Honeycomb plate

A technology of honeycomb panels and panels, applied in the direction of coating, layered products, powder coatings, etc., can solve the problems of complicated edge banding process, unsuitable for honeycomb panels, and impossibility of thick coating, etc., to achieve simple and convenient edge banding process, The effect of meeting the mechanical strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

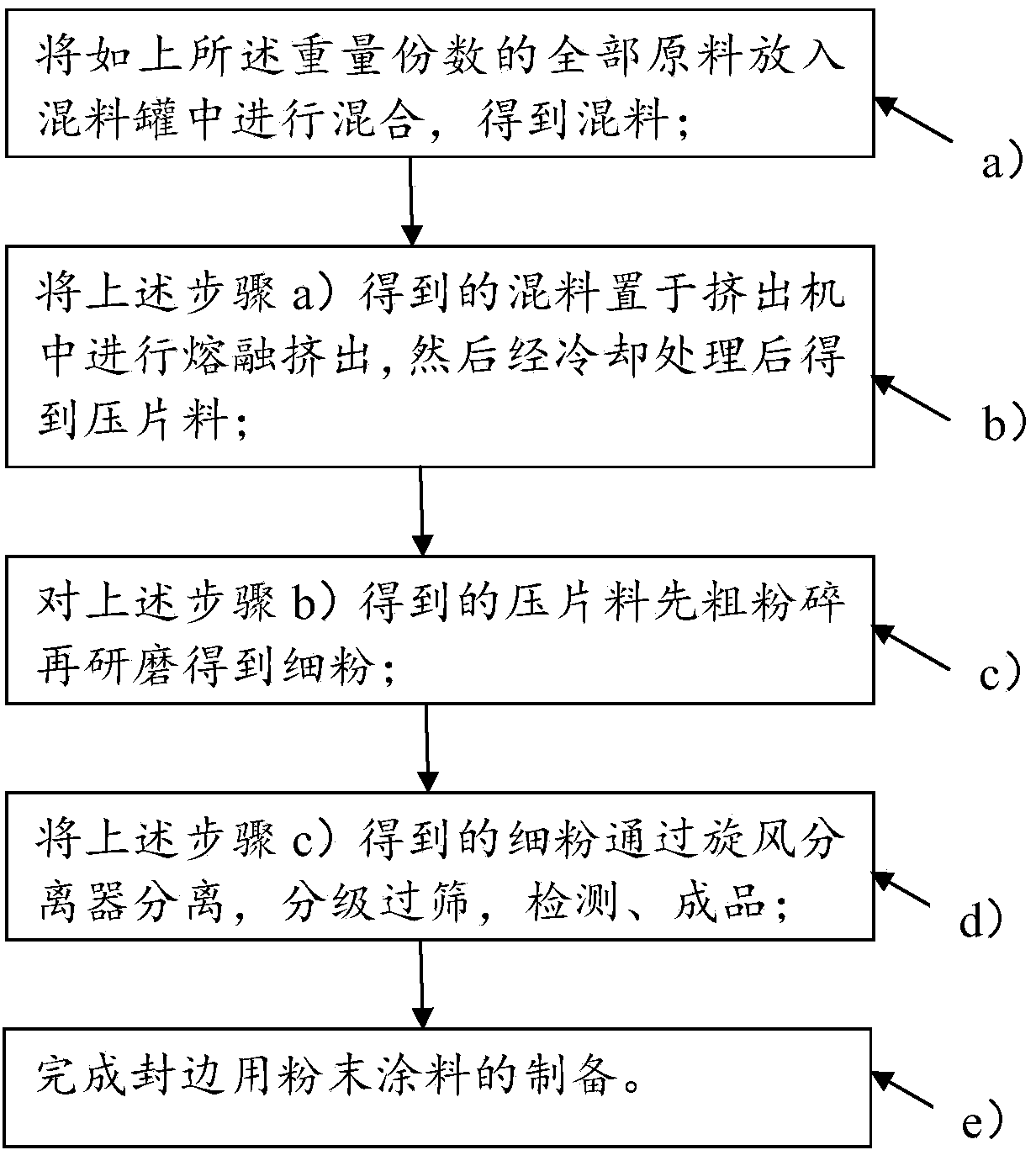

Method used

Image

Examples

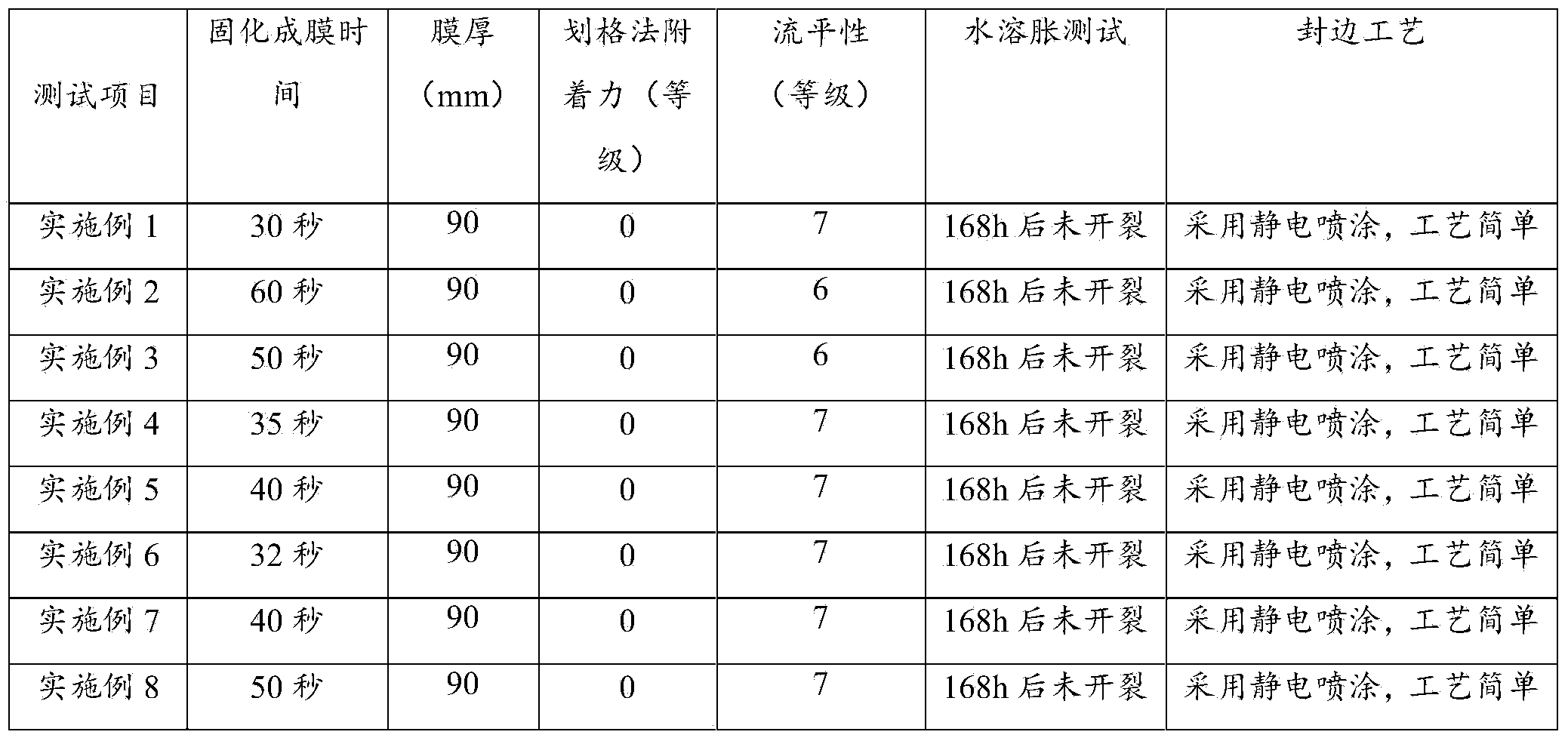

Embodiment 1

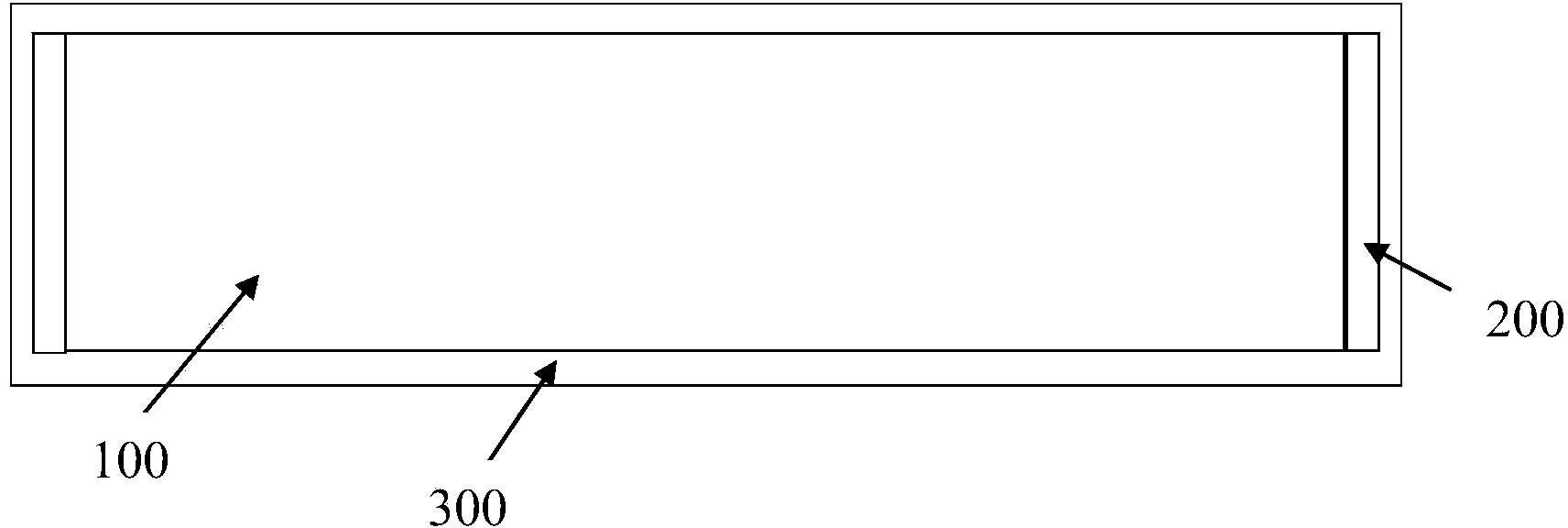

[0050] See figure 2 As shown, a honeycomb panel includes a honeycomb panel body 100, the side of the panel body has an edge-seal coating 200, and a thermosetting coating 300 is provided on the edge-seal coating 200 and the surface of the panel body 100, wherein the edge-seal coating The layer 200 is obtained by electrostatic spraying and infrared spectrum curing on the side of the plate body 100 with powder coating for edge sealing. The specific wavelength range of the infrared spectrum is 100-300 μm. Certainly, in other specific implementation manners, infrared spectra of other specific wavelength ranges may also be selected.

[0051] In this embodiment, the powder coating for edge sealing includes the following raw materials in parts by weight:

[0052] 63 parts of epoxy resin, wherein, epoxy resin is prepared by adopting semi-crystalline or full crystallization or superesterification process, and is used to reduce viscosity and improve curing speed. Specifically, in this ...

Embodiment 2

[0066] The rest of the technical solutions of this embodiment 2 are the same as those of the above-mentioned embodiment 1, the only difference being that the powder coating for edge sealing includes the following raw materials in parts by weight:

[0067] 25 parts of epoxy resin;

[0068] 20 parts of curing agent;

[0069] 35 parts of pigments and fillers;

[0070]20 parts of auxiliary agent, specifically, in this embodiment, the auxiliary agent includes 3 parts of leveling agent, 5 parts of rheological agent, 5 parts of viscosity reducer, 3 parts of degassing agent and 4 parts of defoamer.

Embodiment 3

[0072] The remaining technical solutions of this embodiment 3 are the same as those of the above-mentioned embodiment 1, and the only difference is that the powder coating for edge sealing includes the following raw materials in parts by weight:

[0073] 30 parts of epoxy resin;

[0074] 18 parts of curing agent;

[0075] 32 parts of pigments and fillers;

[0076] 20 parts of auxiliary agent, specifically, in this embodiment, the auxiliary agent includes 3 parts of leveling agent, 5 parts of rheological agent, 5 parts of viscosity reducer, 3 parts of degassing agent and 4 parts of defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com