High-speed train shaft-mounted brake disc

A technology for high-speed trains and brake discs, applied in the direction of brake discs, brake types, brake components, etc. Problems such as the broken bolts of the brake disc mounted on the shaft assembly have achieved the effect of improving the core competitiveness of the product, shortening the delivery cycle, and facilitating localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

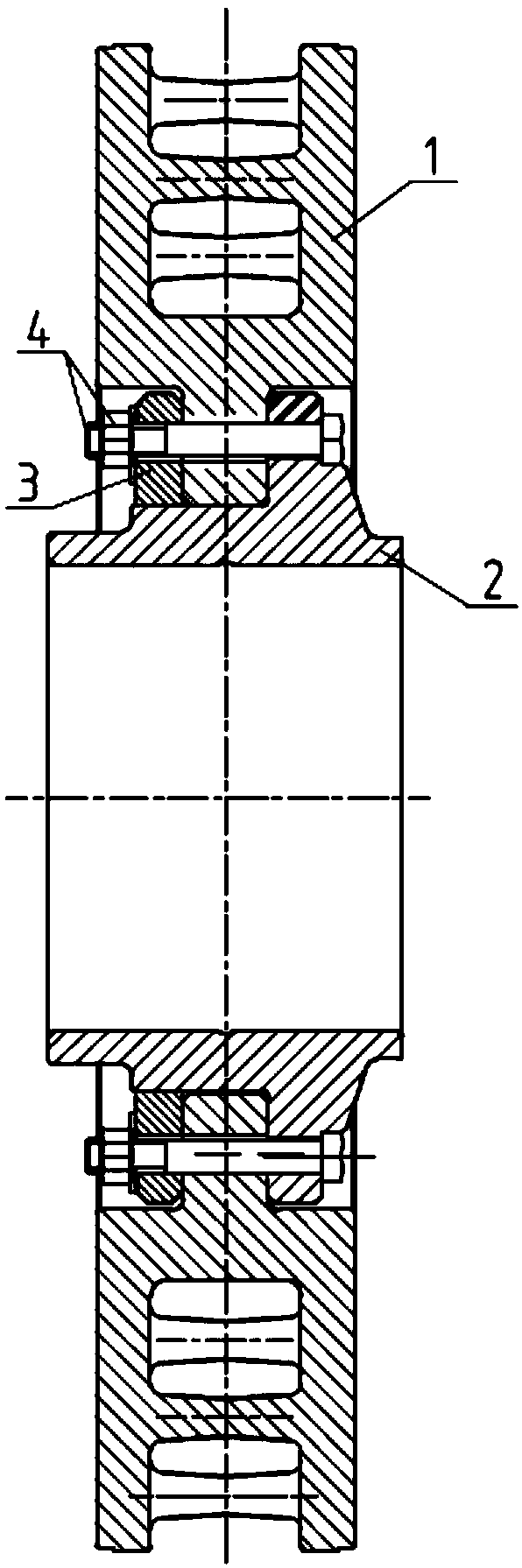

[0033] Such as figure 1 As shown, the shaft-mounted brake disc of a high-speed train includes: a welded disc body 1, a disc hub 2, a pressure ring 3 and 9 sets of fasteners 4.

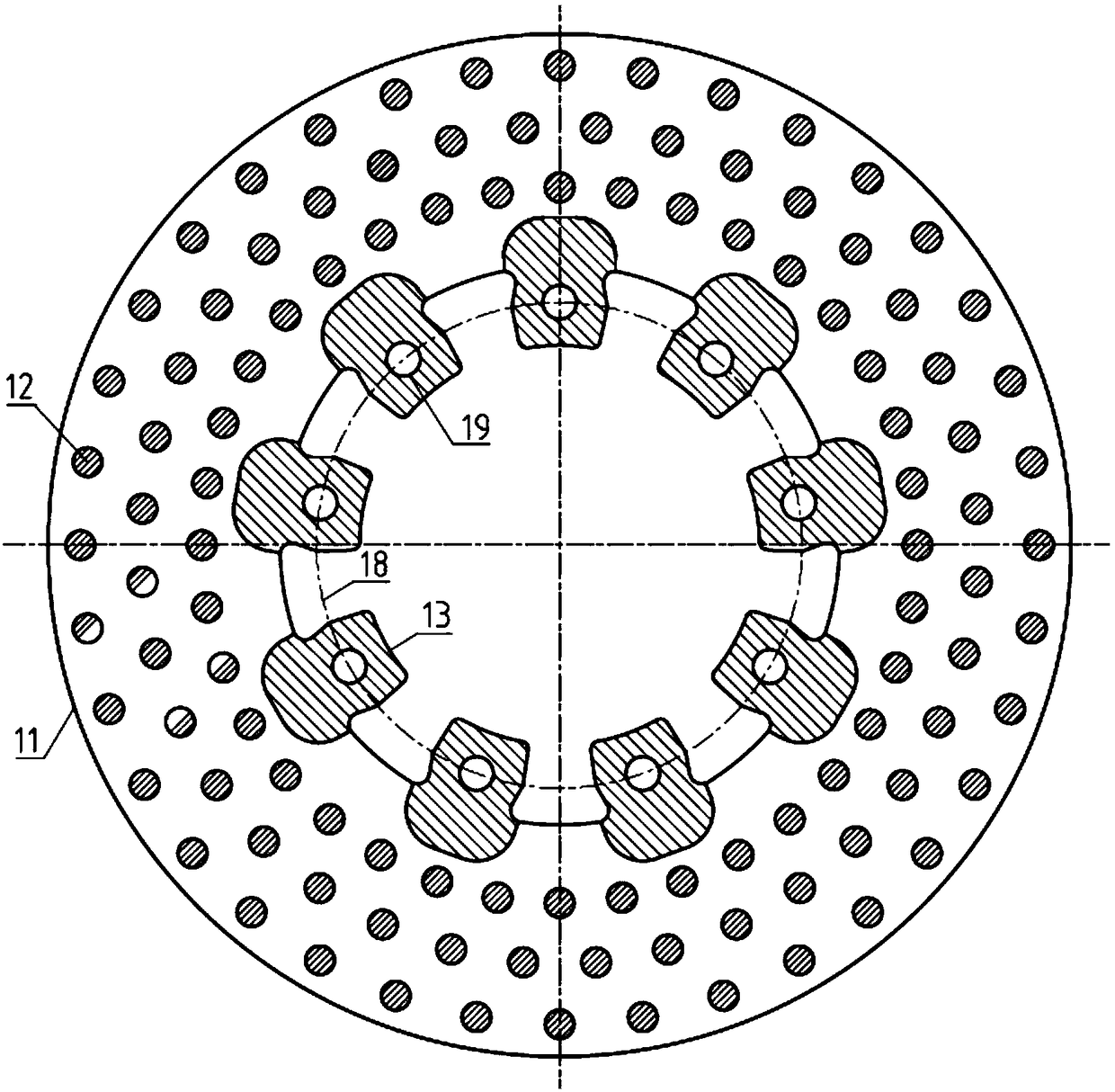

[0034] refer to figure 2 and Figure 5 The welding disc body 1 includes 2 friction rings 11, a plurality of heat dissipation ribs 12 and 9 disc body flange teeth 13 with bolt holes in the middle of the equicircumferential distribution; the outer ring of the equicircumferential distribution is processed on one side of the friction ring 11 The heat dissipation rib groove 14, the middle ring heat dissipation rib groove 15, the inner ring heat dissipation rib groove 16 and 9 flange tooth grooves 17, the groove depth is consistent and the depth is 1mm to 2mm, the outer ring heat dissipation rib groove 14 The number is not greater than the number of cooling rib grooves 15 in the middle ring, the number of cooling rib grooves 15 in the middle ring is not greater than the number of cooling rib grooves 16 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com