Novel balloon expandable stent conveying system

A delivery system and a new type of technology, applied in the field of medical devices, to achieve the effects of cost saving, simple structure and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

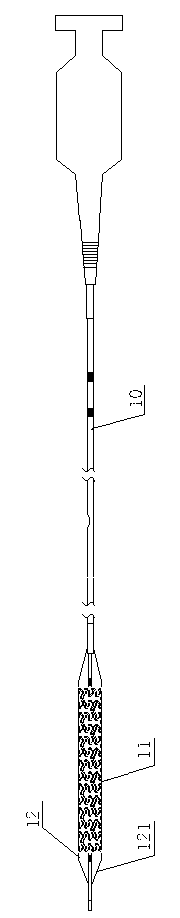

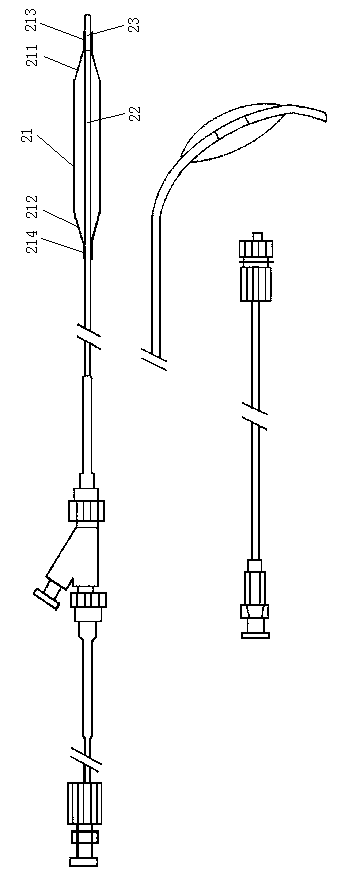

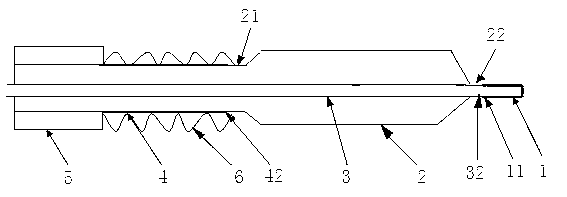

[0053] Such as image 3 , Figure 4 As shown, the present invention is a novel stent delivery system in which the stent is preloaded on the outer tube at the distal end of the balloon catheter. 5 and hypotubes. The inner tube 3 runs through the lumen of the distal outer tube 4 and the lumen of the bulb 2. The inner diameters of the soft tip 1 and the inner tube 3 are consistent, and the proximal end 11 of the soft tip 1 and the farthest end 32 of the inner tube 3 are butt-welded together. The combination of the soft head 1 and the inner tube 3 is put into the distal neck 22 of the ball 2 and welded together. And the farthest end 42 of the outer tube 4 of the far end is inserted into the proximal neck 21 of the ball 2 and welded together. The far and near ends of the inner tube 3 have heavy metal marks (developing rings) that are well developed by X-rays respectively, which are used to show the positions of the ball and the bracket. The traditional balloon expandable stent...

Embodiment 2

[0061] In this embodiment, a double-layer spherical structure is adopted, the outer layer is ePTFE with a thickness of 20 microns, and the inner layer is Nylon 12 with a thickness of 20 microns. Before use, the maximum outer diameter of the ball is 1.5 mm, and the outer diameter is 8.0 mm when fully filled to 6 atmospheres.

[0062] After use, the ball will be in a cylindrical shape with a maximum outer diameter of 1.9mm after being completely sucked, which is only slightly increased than before use. The measured burst pressure of the ball is 16 atmospheres.

[0063] The traditional single-layer Nylon 12 ball has a similar thickness (30 microns) and the same size material. Before use, the outer diameter of the folded ball is 1.7 mm, and the outer diameter is 8.0 mm when it is fully filled to 6 atmospheres. After use, the bulb becomes a flat flake-like structure after being completely vacuumed, with a maximum width of 7.5 mm, which is more than 4 times larger than the diameter...

Embodiment 3

[0067] In this embodiment, a double-layer spherical structure is adopted, the outer layer is ePTFE with a thickness of 20 microns, and the inner layer is PU with a thickness of 20 microns. Before use, the outer diameter of the ball is 1.6 mm, and when fully filled to 6 atmospheres, the outer diameter is 10.0 mm.

[0068] After use, the outer diameter of the ball is 2.0 mm, which is only slightly increased than before use.

[0069] The measured burst pressure of the ball is 12 atmospheres.

[0070] The traditional single-layer PU ball has the same total thickness (40 microns) and the same size material. Before use, the outer diameter of the folded ball is 1.7 mm, and the outer diameter is 10.0 mm when it is fully filled to 6 atmospheres. After use, the bulbs become flat flakes after being completely vacuumed, with an outer diameter of 4.8 mm, which is about 3 times larger than the diameter of the bulbs before use.

[0071] The measured burst pressure of the single-layer PU ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com