Mechanical plate shearing machine

A shearing machine, mechanical technology, applied in shearing machine equipment, shearing device, metal processing equipment and other directions, can solve the problems of short shearing stroke, increase production cost, etc., to improve forming quality, improve production efficiency, guarantee Effects of Linearity and Parallelism Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

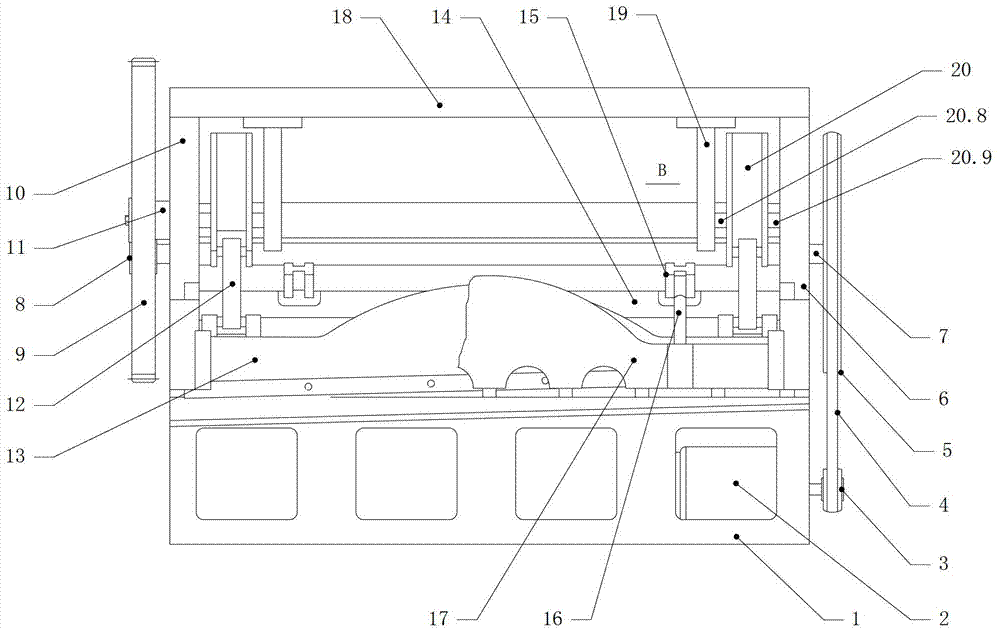

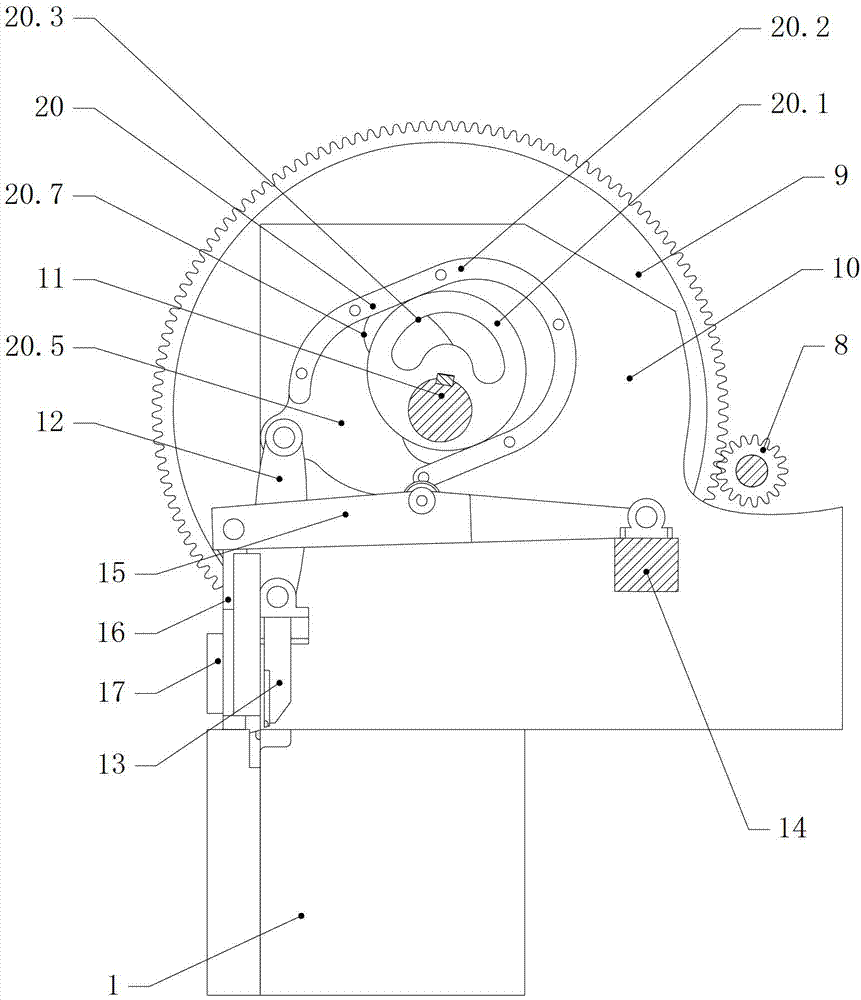

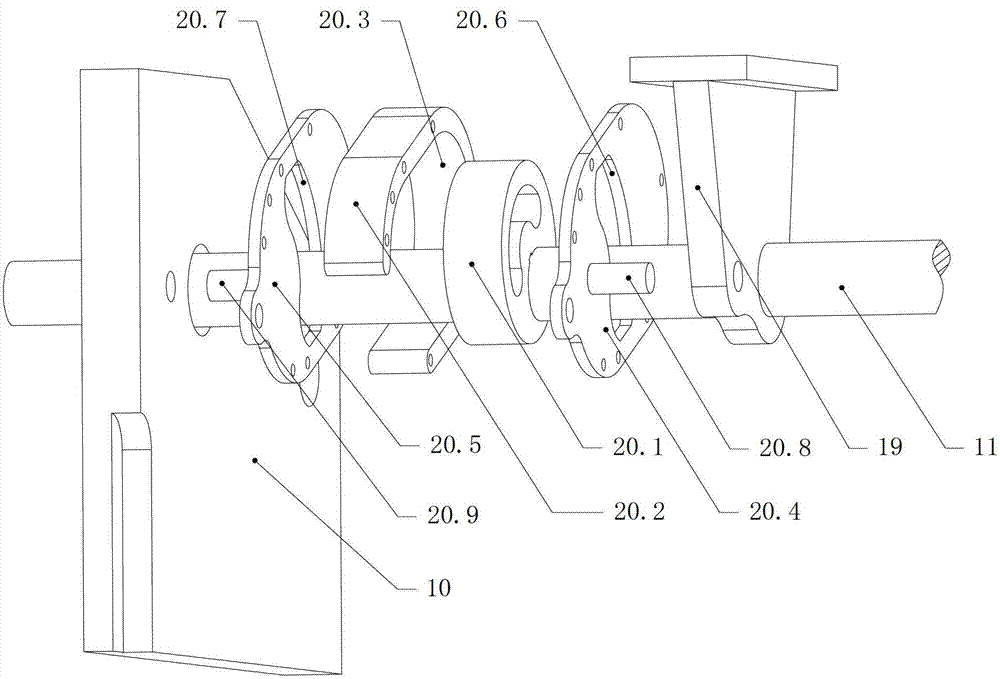

[0019] The specific embodiment of the present invention is as shown in accompanying drawing, is made of base 1, motor 2, small pulley 3, belt 4, large pulley 5, side support 16, power transmission shaft 7, pinion 8, bull gear 9, side support II10, main shaft 11, connecting rod 12, cutter 13, beam 14, support rod 15, pressing guide rod 16, pressing frame 17; the motor 2 is installed and fixed on the side of the base 1; the small pulley 3 and the motor 2 The output ends are fixed together; the transmission shaft 7 is installed on the side bracket I6 and the side bracket II10 through bearings, one end of which is fixed with the center of the large pulley 5, and the other end is fixed with the center of the pinion 8; the large pulley 5 passes through The belt 4 is connected with the small pulley 3; one end of the main shaft 11 is installed on the side bracket II10 through a bearing, and is fixed together with the center of the large gear 9, and the other end is installed on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com