Automatic edge sealing process for vacuum glass

A vacuum glass and glass technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems that restrict the wide application of vacuum glass, affect the wide use of vacuum glass, hinder the development of vacuum glass, etc., and achieve self-extraction The effect of reliable air sealing, eliminating hidden dangers of air leakage, and improving the overall quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

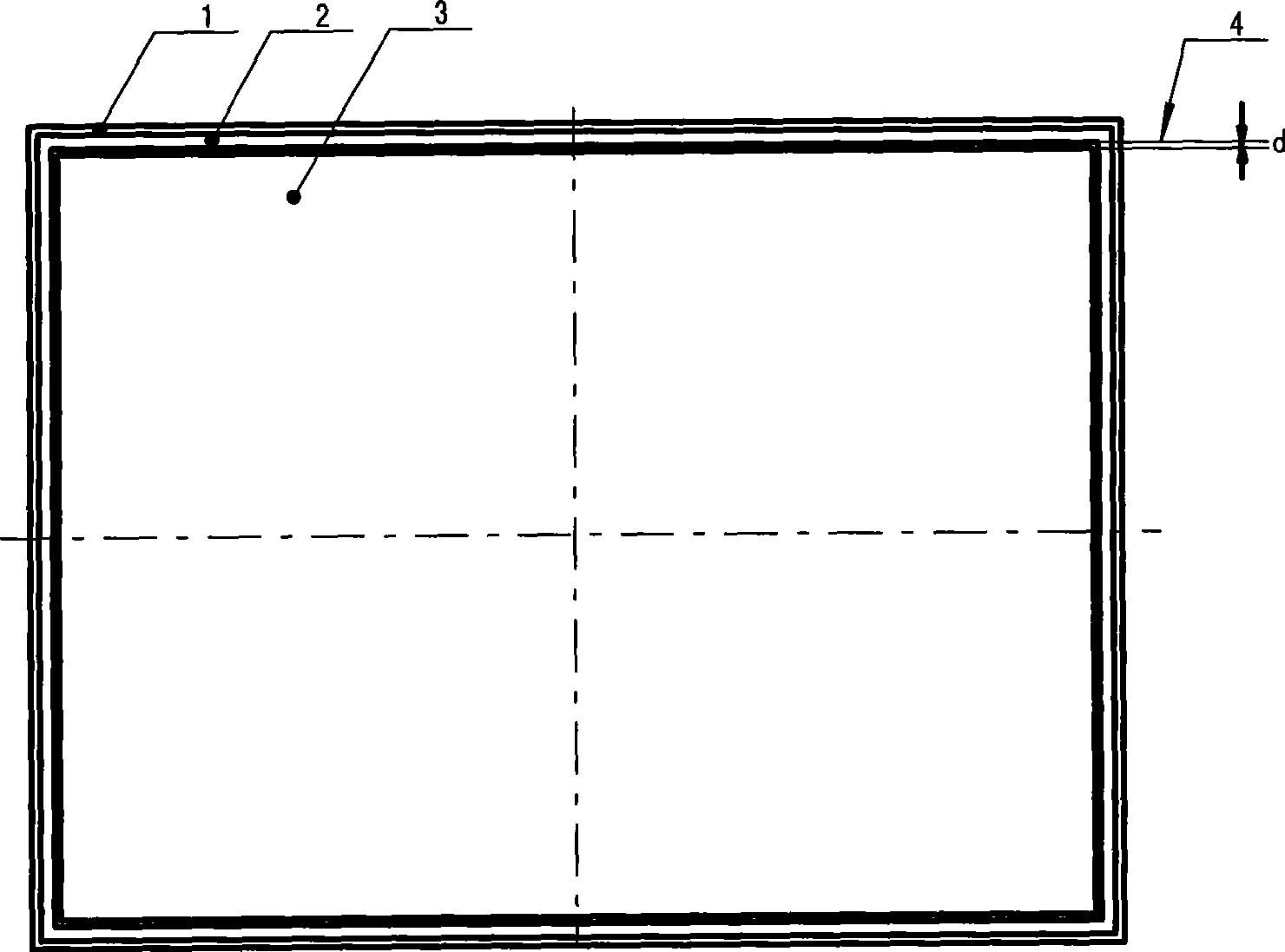

[0028] Example 1: see figure 1 , Figure 4 , Figure 5 , Image 6 .

[0029] An automatic vacuum glass edge sealing process, including setting a support on the base glass 1, placing the upper glass 3 on the base glass, sealing the edge with low-melting glass powder between the upper glass and the base glass, and putting it into a vacuum Heating in the heating furnace, taking out to obtain finished vacuum glass products. In this embodiment, in the step of edge sealing with low-melting-point glass frit between the top glass and the substrate glass, the top glass is placed on the substrate glass and leaves an edge on the substrate glass, and the low-melting-point glass powder strip or powder 2 Placed on the substrate glass and leave a gap 4(d) with the upper glass, the gap is used for escaping air; and after the low-melting point glass powder strip is melted in the heating furnace, the gap is fused by itself and passed through the The suction effect is sucked between the upp...

Embodiment 2

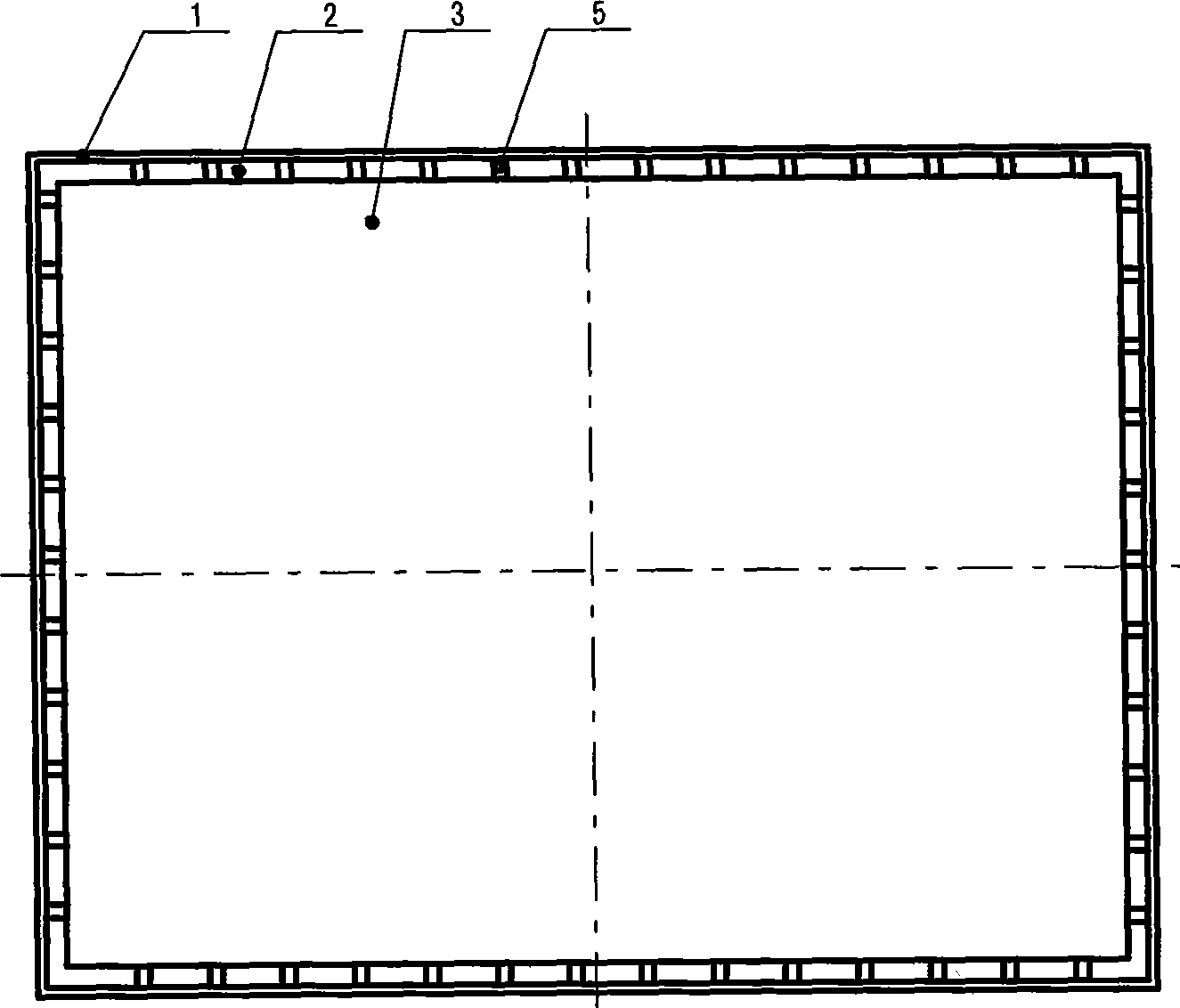

[0030] Example 2: see figure 2 , Figure 7 , Figure 8 , Figure 9 . In this embodiment, the same thing as Embodiment 1 is that the top glass is placed on the substrate glass, an edge is left on the substrate glass, and the low-melting point glass powder strip is placed on the substrate glass. The difference is: 1. The low-melting point glass powder strip is closely attached to the upper glass without leaving a gap; 2. The low-melting point glass powder strip is made like Figure 7 Represented semicircular groove 5, the semicircular groove communicates with the cavity formed between the upper glass and the substrate glass, or as Figure 8 Shown in the low-melting point glass powder type bar, be shaped on the circular through-hole 6 that communicates with the cavity formed between the upper sheet glass and the substrate glass; Figure 9 As shown, the low-melting point glass powder type bar is made into discontinuous section 7, and the discontinuous section is used to esca...

Embodiment 3

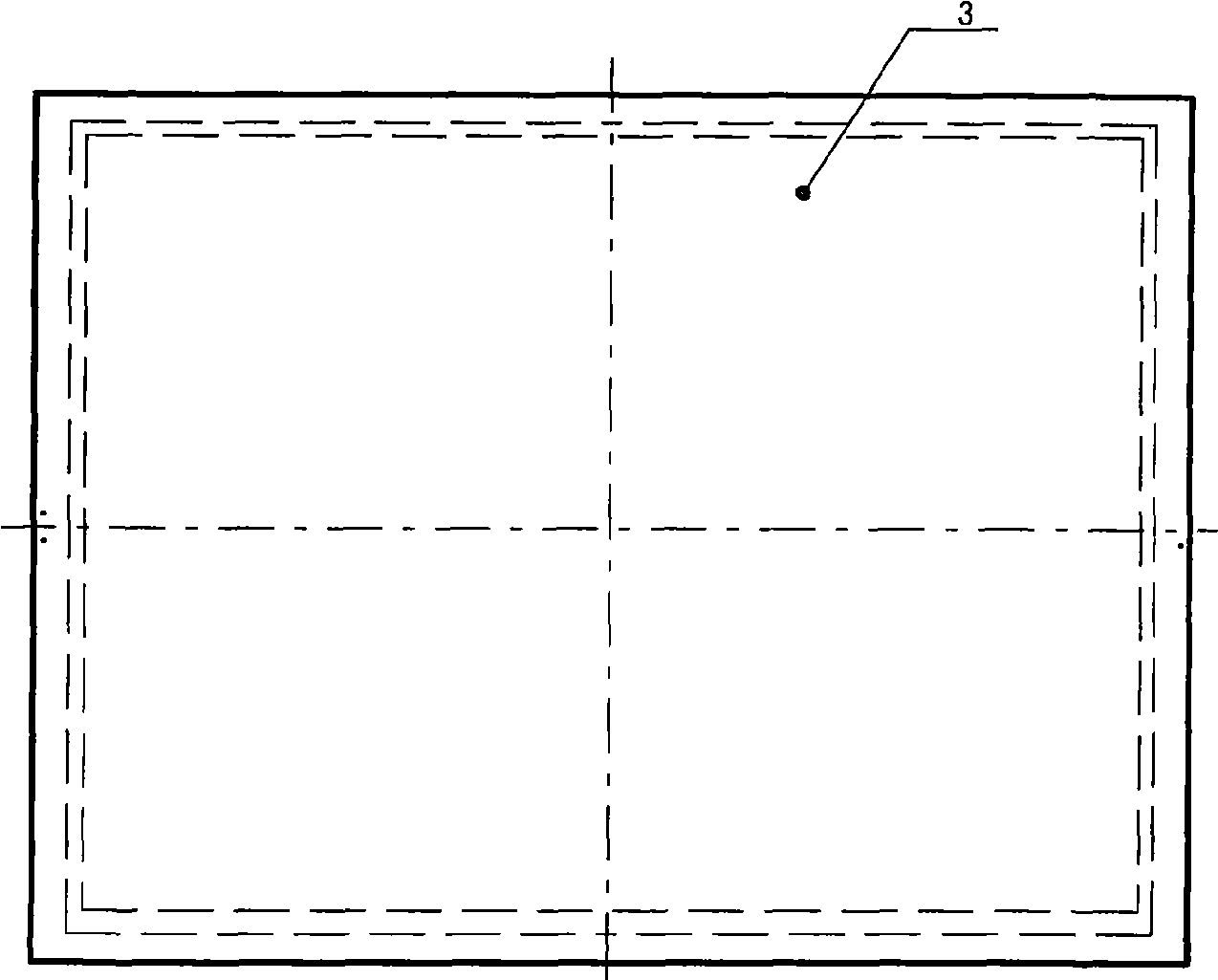

[0031] Embodiment 3: see image 3 , Figure 10 . In this embodiment, the edges of the top glass and the substrate glass are flush, and a downtilt is made on the top glass, and a low-melting point glass strip is placed between the downtilt position of the top glass and the substrate glass. The glass type strip can leave a gap as shown in embodiment 1, also can make gap on the low-melting point glass powder type strip as shown in embodiment 2, its function is identical with embodiment 1.

[0032] The above-mentioned glass powder strips can also be replaced by low-melting glass powder piles, which have basically the same effect and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com