Pre-stressed continuous concrete beam design method based on BIM technology

A design method and prestressing technology, applied in the direction of design optimization/simulation, calculation, special data processing application, etc., can solve the problems that the design parameters cannot achieve information linkage, the basic data is not common, and the spatial relationship is scattered, so as to improve the design efficiency. And the effect of the quality of the results, the strong practicability and the high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

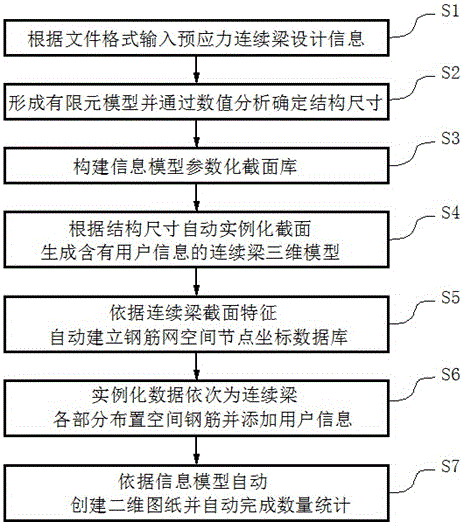

[0030] Such as figure 1 As shown, a design method of prestressed concrete continuous beam based on BIM technology includes the following steps:

[0031] (ⅰ) Input prestressed continuous beam design information S1 according to the file format

[0032] According to the design requirements of continuous beams, fill in the preliminary finite element calculation information such as structural dimensions, prestressed steel beam data, boundary conditions and loads according to the established data input format.

[0033] (ii) Form a finite element model and determine the structural size S2 through numerical analysis

[0034] Read all kinds of design information input in step (i), rely on the conventional prestressed concrete continuous beam simulation analysis software, establish a finite element analysis model, and complete the numerical analysis and checking of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com