Automatic positioning, edge sealing and edge trimming system for furniture plate

An automatic positioning and trimming technology, which is applied to household components, manufacturing tools, wood processing appliances, etc., to achieve the effect of saving manpower and material resources, good glue coating effect, and uniform glue coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

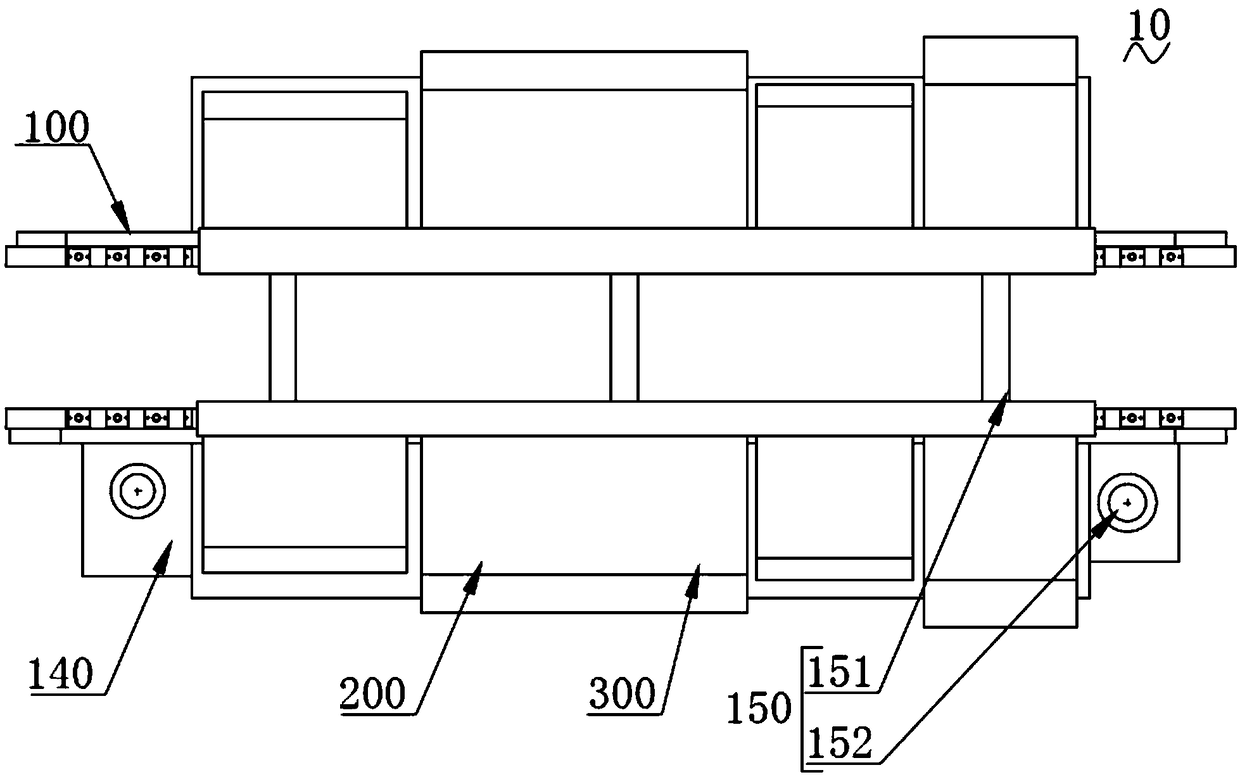

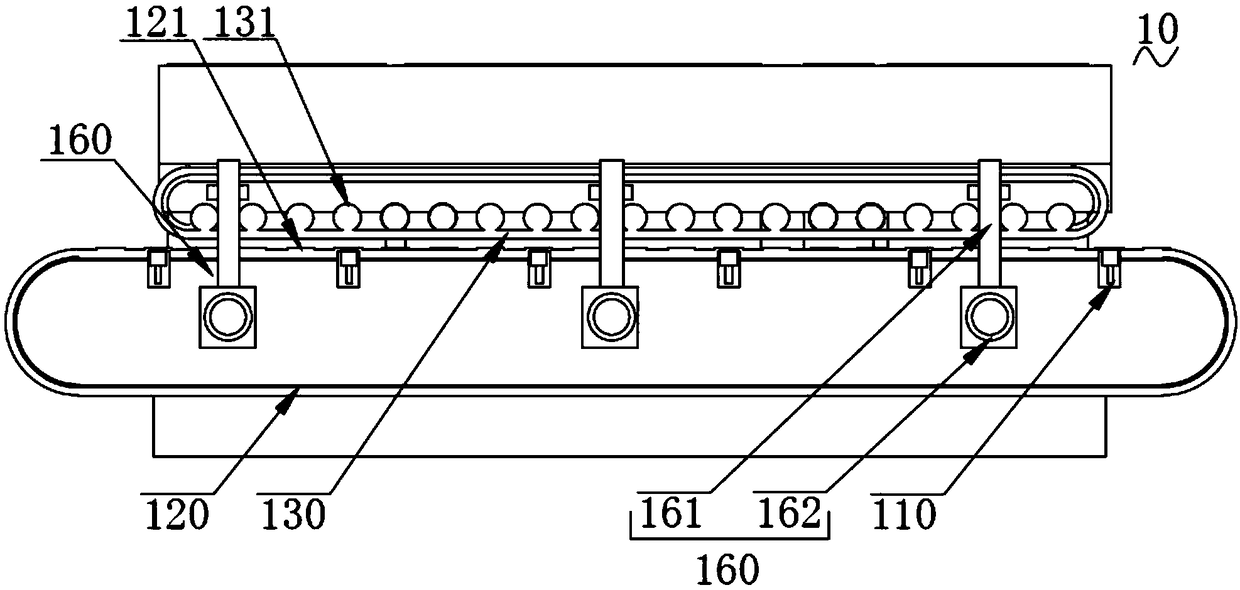

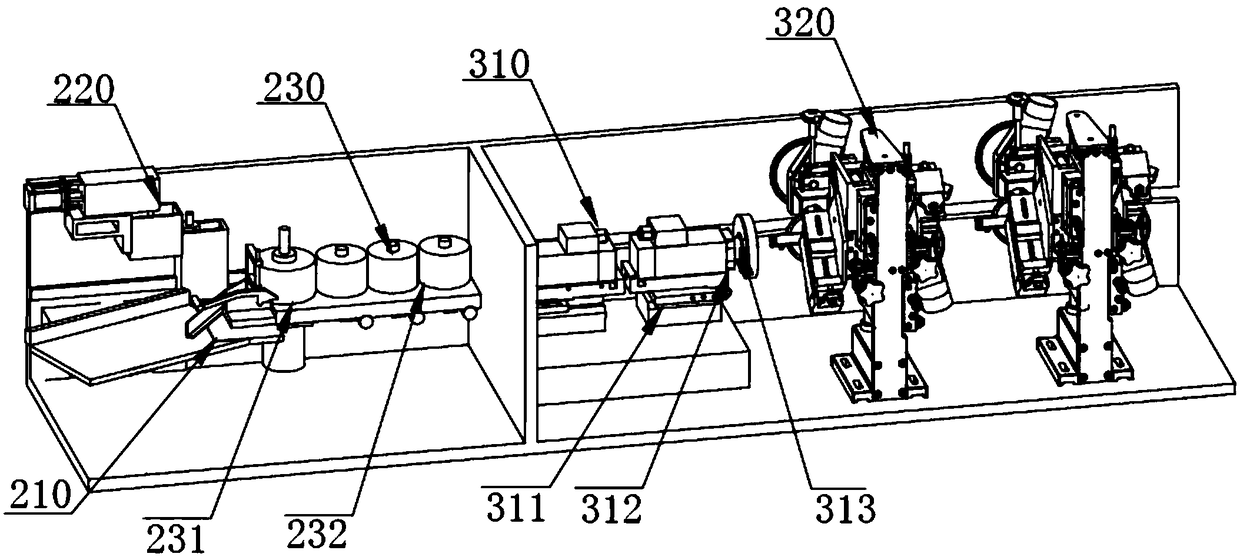

[0026] Such as Figure 1 ~ Figure 3 As shown, a furniture panel automatic positioning edge banding and trimming system 10 includes a conveying device 100, an edge banding device 200 and an edge trimming device 300 symmetrically arranged on both sides of the conveying device 100, and the conveying device 100 includes a conveyor belt. The conveyor belt is provided with a positioning assembly 110 for positioning and trimming the edge of the plate; the edge sealing device 200 includes a belt unwinding assembly 210 for unwinding the edge sealing belt, and a gluing assembly 220 for applying glue to the edge of the plate. The edge banding is pressed against the pressing assembly 230 of the plate, the edge trimming device 300 includes a cutting assembly 310 for cutting the edge banding, an edge trimming assembly 320 for trimming the cut edge banding, the gluing assembly 220 L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com