Device special for real-time and automatic edge sealing of corrugated line adhesive tape and manufacturing method

A special equipment and corrugated line technology, applied in the field of corrugated line tape real-time automatic edge sealing special equipment, can solve the problems of time-consuming and low efficiency, and achieve the effect of improving edge sealing quality, improving work efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

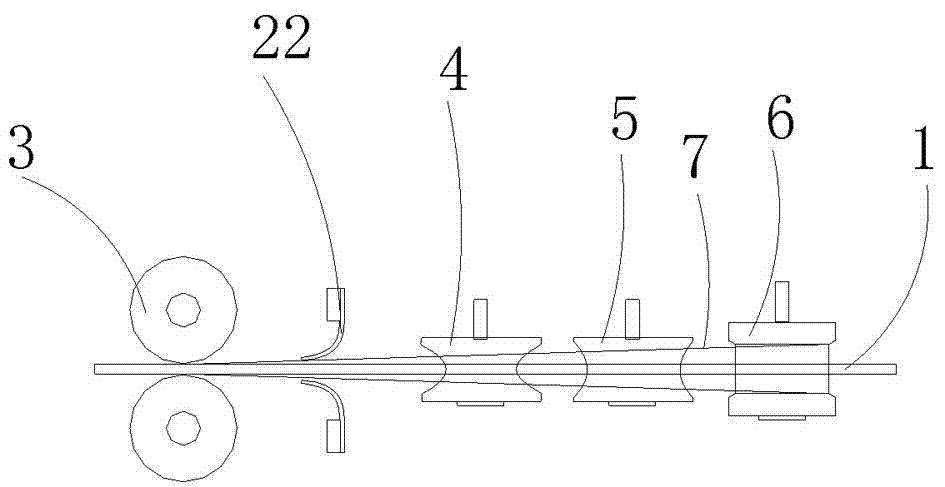

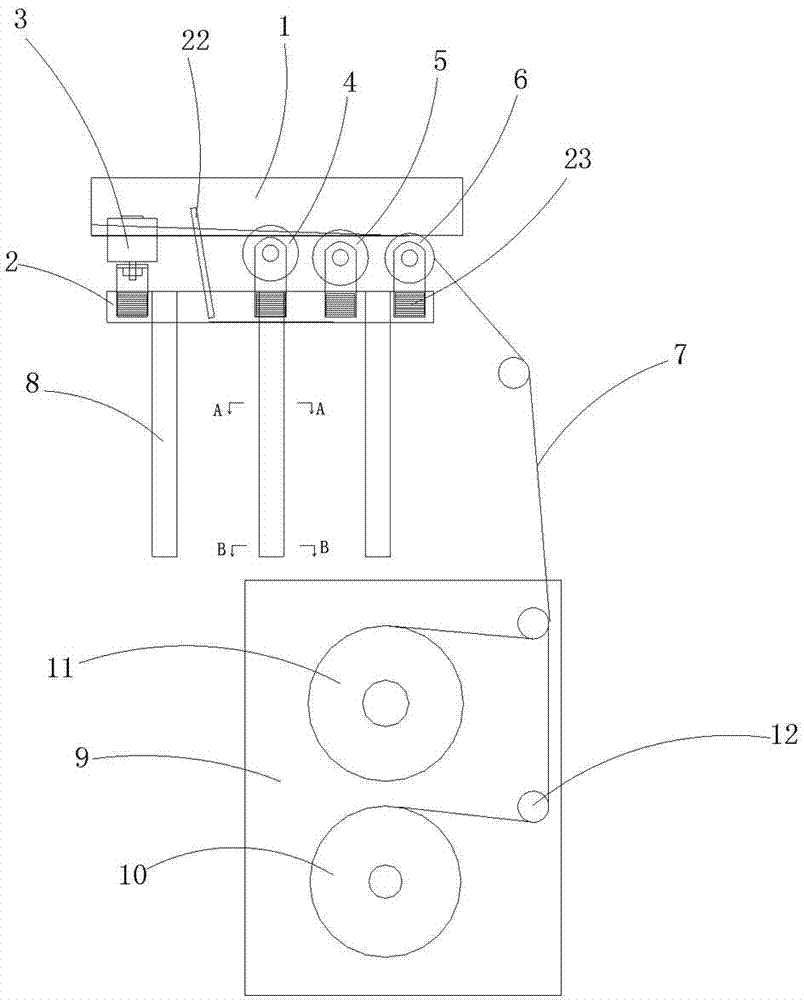

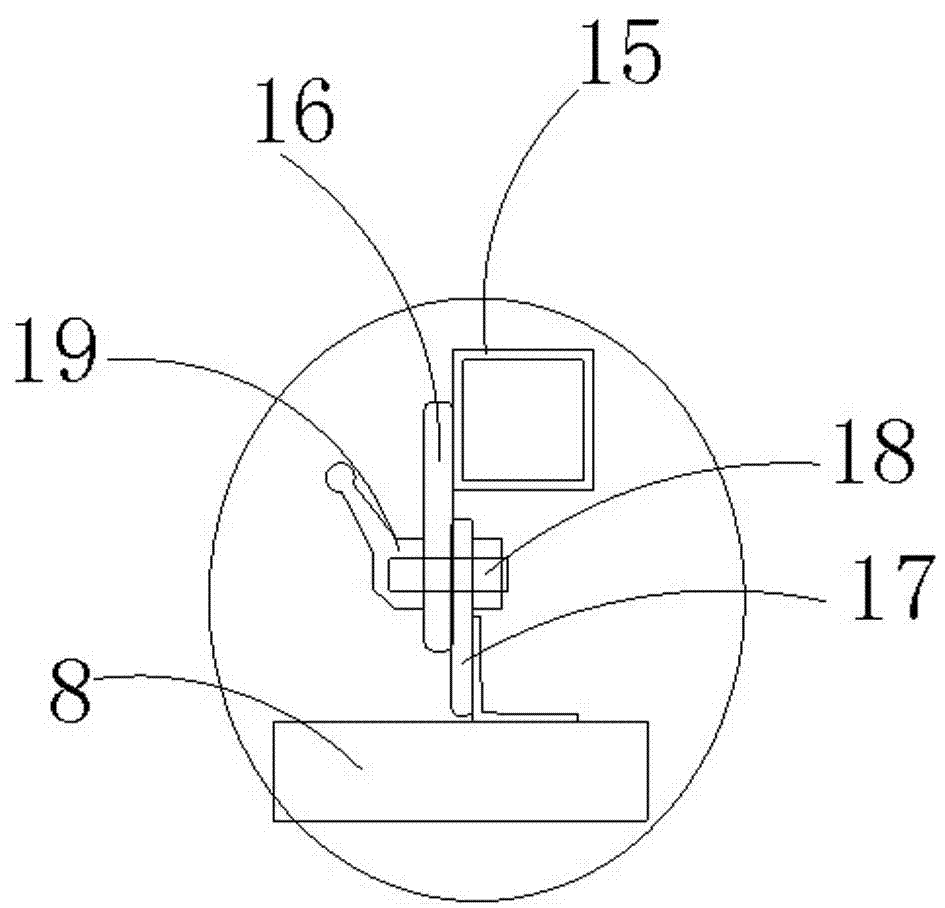

[0033] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 as shown,

[0034] A special equipment for real-time automatic edge banding of corrugated tape, including corrugated cardboard 1, and also includes a support bracket 2, the left end of the support bracket 2 is provided with a pair of symmetrically distributed pressing wheels 3, the support bracket 2 The right end is provided with the third arc guide wheel 4, the second arc guide wheel 5 and the first arc guide wheel 6 successively from left to right, and the corrugated cardboard 1 follows the second arc guide wheel 5 successively from the first arc guide wheel 6 3. The third arc guide wheel 4 moves forward, and the corrugated cardboard 1 enters the pressure roller 3 after passing through the third arc guide wheel 4. The two sides of the corrugated cardboard 1 are respectively provided with adhesive tapes 7, and the adhesive tape 7 passes thr...

Embodiment 2

[0051] Embodiment 2: A special equipment for real-time automatic edge banding of corrugated tape, including a corrugated cardboard 1, and a support bracket 2. The left end of the support bracket 2 is provided with a pair of symmetrically distributed pressing wheels 3. The described The right end of the supporting bracket 2 is provided with the third arc guide wheel 4, the second arc guide wheel 5 and the first arc guide wheel 6 successively from left to right, and the corrugated cardboard 1 is sequentially along the second arc guide wheel 6 from the first arc guide wheel. The arc guide wheel 5 and the third arc guide wheel 4 are displaced forward, and the corrugated cardboard 1 enters between the pressure rollers 3 after passing through the third arc guide wheel 4. The two sides of the corrugated cardboard 1 are respectively provided with adhesive tapes 7. The adhesive tape 7 is bonded to the corrugated cardboard 1 through the pressure roller 3, the adhesive tape 7 is conveyed ...

Embodiment 3

[0068] Embodiment 3: A special equipment for real-time automatic edge banding of corrugated tape, including corrugated cardboard 1, and also includes a support bracket 2, the left end of the support bracket 2 is provided with a pair of symmetrically distributed pressing wheels 3, the described The right end of the supporting bracket 2 is provided with the third arc guide wheel 4, the second arc guide wheel 5 and the first arc guide wheel 6 successively from left to right, and the corrugated cardboard 1 is sequentially along the second arc guide wheel 6 from the first arc guide wheel. The arc guide wheel 5 and the third arc guide wheel 4 are displaced forward, and the corrugated cardboard 1 enters between the pressure rollers 3 after passing through the third arc guide wheel 4. The two sides of the corrugated cardboard 1 are respectively provided with adhesive tapes 7. The adhesive tape 7 is bonded to the corrugated cardboard 1 through the pressure roller 3, the adhesive tape 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer circle diameter | aaaaa | aaaaa |

| Inner circle diameter | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com