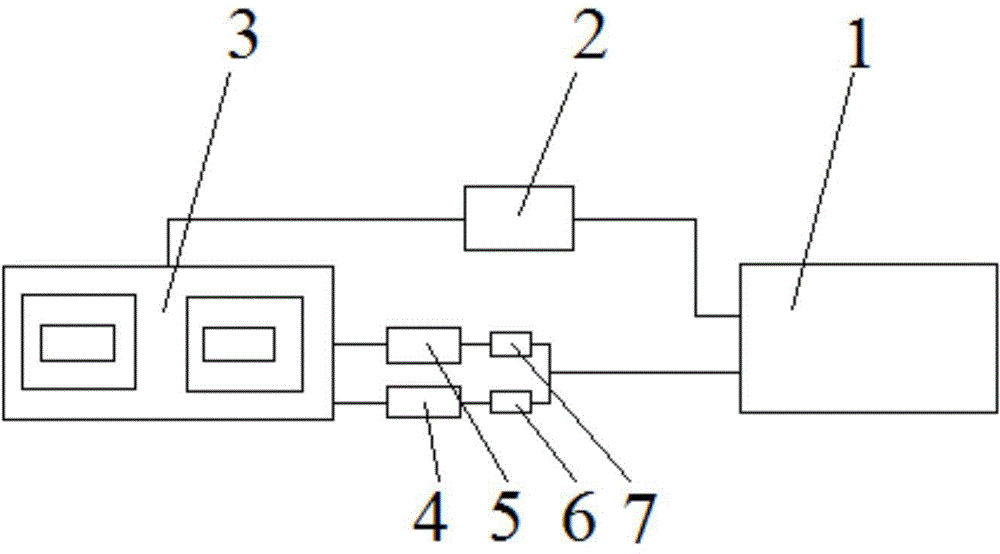

[0036] For the convenience of the following description, the following terminology is first explained:

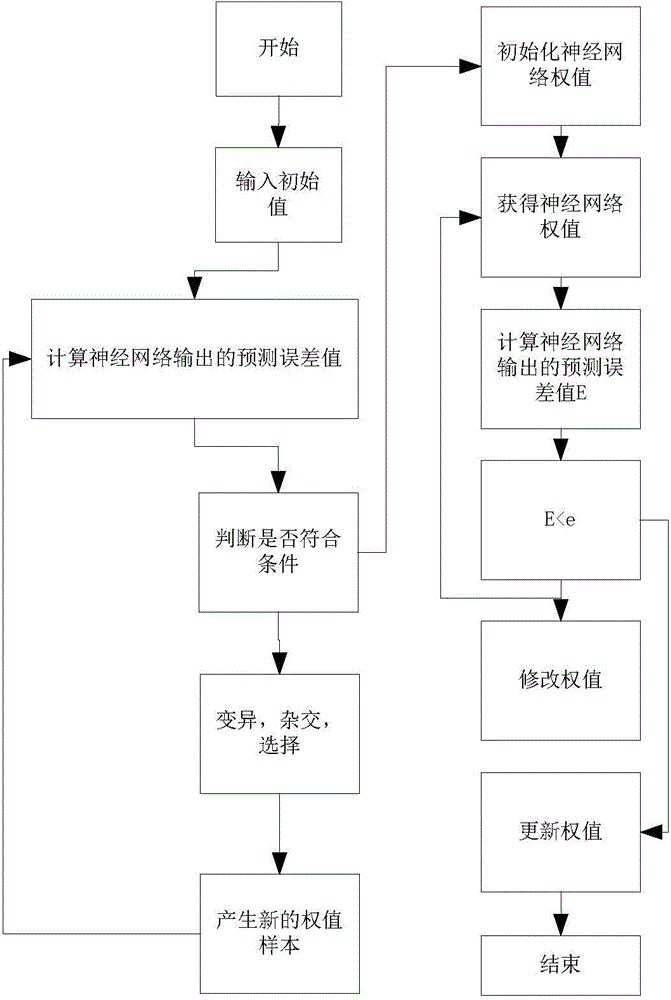

[0037] GA evolutionary algorithm: Geneticalgorithm evolutionary algorithm, genetic algorithm evolutionary algorithm, evolutionary algorithm based on genetic algorithm.

[0038] BPN neural network: Backpropagationneuralnetwork, backpropagation artificial neural network.

[0039] NC code: the code that can be recognized by the digital information control machine controller, that is, the code that can be recognized by the digital processing machine tool.

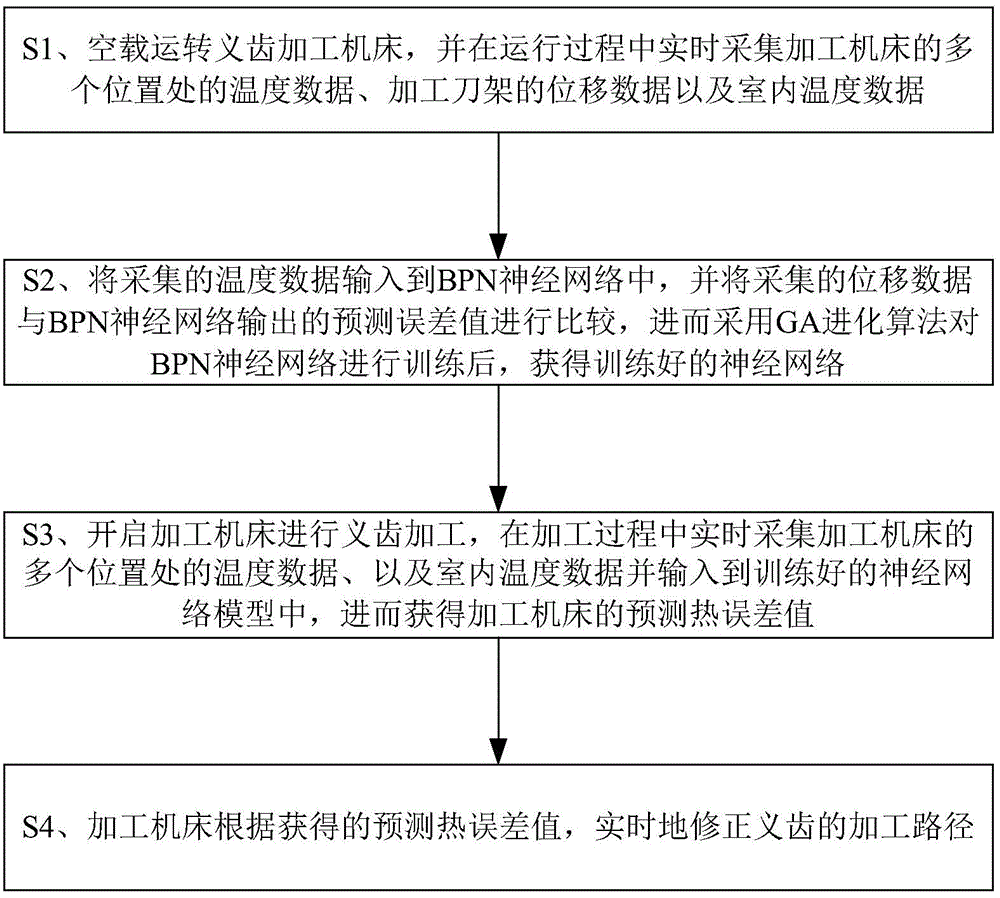

[0040] refer to figure 1 , the invention provides an online temperature compensation method for the thermal error of a denture processing machine tool, comprising:

[0041] S1. Run the denture processing machine tool without load, and collect the temperature data at multiple positions of the processing machine tool, the displacement data of the processing tool holder and the indoor temperature data in real time during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com